DR500 Operation and Technical Manual

Set Up

Version 1.6

Aerotech, Inc.

2-31

2.7. Electrical

Installation

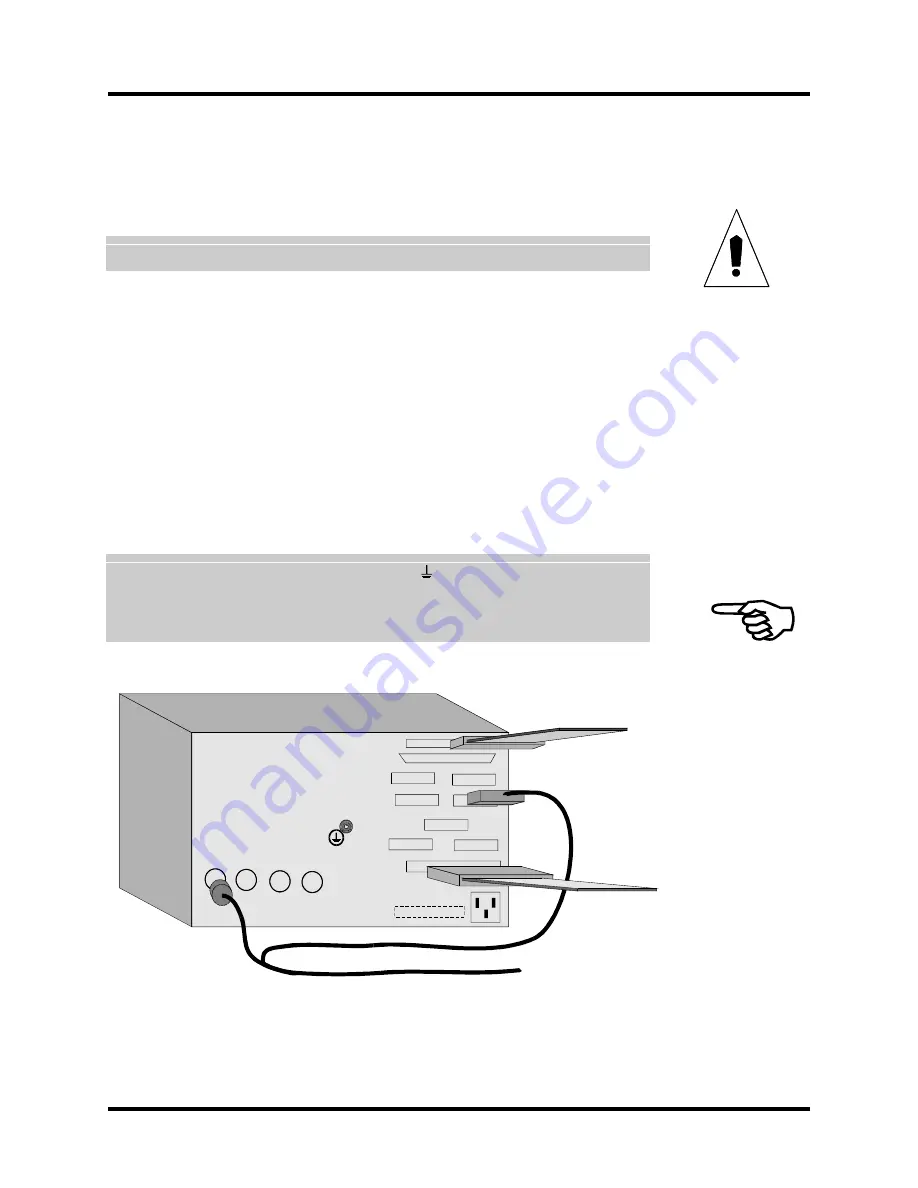

Motor, power, control, and position feedback cable connections are made to the rear of

the DR500 (refer to Figure 2-15). To make the external power connection, the AC line

cord (supplied with the DR500) is plugged into the lower right hand corner female plug.

Verify that the DR500 is configured for the correct AC line voltage.

The limit/encoder feedback connections connect to the appropriate axis, and the motor

drive connections connect to the matching motor connector. For example, the location for

the axis 1 motor connector is behind the axis 1 drive module (i.e., the axis motor

connectors on the rear of the chassis are numbered 4 through 1 from left to right). Control

connections are made through connector J1, labeled “From U500/U600 P1”.

When using an AC brushless motor or the I/O bus, use the optional DIOSR/DRC cable

that connects to P5 of the U500 or P10 of the U600 and to the rear of the DR500 to

connector J10 (labeled “From UNIDEX 500-P5/U600-P10”). This cable accommodates

Hall effect feedback devices. For applications that require resolver or inductosyn

feedback, connect these cables directly to the resolver option board within the personal

computer. When using the optional joystick or brake functions, the joystick connection is

made at connector J12 (labeled “JOYSTICK”) and the Brake connection is made at

connector J14 (labeled “BRAKE”). Refer to Figure 2-16 for an example of the electrical

connections made on the rear of the DR500.

Protective grounding (indicated by the symbol “ ”) is through the main power

connection.

The supply connection is the main power cord (the main power disconnect).

Figure 2-16.

DR500 Electrical Connections

WARNING

AXIS 4 AXIS 3 AXIS 2 AXIS 1

FROM UNIDEX 500 P5

I/O BUS / OPTO22

AXIS 1 J2 AXIS 2

AXIS 3 AXIS 4

MISC. I/O

JOYSTICK BRAKE

FROM UNIDEX 500 P1

AC TAG

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com