ROBOTAPE 50 ME - LH

Every 200

hours.

Transport unit

guides.

General

inspection.

Wash with

solvent, let it

dry and

lubricate.

See 7.3.

“Lubrication

point diagram”.

Every 200

hours.

Conveyor belts.

General

inspection.

Check for wear

and, if

necessary,

replace.

See 9.2.

“conveyor belt

replacement”.

Every 1000

hours.

Cutting blade.

General

inspection.

Check efficiency

and, if

necessary,

replace.

See 9.5. “blade

replacement”.

i

Danger -

Warning

The blade is very

sharp.

Every 2000

hours.

Transport unit

driving chain.

General

inspection.

Check for wear

and, if

necessary,

replace.

See 9.3. “how the

replace the

driving chain of

the transport

unit”.

Every 2000

hours.

Safety devices.

Efficiency

control.

Replace the

damaged

components.

-

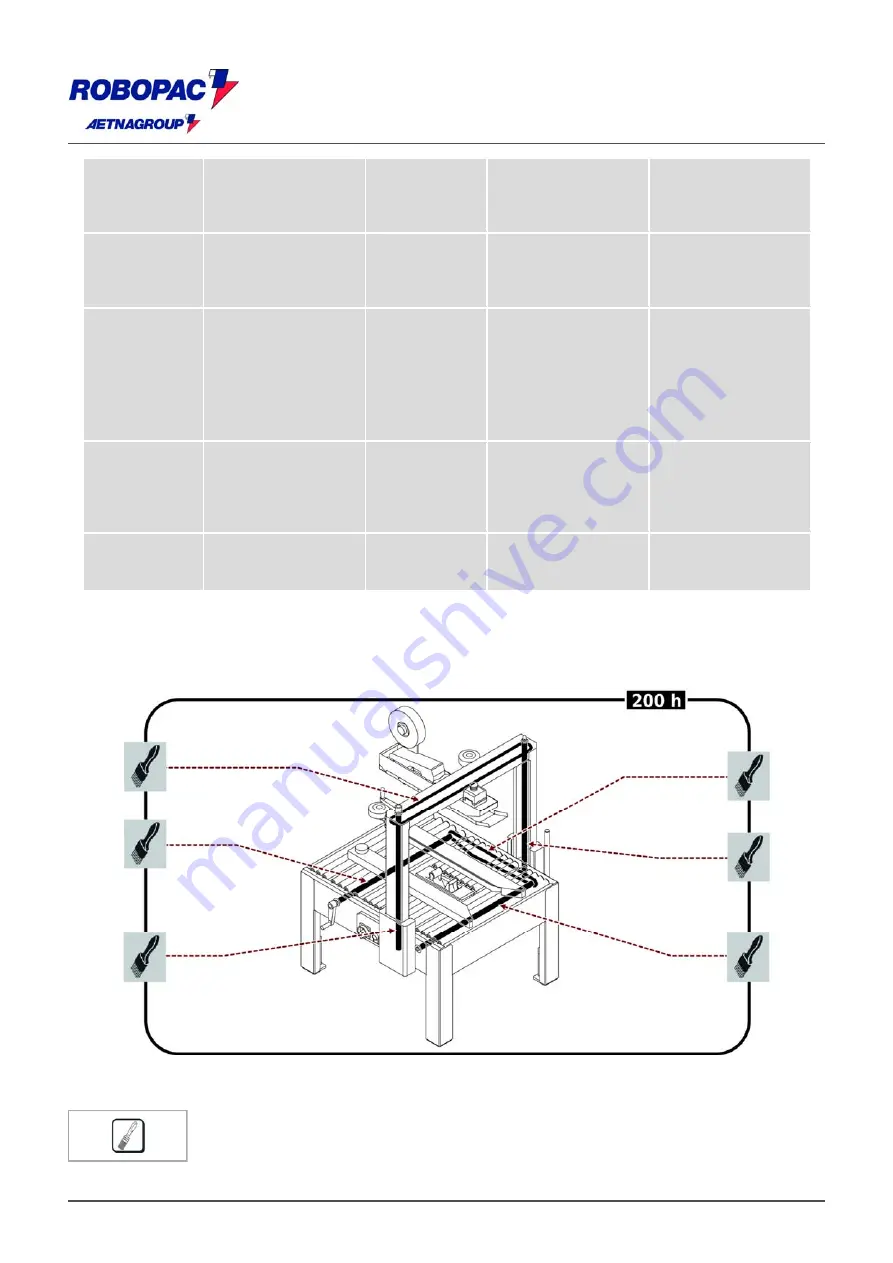

7.3. LUBRICATION POINT DIAGRAM

The following diagram shows the main components and the frequency of the lubrication interventions.

Symbol and Description

Smear with grease

34/43