Electrical Specifications and Installation

LaserTurn

®

1 Hardware Manual

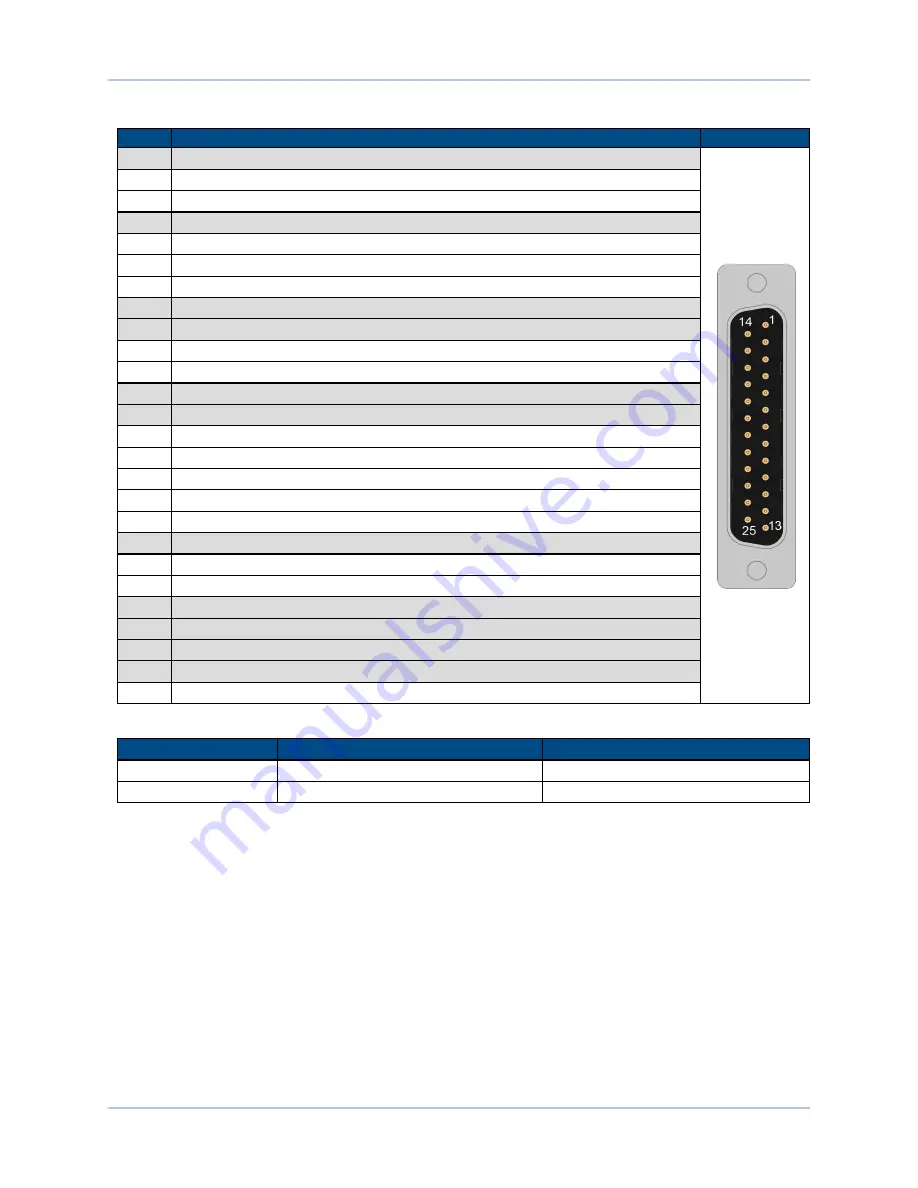

Table 3-3:

25-Pin D Feedback Connector Pinouts (Rotary Axis)

Pin

Description

Connector

1

Reserved

2

Over-Temperature Thermistor sensor

3

+5 V power supply (internally connected to Pin 16)

4

Reserved

5

Hall Effect sensor, phase B

6

Marker-N

7

Marker

8

Reserved

9

Reserved

10

Hall Effect sensor, phase A

11

Hall Effect sensor, phase C

12

Reserved

13

Reserved

14

Cosine

15

Cosine-N

16

+5 V power supply (internally connected to Pin 3)

17

Sine

18

Sine-N

19

Reserved

20

Common ground (internally connected to Pin 21)

21

Common ground (internally connected to Pin 20)

22

Reserved

23

Reserved

24

Reserved

25

Reserved

Case

Signal shield connection (to case)

Table 3-4:

25-Pin D Feedback Mating Connector

Mating Connector

Aerotech P/N

Third Party P/N

Backshell

ECK00656

Amphenol #17E-1726-2

Connector

ECK00300

FCI DB25S064TLF

28

Chapter 3

www.aerotech.com