ECO165LM Hardware Manual

Maintenance

N O T E :

During the lubrication procedure, inspect the linear motion guides for any damage or signs of

wear.

The lubrication and cleaning process is outlined in the steps that follow.

D A N G E R : To minimize the possibility of bodily injury or death, disconnect all electrical

power prior to performing any maintenance or making adjustments to the equipment.

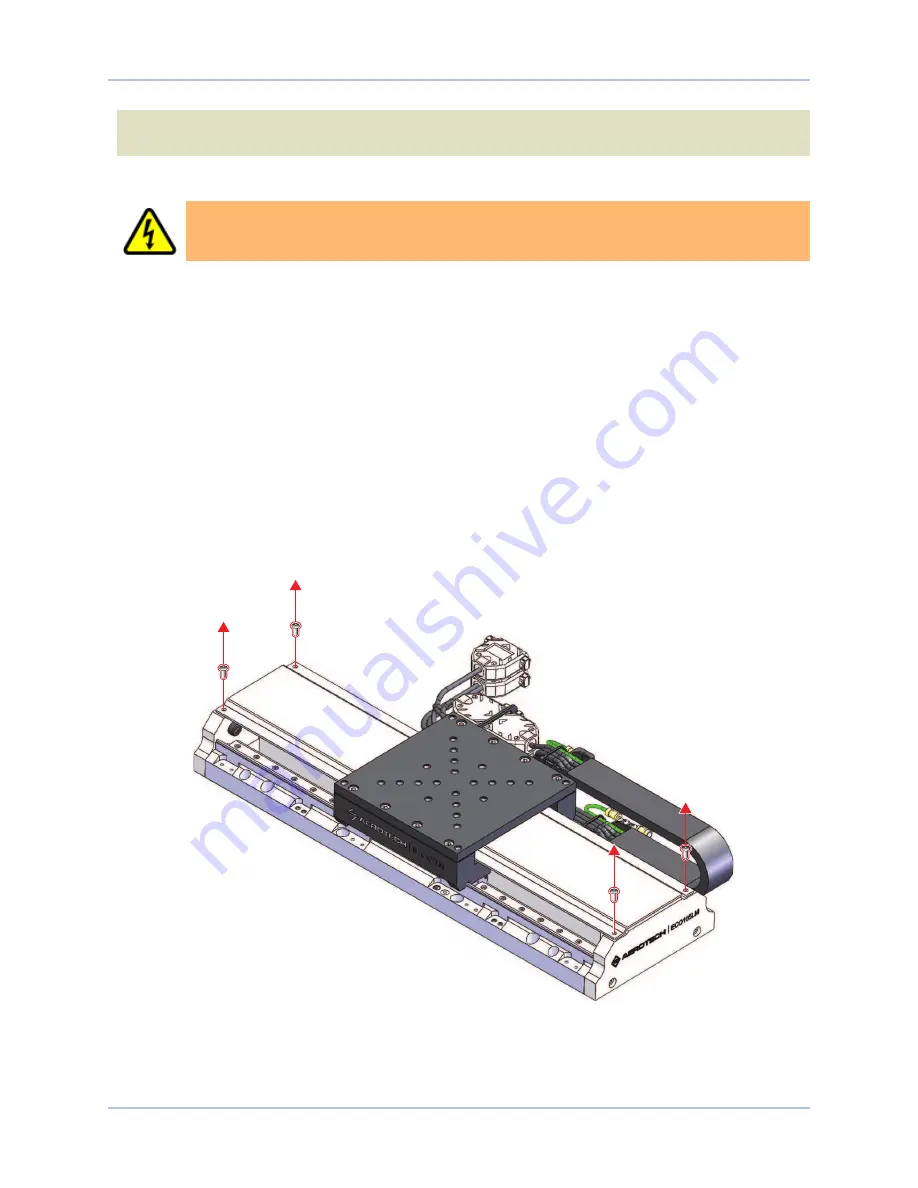

1. Remove power to the stage.

2. Remove the screws on the edges of the hardcover (

) and slide it out from under the stage

). This can be done without removing the table.

3. Remove any accumulated dust or debris from the inside of the assembly.

4. Remove any dirty or dried lubricant from the linear bearing rails. Use a clean, lint-free cloth with a side-

to-side motion. A swab soaked in Isopropyl Alcohol can be used (carefully) to remove stubborn debris.

5. Apply a thin, continuous film of lubricant to the linear bearing guides. A good quality, natural bristle

artist's brush makes an excellent applicator.

6. Manually move the stage to the opposite end of travel. This will work the grease into the linear bearing

guides.

7. Repeat steps 3 through 5 for any areas covered by the original table position.

8. Refasten the hardcover.

9. Restore power to the stage; drive the stage table back to its original position to redistribute lubricants.

Figure 4-1:

Hardcover Screw Removal

www.aerotech.com

Chapter 4

39