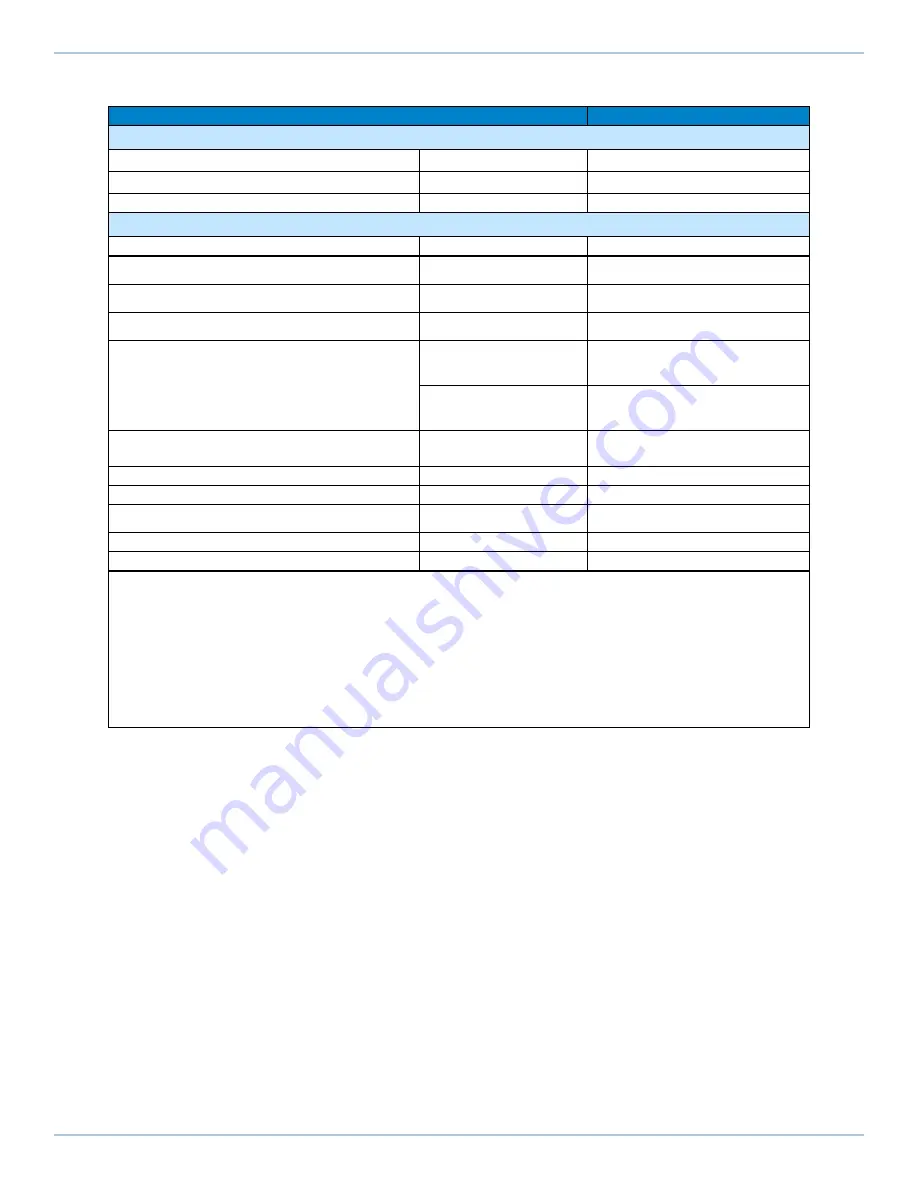

Table 3-16:

ECO225SL Motor Specifications (BMS280)

BMS280

Performance Specifications

(1, 5)

Stall Torque, Continuous

(2)

N·m (oz·in)

1.60 (227.0)

Peak Torque

(3)

N·m (oz·in)

6.41 (908.0)

Rated Power Output, Continuous

W

381

Electrical Specifications

(5)

Winding Designation

-A

BEMF Constant (Line-Line, Max)

V

pk

/k

rpm

57.0

Continuous Current, Stall

(2)

A

pk

(A

rms

)

3.8 (2.7)

Peak Current, Stall

(3)

A

pk

(A

rms

)

15.2 (10.7)

Torque Constant

(4, 8)

N·m/A

pk

(oz·in/A

pk

)

0.420

(59.70)

N·m/A

rms

(oz·in/A

rms

)

0.600

(84.50)

Motor Constant

(2, 4)

N·m/√W

(oz·in/√W)

0.179

(25.34)

Resistance, 25°C (Line-Line)

Ω

5.70

Inductance (Line-Line)

mH

1.10

Maximum Bus Voltage

V

DC

340

Thermal Resistance

°C/W

0.93

Number of Poles

--

14

1. Performance is dependent upon heat sink configuration, system cooling conditions, and ambient temperature

2. Values shown @ 75°C rise above a 25 °C ambient temperature, with housed motor mounted to a 250 mm x 250 mm x

6 mm aluminum heat sink

3. Peak torque assumes correct rms current; consult Aerotech

4. Force constant and motor constant specified at stall

5. All performance and electrical specifications ±10%

6. Maximum winding temperature is 100 °C (thermistor trips at 100 °C)

7. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient

temperatures

8. All Aerotech amplifiers are rated A

pk

; use torque constant in N·m/A

pk

when sizing

3.3. Motor and Feedback Specifications

ECO225SL Hardware Manual

38

www.aerotech.com