ROBOTAPE 50 ME - LH

8. TROUBLESHOOTING

8.1. TROUBLES – CAUSES – REMEDIES

The troubleshooting table lists the problems, the possible causes and solutions.

Problem

Cause

Remedy

The box blocks during the

taping operation.

-

Conveying belts worn

out.

-

Incorrect height of top

taping unit.

-

Incorrect conveyor belt

opening.

-

Replace conveying belts.

See “conveyor belt

replacement”.

-

Reposition taping unit.

See “top taping unit

positioning”.

-

Reposition the conveyor

belts.

See "conveyor belt

positioning".

The sealing tape is not

centred on the box.

-

The transmission chain

of the transport unit

moves too slow.

-

The adhesive tape is not

positioned correctly on

the taping unit.

-

Adjust the tension of

the driving chain.

See “how the adjust the

driving chain of the

transport unit”.

-

Place the adhesive tape

correctly on the taping

unit.

See “Tape position

adjustment”.

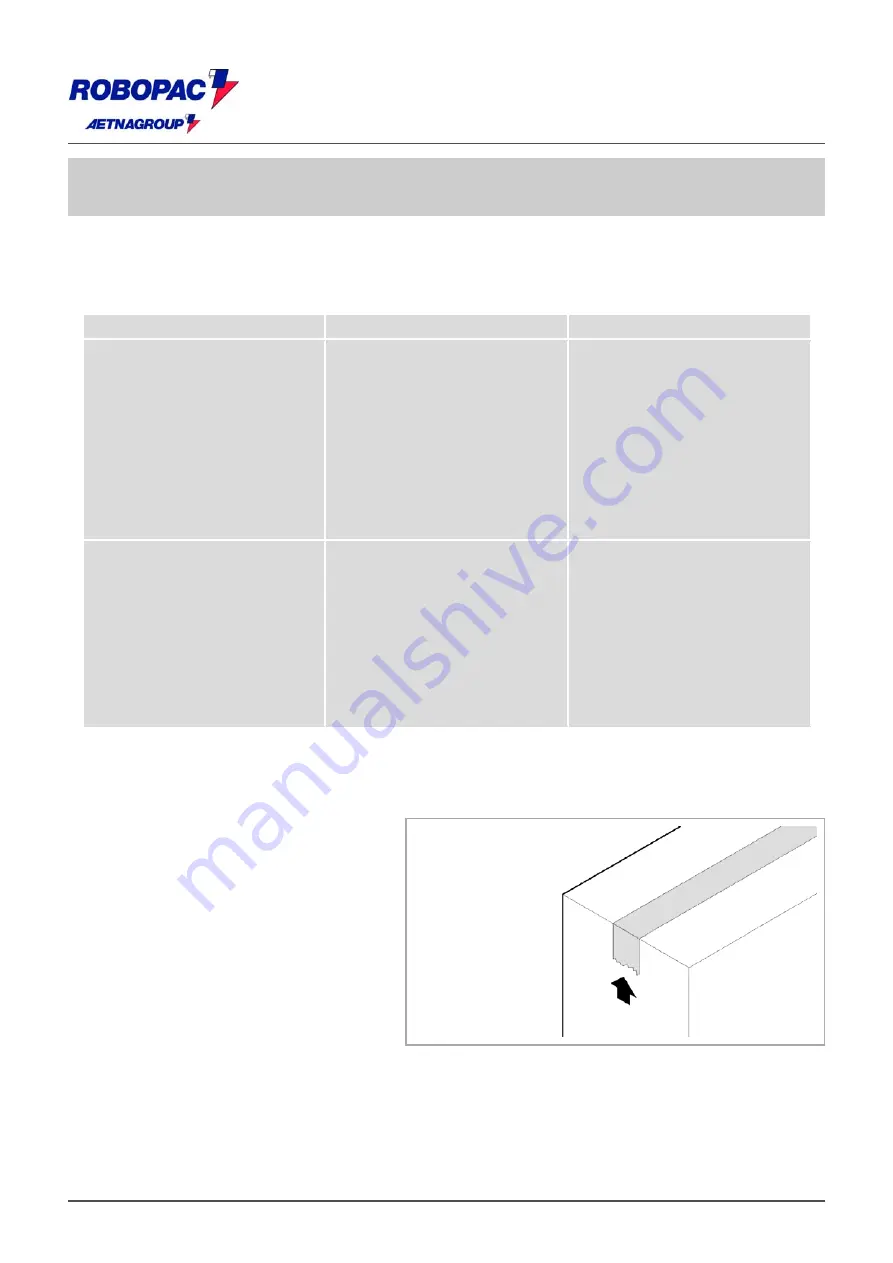

8.2. CORRECTING TAPING ERRORS

Below are a few errors that may occur during normal operation.

Problem

Ragged cut or no cut.

Remedy

Clean or replace the blade.

|

Important

With weak glue tapes it may be necessary to

increase the braking effect on the roll holder

roller and the first transmission roller.

36/43