Cap.7 _ Maintenance

pag.

44

Use and maintenance manual

MCH-36

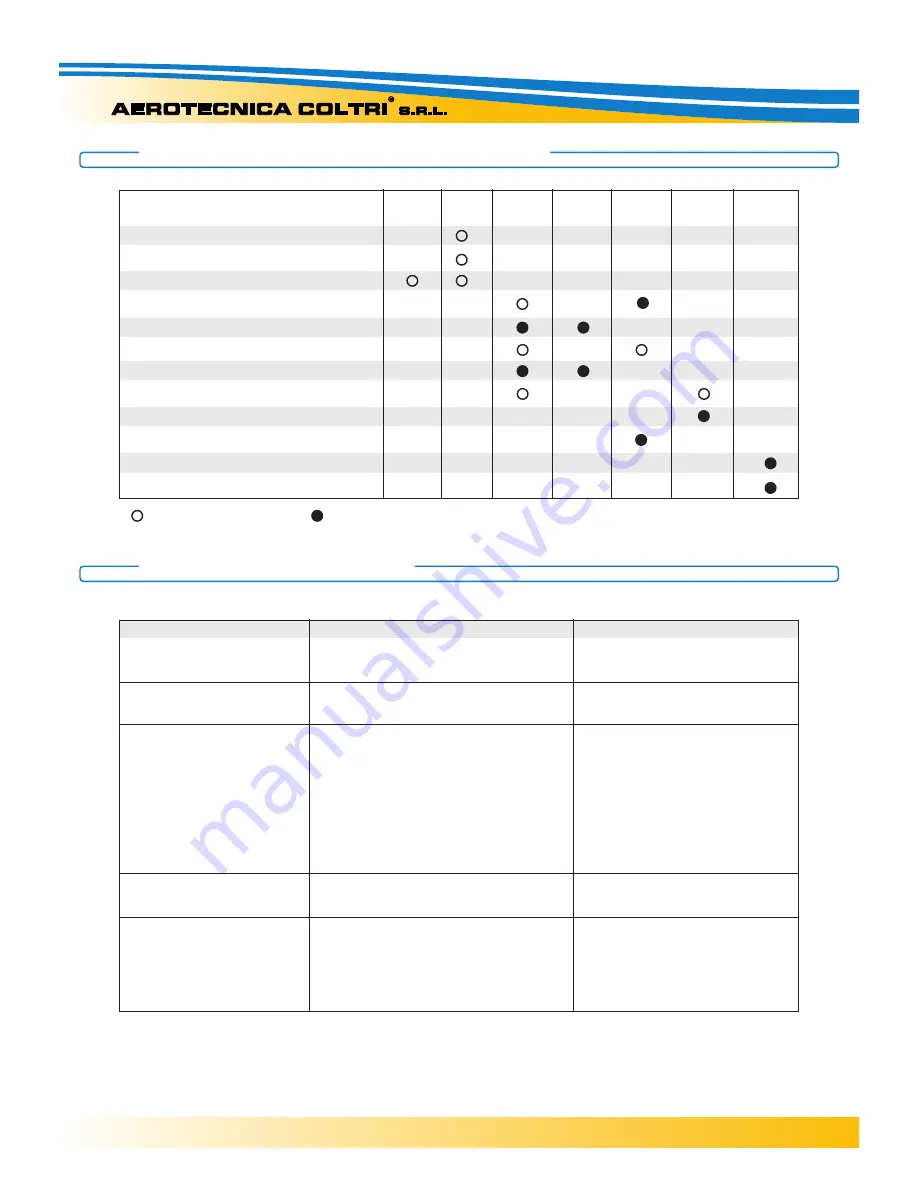

7.4 - SCHEDULED MAINTENANCE TABLE

7.5 - TROUBLESHOOTING

Every

Every

Every

250

500

1000

3000

Maintenance

5 hours

day

year

(hours) (hours) (hours) (hours)

Lubricating oil level check

Automatic shutdown check

Condensate container discharge

Belt wear and tension

Air intake filter

Fitting/hose leak check

Oil filter and oil change

Separator filter element cleaning

1st – 2nd – 3rd stage valve replacement

4th stage valve replacement

Water and HP oil separator replacement

HP filter body replacement

Problem

Cause

Solution

- The electric motor

• Phase missing

• Check fuses or condenser

does not start

- Rotation speed and flow

• Motor power too low

• Check the motor and the line

rate decrease

• The belt slips

• Restore proper belt tension

- The flow rate diminishes

• Valves not working

• Contact technical assistance

without rpm decreasing

• 4th stage piston worn

• Contact technical assistance

• Fittings loose /

• Check for leaks with soapy

leaking seals

water and eliminate them

• Intake filter clogged

• Replace filter

• Intake extension kinked

• Straighten, use stiffer pipe

• Piston or piston rings worn

• Contact technical assistance

- Air smells of oil

• Cartridge filter exhausted

• Replace

• Piston rings worn

• Contact technical assistance

- Compressor overheats

• Direction of rotation wrong

• Check direction of rotation

• Cooling tubes dirty

• Contact technical assistance

• Incomplete valve closure

• Contact technical assistance

(causing overload of another stage)

Checking and cleaning

Change