Cap.7 _ Maintenance

pag.

45

Use and maintenance manual

MCH-36

7.6 - CHECKING AND CHANGING THE LUBRICATING OIL AND FILTER

7.6.1 - OIL TABLE

Sump capacity

litres

4,5

Recommended oils

COLTRI OIL CE750

CHEMLUBE 751

After putting the compressor into service the oil filter and the lubricating oil itself must be changed after the

first 50 (fifty) working hours.

Replacement of the filter and the lubricating oil must be done every 250 hours working hours or annually.

The compressor must be placed on a solid surface with a tilt of no more than 5°.

IMPORTANT:

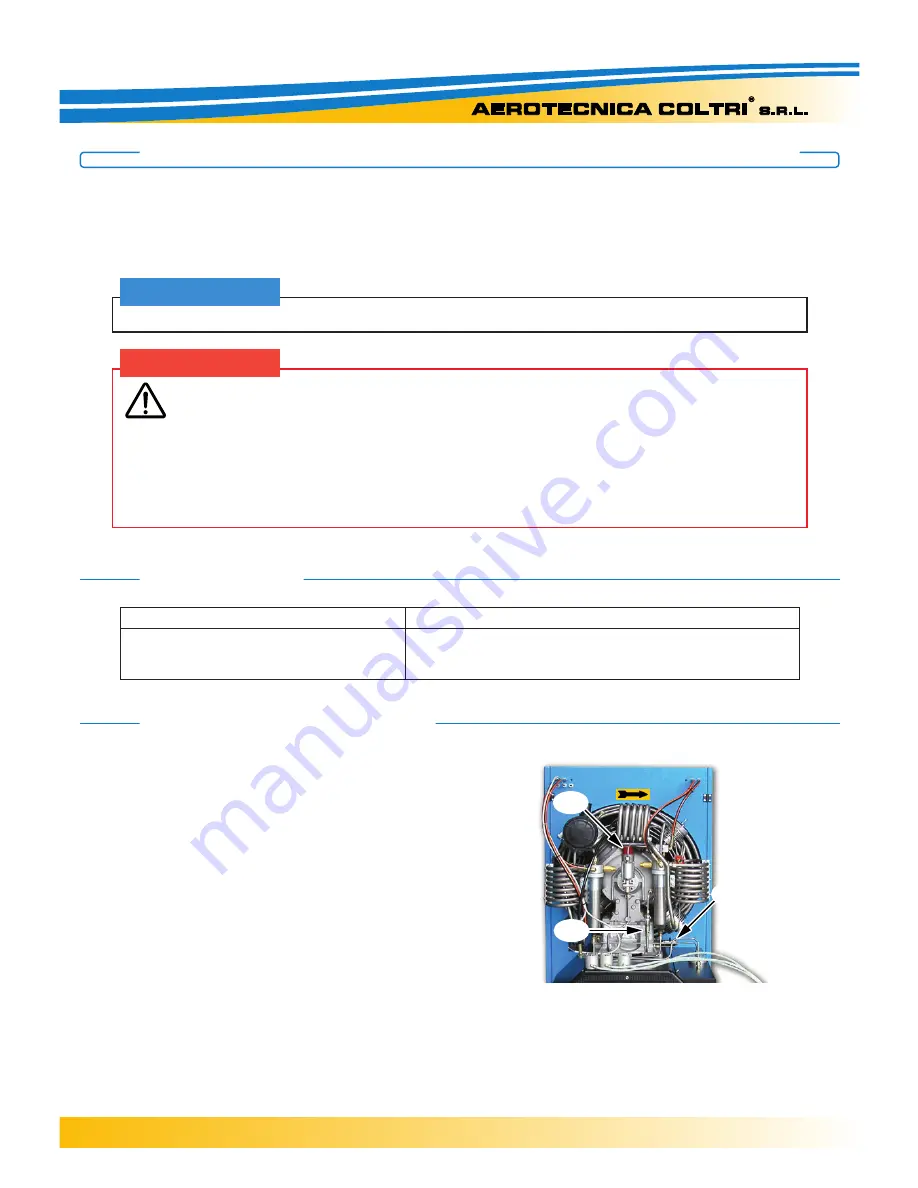

7.6.2 - CHECKING THE OIL LEVEL

The oil level must be checked every 5 working hours

of the compressor.

The oil level must be between the minimum and the

maximum shown on the oil level indicator (

a

).

If the oil level is above the maximum level:

- position a recipient under the drain tap (

b

)

so that the oil flows into the exhausted oil

recipient;

- open the drain tap and let the oil flow out

until the oil level returns within the max. and

min. limits;

- close the drain tap (

b

).

If the oil level is below the minimum level:

- open the top-up plug (

c

);

- top up with oil until the level

returns within the max. and min. limits;

- close the top-up plug (

c

).

Do not carry out these tasks if the compressor has only just shut down; wait for the

compressor to cool.

Any oil spilt during the oil/filter change could cause personnel to slip; wear protective

garments and anti-slip footwear and remove any traces of oil immediately.

Both oil and filter are classified as special wastes and must therefore be disposed of in

compliance with the anti-pollution laws in force.

All maintenance work must be carried out with the compressor OFF and the power supply lead

unplugged from the mains socket.

DANGER:

c

a

b