20 UG 20-UG 25-OI-vers. 3.2 gb. 06.08.14.doc

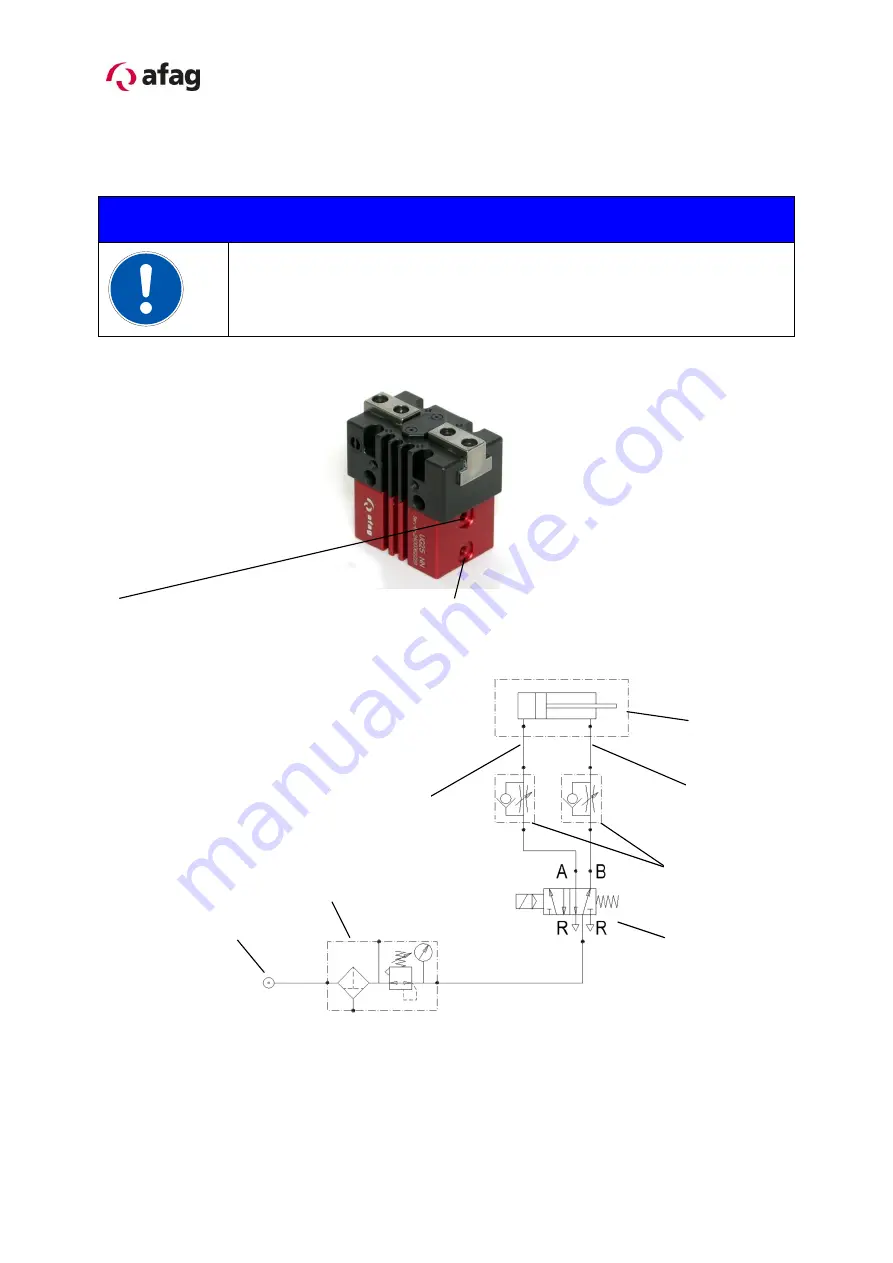

3.2.4 Pneumatic connection for the UG-Universal gripper

NOTE

Minimal compressed air quality according to

ISO 8573-1; 2010 (7-4-4)

P1

“Close” connection

P2

“Open” connection

1

Compressed air connection

4

One-way restrictor

2

Maintenance unit

5

Gripper (UG 20 /UG 25)

3

5-2 port directional control valve

P1/P2

Prise d’air

1

2

4

5

3

P1

P2

Summary of Contents for 50030771

Page 14: ...14 UG 20 UG 25 OI vers 3 2 gb 06 08 14 doc 3 1 8 Dimensions drawing UG 20 ...

Page 15: ...UG 20 UG 25 OI vers 3 2 gb 06 08 14 doc 15 3 1 9 Technical data of the UG 20 ...

Page 16: ...16 UG 20 UG 25 OI vers 3 2 gb 06 08 14 doc 3 2 0 Preferred combinations UG 20 ...

Page 17: ...UG 20 UG 25 OI vers 3 2 gb 06 08 14 doc 17 3 2 1 Dimensions drawing UG 25 ...

Page 18: ...18 UG 20 UG 25 OI vers 3 2 gb 06 08 14 doc 3 2 2 Technical data of the UG 25 ...

Page 19: ...UG 20 UG 25 OI vers 3 2 gb 06 08 14 doc 19 3 2 3 Preferred combinations UG 25 ...