26

Rudder Installation

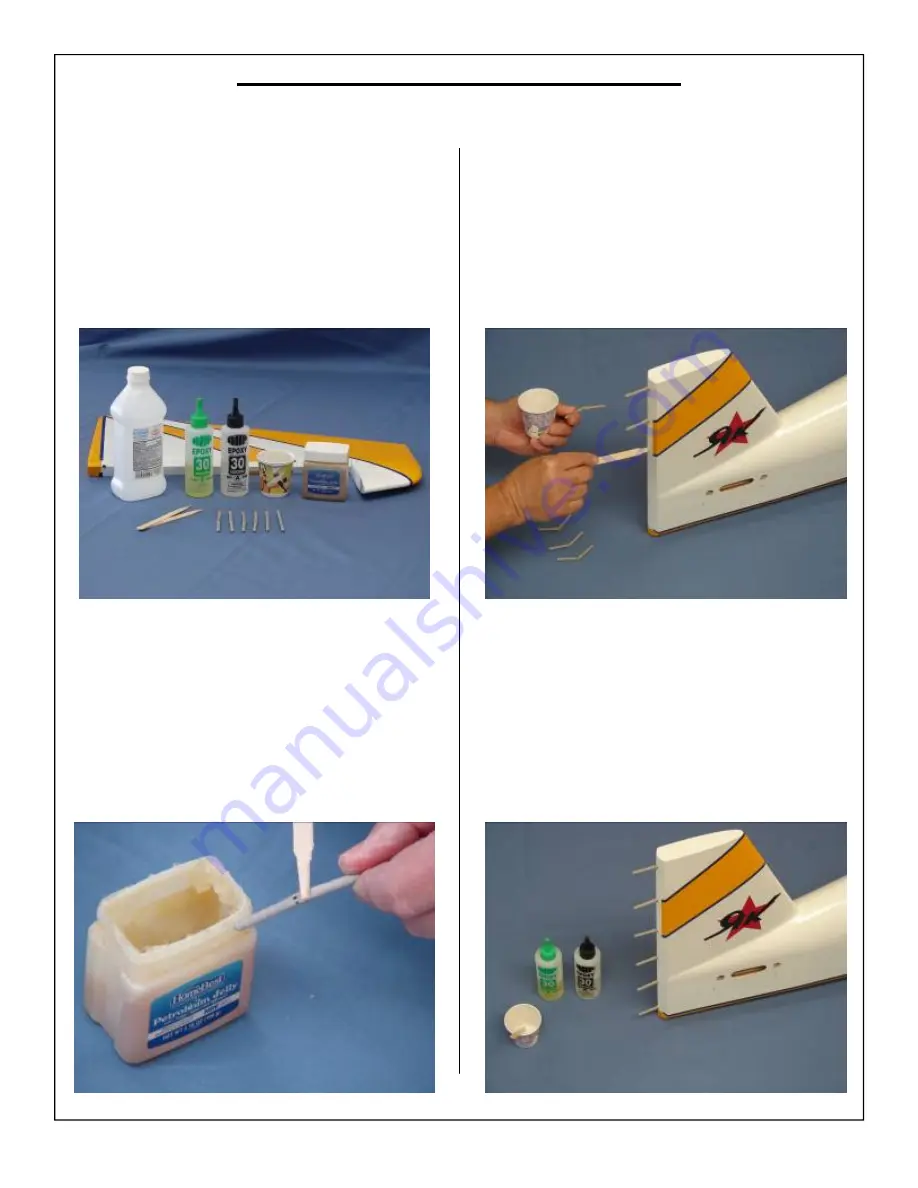

1.

Gather the rudder, hinges, epoxy, and

materials as shown. Use 15-30 minute epoxy

to ensure adequate working and cleanup time.

RUDDER AND TAILWHEEL ASSEMBLY

2.

Prep all hinges for installation by applying

Vaseline petroleum jelly or light oil to the

hinge joint. This ensures no epoxy gets into

the hinge during assembly.

3.

Mix epoxy in mixing cup and use a tapered

stick to apply the epoxy inside the pre-drilled

holes in the trailing edge of the fin. Apply

epoxy to one side of each hinge and insert the

hinge completely into the hole.

4.

Ensure the hinge axis is vertical and parallel to

the trailing edge of the fin before epoxy cures.

Wipe away excess epoxy with alcohol wetted

wipes.