Cap.3 _ Safety regulations

pag.

25

Use and maintenance manual

MCH-36

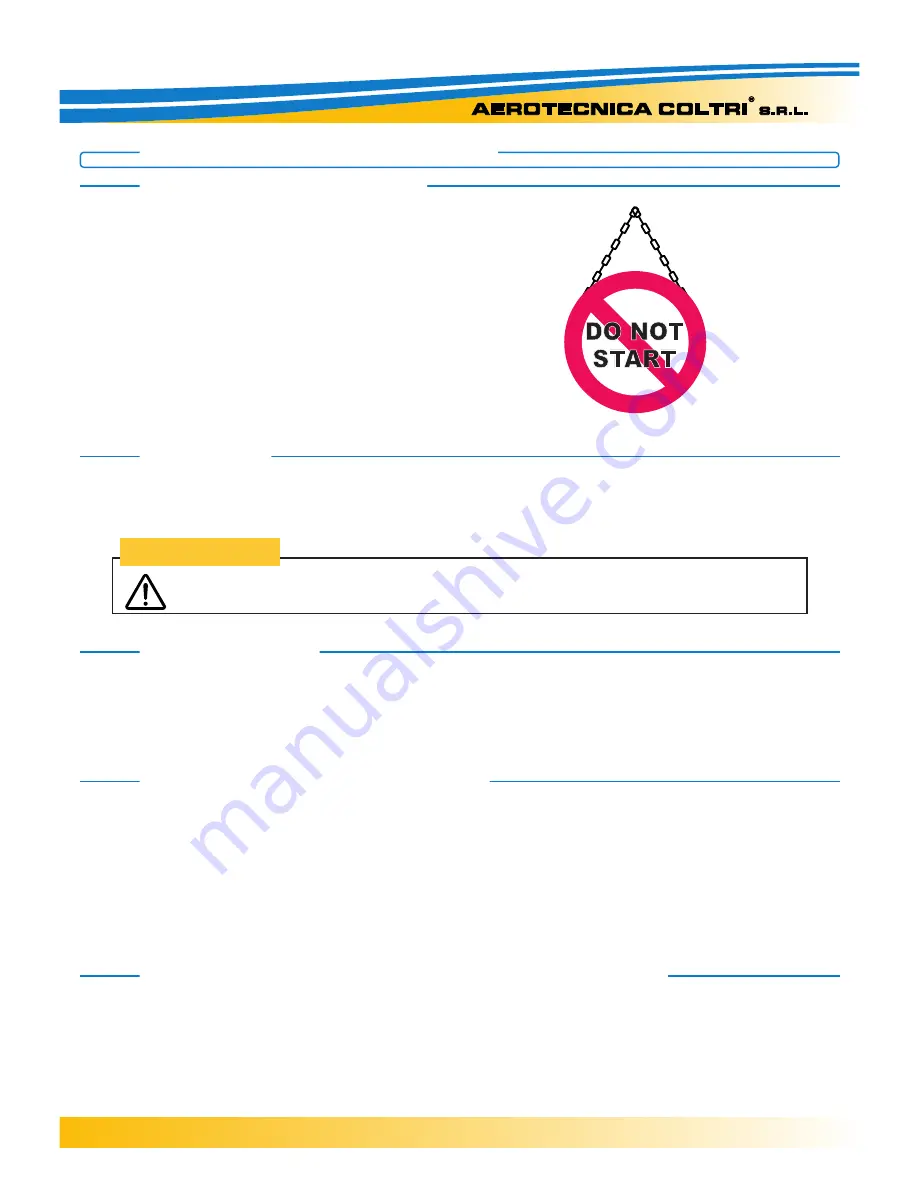

Before doing any maintenance work, stop the

engine and make sure the compressed air system is

depressurised.

If other people start the engine or act on the

control pushbuttons/keys while maintenance

work is in progress there is a risk of serious

injury or death.

To obviate these dangers always place warning

signs around the compressor before carrying out

maintenance.

The routine maintenance tasks described in this manual must only be carried out by trained, authorised

personnel.

For component maintenance/revision tasks not covered by this manual please contact

AEROTECNICA

COLTRI S.r.l.

Use only manufacturer-recommended tools; do not use worn, damaged, poor quality or improvised tools as

they can cause injury.

3.4 - MAINTENANCE PRECAUTIONS

3.4.1 - WARNING SIGNS

3.4.2 - TOOLS

3.4.3 - PERSONNEL

The manufacturer cannot be held liable for any damage or injury caused by the use of tools

that are not prescribed or modified without authorisation.

WARNING:

Oil and grease stains, scattered tools or broken pieces constitute a danger to personnel as they may cause

slips and falls. Always keep the compressor and the surrounding work area clean and tidy.

Clean the compressor with a pressurised hot water or steam jet and commercially available detergents. Do

not use diesel, petrol or solvents as the former leave an oily film that causes dust to stick while solvents (even

where weak) damage the paintwork and can lead to rust.

If the water jet gets inside the electrical parts it could, in addition to oxidising the contacts, prevent the machi-

ne being started or even cause

a sudden, unexpected start

.

For this reason

never

use water or steam jets on sensors or connectors.

Periodically check the following components, which are important for fire prevention:

- compressed air system: main compressed air circuit delivery hoses;

- bottle refill system: flex hoses for bottle refill.

Even though they may appear to be in good condition, these components must be periodically replaced with

new ones. Over time these components tend to deteriorate.

Should any of these parts prove to be faulty, replace or repair them ahead of schedule.

3.4.4 - KEEP THE COMPRESSOR CLEAN

3.4.5 - SPERIODIC REPLACEMENT OF ESSENTIAL SAFETY PARTS