Maintenance

ABL1500WB-B Hardware Manual

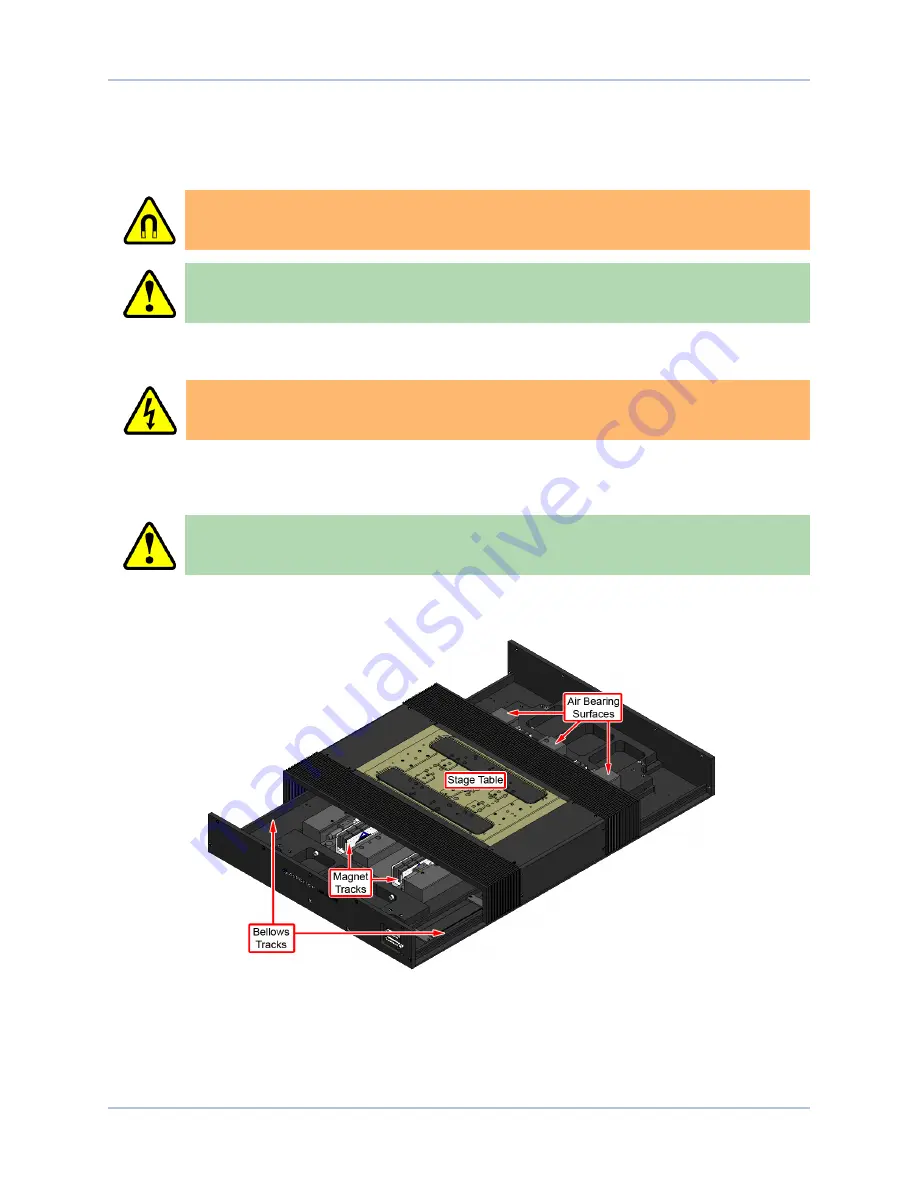

4.2.1. Cleaning Process

To clean all of the air bearing surfaces and encoder scales, it is necessary to move the stage.

D A N G E R : Strong rare-earth magnets are present in the linear motor magnet track. Loose

metal objects (tools, watches, keys, etc.) may cause personal injury and/or damage to the

equipment.

W A R N I N G : Do not attempt to move the carriage of the ABL1500WB-B until the air supply,

detailed in

, has been installed. Moving the stage table without air supplied can

cause permanent damage to the stage.

1. Blow off the stage with clean, dry, compressed air, and remove any visible debris on the outside of the

stage. Move the stage to one end of travel and remove power.

D A N G E R : To minimize the possibility of bodily injury or death, disconnect all electrical

power prior to performing any maintenance or making adjustments to the equipment.

2. Unbolt the bellows from both endplates. Clean all of the surfaces that you can access. Make sure to

use the correct solvent on each surface (refer to

). When the surface is fully dry, move the

stage by hand to the opposite end of travel.

W A R N I N G : Make sure that all solvent has completely evaporated before attempting to

move the stage. Even the slightest amount of solvent could cause damage to the air bearing

surfaces, clog the air ducts, or damage the electronics of the stage.

3. This should expose all previously covered surfaces. Repeat the cleaning process. Re-secure the

bellows into the stage endplates. Restore power to the stage after all solvents are fully dry.

Figure 4-1:

Air Bearing Surfaces and Encoder Scales Require Periodic Cleaning

42

Chapter 4

www.aerotech.com