38

Aeroworks 60cc Freestyle Extra 260 Assembly Manual

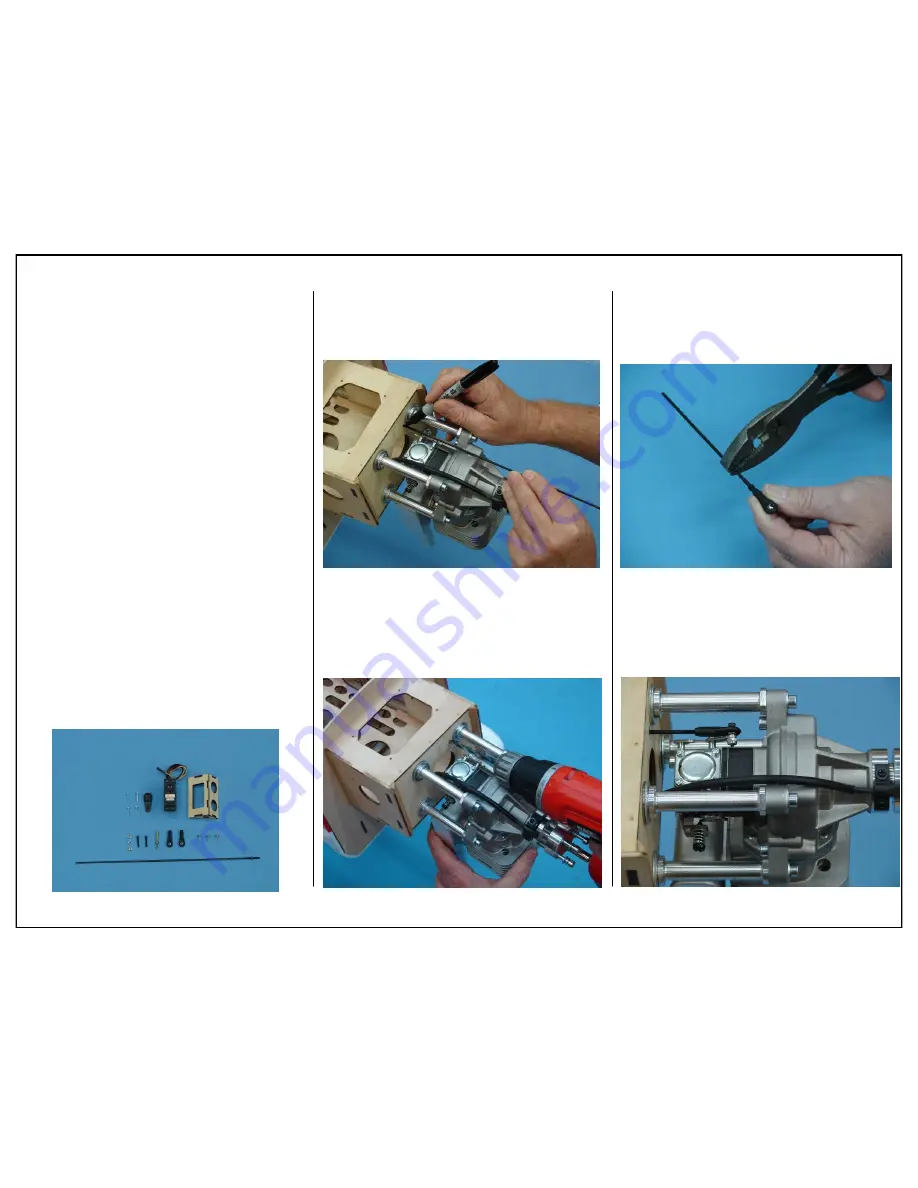

THROTTLE SERVO INSTALLATION

1. Gather the throttle items as shown below:

Required Parts - Included

1 - Prebuilt Plywood Servo Mount

1 - 4-40x300mm Threaded Pushrod

1 - 4-40 Threaded Solder Coupler

2 - 4-40 Ball Links

2 - 4-40x16mm Hex Head Bolts

2 - 4-40 Lock Nuts

1 - Brass Spacer

2 - 3mm Flat Washer

Required Parts -Not Included

1 - Throttle Servo

4 - Servo Mounting Screws (Micro Fastener

Part number

STW0209

recommended)

1 - 3/4” Servo Arm

Required Tools and Adhesives

1 - Pencil/Felt Tip Pen

1 - Phillips Screw Driver

1 - 5/64” Ball Driver

1 - Electric Drill

1 - 1/16” Drill Bit

1 - 7/64” Drill Bit

1 - Rotary Cutting Tool with Cutting Disk

1 - Wire Cutter

1 - Soldering Iron

1 - Silver Solder

“Sta-Brite Recommended”

1 - 80 Grit Sandpaper

1 - .34oz Bottle Blue IC-Loc Thread Locker

2. Mark the location of the throttle pushrod on the

firewall as shown.

3. Drill hole through firewall for the throttle push-

rod.

4. Assemble ball link to threaded end of pushrod.

Note:

Thread ball link half way onto pushrod to

allow for proper adjustment during final

installation.

5. Attach 4-40 ball link and pushrod to carburetor

throttle arm using 4-40 bolt and lock nut as

shown.