ROBOTAPE 50 ME - LH

9. SPARE PARTS REPLACEMENT INFORMATION

9.1. RECOMMENDATIONS FOR REPLACING PARTS

‒

Carry out the interventions with all the safety devices enabled and wear the DPI provided.

‒

DO NOT carry out any intervention that is not described in the manual but contact an Assistance Service

authorised by the manufacturer.

‒

DO NOT damp in the environment materials, pollutant liquids and the residues created during the

interventions but dispose them according to the standards in force.

|

Important

Before carrying out any replacement activate all safety devices provided for, and assess if it is necessary to

inform operating personnel and the personnel nearby.

In particular, confine the neighbouring areas to impede access to the devices that could, if activated, produce

unexpected danger conditions provoking hazards to personal safety and health.

When replacing worn parts, use only original replacement parts.

The Manufacturer is not responsible for any damage to property or injuries to people caused by the use of non-

genuine spare parts or which may result from repairs not authorised by the Manufacturer.

When ordering new parts, follow the instructions given in the spares catalogue.

|

Important

Before performing any replacement operation, disconnect the power supply.

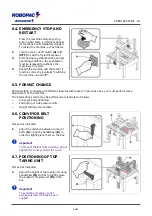

9.2. REPLACEMENT OF CONVEYOR BELT

Proceed as indicated.

1.

Deactivate the main electrical knife to stop the machine under safe conditions.

2.

Remove transmission cover

(A)

.

3.

Loosen nut

(C)

.

4.

Operate the nuts

(B)

to loosen the tape

(D)

completely.

5.

Remove tape

(D)

and replace it.

6.

Adjust belt tension (See “conveyor belt adjustment”).

7.

Repeat the operations described to replace the other belt.

8.

Start conveyor movement to check correct operations.

9.

Re-assemble the casing

(A)

at the end of the operation.

38/43