- 40 -

- 40 -

English

English

Chapter 7

MAINTENANCE INforMATIoN

7.2.

maintenance periOd taBle

important

Keep the machinery in maximum efficiency condition and perform

all the scheduled maintenance operations provided for by the

manufacturer.

proper maintenance will provide the best performance, a longer

life span and constant compliance with safety requirements

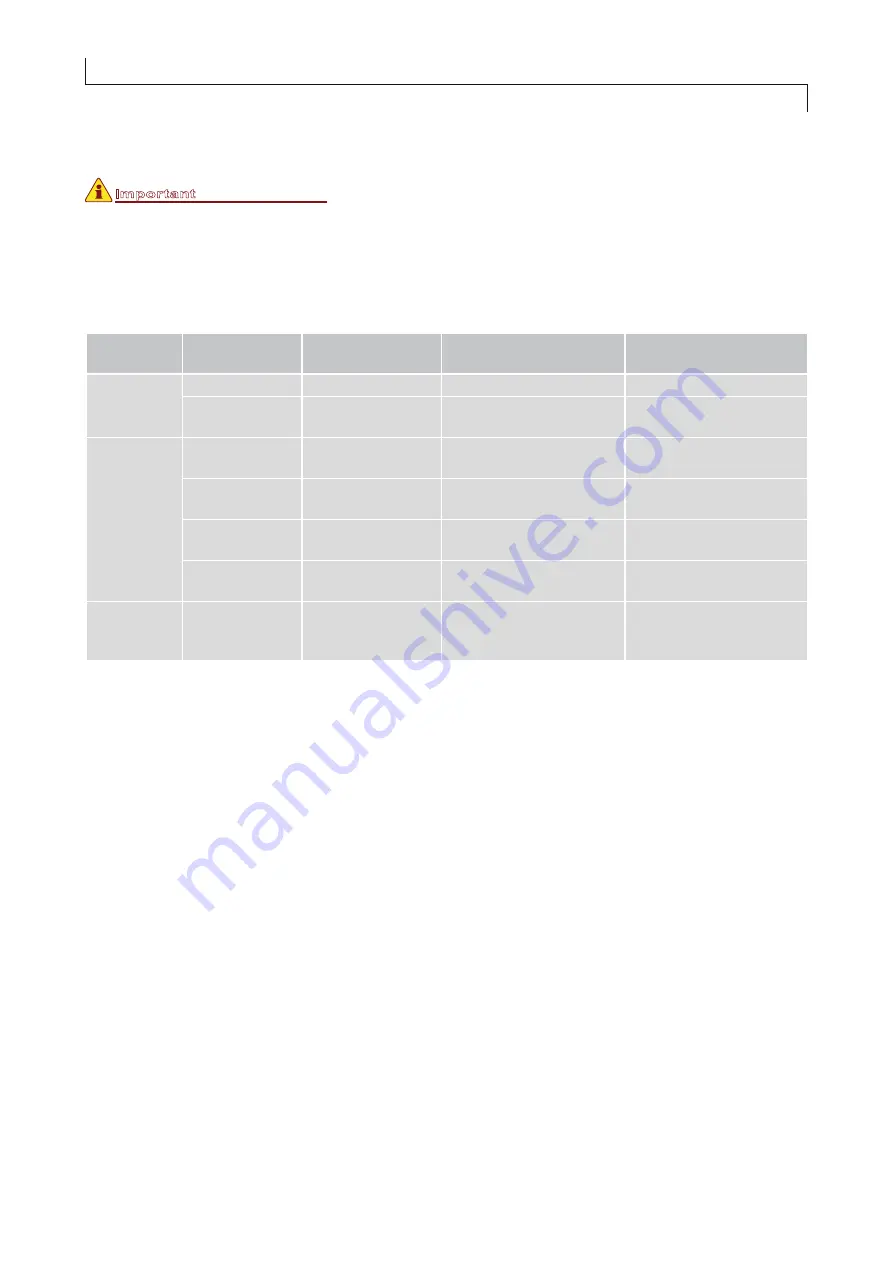

table 7.1.:

Maintenance period

Frequency

Component

Type of

intervention

Procedure

Reference

Every

8 hours

Machine

general inspection Clean with a cloth of air jet

Reducer filter

Condensation

control

Condensation

discharging

.

See 7.5. “Condensate

drainage”

Every

200 hours

Reducer filter

Cleanliness

Clean with a blast of air

and alcohol

See 7.6. “cleaning air filter”

Safety devices

Efficiency control

replace the damaged

components

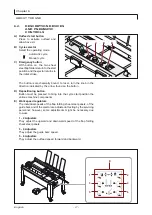

Slide guides

general inspection Cleaning and

lubrication

(*)

See 7.3. “Lubrication point

diagram”

Shifting chains

general inspection Cleaning and

lubrication

(*)

See 7.3. “Lubrication point

diagram”

Every

2000 hours

Chain for moving

the flap-closing

sheets

general inspection Cleaning and

lubrication

(*)

See 7.3. “Lubrication point

diagram”

(*)

Chains and sliding guides can be reached from the bottom part of

the machine.