BM/BMS Series Hardware Manual

Introduction

www.aerotech.com 1-11

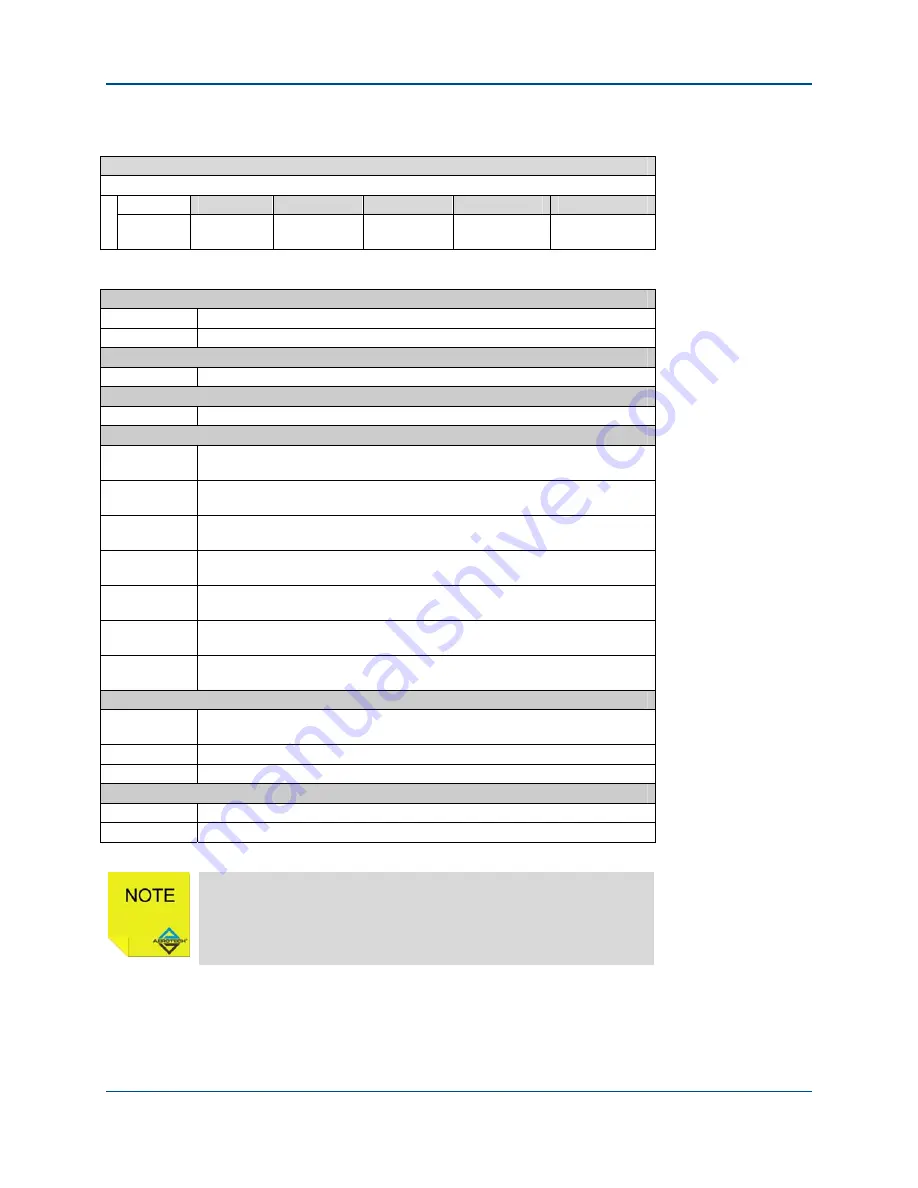

Table 1-5:

BMS Motor Part Number and Ordering Example (BMS280 – BMS465)

Ordering Example

BMS280-AH-MS-E2000H-BK2

Where:

280

-AH

-MS

-E2000H

-BK2

Motor

Torque

Motor

Winding

Connector

Type

Feedback

Option

Options

Table 1-6:

BMS Motor Options (BMS280 – BMS465)

BM Series Rotary Servo Motors

BMS280

NEMA 23 – Tcont = 227.0 oz-in brushless motor

BMS465

NEMA 23 – Tcont = 404.8 oz-in brushless motor

Winding Options

-AH

Standard

w

inding with Hall board, required with AS style encoders

Connectors

-MS

Military

-s

tyle connectors for feedback and motor power

Feedback Options

-E1000H

1000 line incremental squarewave encoder w/ marker & hall effect track

RS-422 line driver output

-E2000H

2000 line incremental squarewave encoder w/ marker & hall effect track

RS-422 line driver output

-E2500H

2500 line incremental squarewave encoder w/ marker & hall effect track

RS-422 line driver output

-E5000H

5000 line incremental squarewave encoder w/ marker & hall effect track

RS-422 line driver output

-E500AS

500 line incremental amplified sine encoder w/ marker, requires –AH, max

speed 4800rpm

-E1000AS

1000 line incremental amplified sine encoder w/ marker, requires –AH,

max speed 2400rpm

-E1250AS

1250 line incremental amplified sine encoder w/ marker, requires –AH,

max speed 1920rpm

Options (Brushless Rotary Motors)

-BK2

Brake, Holding torque = 0.8 N-m (112 oz-in), 24 VDC, 0.3 A for BMS60,

BMS100

-NS

IP65 rated Nitrile front shaft seal

-VAC6

Vacuum prep for up to torr

-6

Accessories

MCM-3

Connector; MS motor power mate for BMS280, BMS465 motors

MCF-3

Connector; MS motor feedback mate for BMS280, BMS465 motors

Aerotech also offers a variety of brushless amplifiers.

Refer to Aerotech’s Motion Control Product Guide for more

information.

Summary of Contents for BM Series

Page 6: ...Table of Contents BM BMS Series Hardware Manual iv www aerotech com...

Page 8: ...List of Figures BM BMS Series Hardware Manual vi www aerotech com...

Page 10: ...List of Tables BM BMS Series Hardware Manual viii www aerotech com...

Page 12: ...Declaration of Conformity BM BMS Series Hardware Manual x www aerotech com...

Page 50: ...Appendix A BM BMS Series Hardware Manual A 8 www aerotech com...

Page 56: ...Index BM BMS Series Hardware Manual Index 2 www aerotech com...

Page 58: ......