pag.

49 di 64

Use and Maintenance Manual

M

MCCHH88--1111//EEM

M -- M

MCCHH1133--1166//EETT

Standard

Cap.7 _ Maintenance

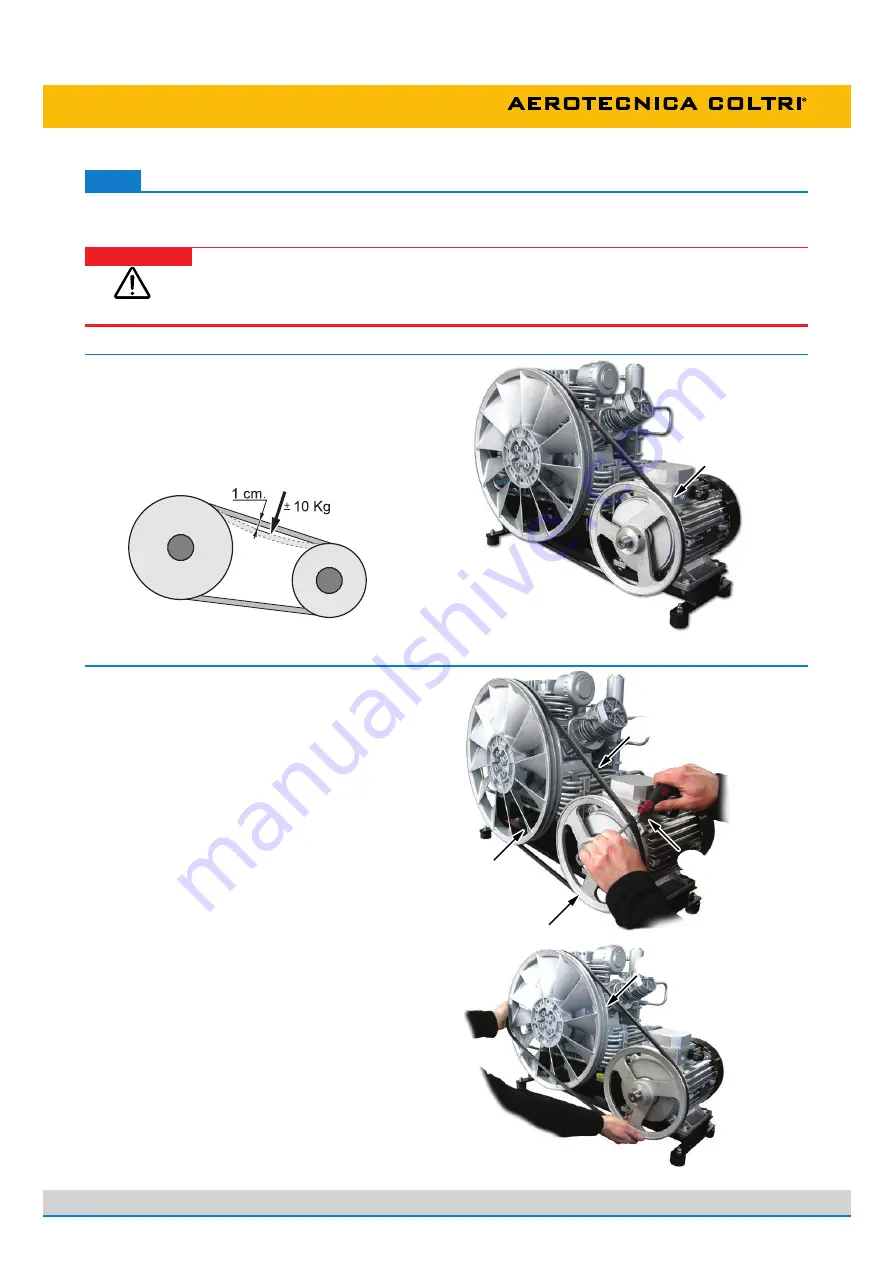

To change a belt proceed as follows:

- insert a screwdriver (

a

) between the belt (

b

) and

the motor pulley (

c

).

- take the belt out of the pulley groove.

- replace the belt with a new one, making sure that

model and length are correct: check that the

characteristics of the new belt are identical to the old

one.

- insert the belt in the groove of the motor pulley (

c

).

- insert the belt in the groove of the compressor

pulley (

d

): turn the pulley by hand until the belt slips

into the pulley groove perfectly (second diagram).

- check that the belt is inserted perfectly in the

grooves of both pulleys and that belt tension is

correct.

If the tension of the new belt still fails to comply with

the necessary requisites contact

AEROTECNICA

COLTRI

assistance service.

c

b

a

d

d

TRANSMISSION BELT

7.10

Belt tension must be checked monthly.

The transmission belts must be replaced every 500 working hours of the compressor.

DANGER

Do not carry out these tasks if the compressor has only just shut down; wait for the

compressor to cool.

All maintenance work must be carried out with the compressor OFF and the power

supply lead unplugged from the mains socket.

Checking transmission belt tension

7.10.1

To check the tension on the belt (

a

) exert a pressure

of approximately 10 Kg on the belt; check that the

belt does not flex by more than 1 cm with respect to

its original position.

Should it flex more than this replace the belt.

a

Changing transmission belt

7.10.2