Page 16

2/20/2019

R01.0

The belt tension and center run on the drive and guide roller has been pre-set at the

factory.

The belt tension must be set so that even if the parts storage container is full (observe

the max. belt capacity of your belt hopper type!) the conveyor belt does not have a gap.

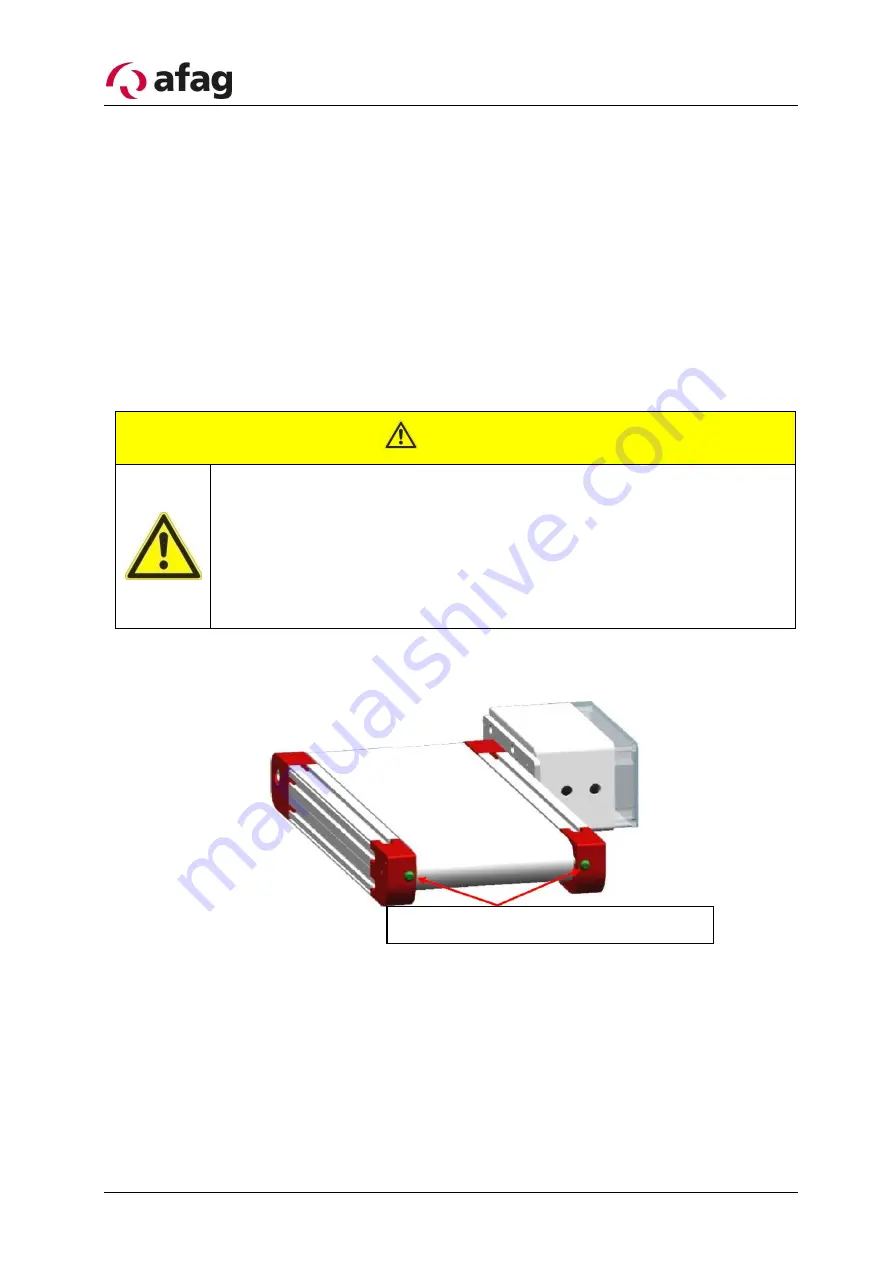

The belt tension is adjusted by turning the round-head screws on the tensioning revers-

ing heads. Rotating in clockwise direction increases the belt tension. At the same time,

this adjustment can also influence the center run of the belt. The conveyor belt must run

centered between the head pieces. If the belt abuts too much on one of the head pieces,

the center run must be corrected to prevent increased wear to the belt. To do so, tighten

the round-head screw on the tensioning reversing head that the belt runs on or loosen

the screw on the opposite tensioning reversing head. Observe the belt tension in the

process!

CAUTION

Tightening the belt too much may overload the belt, the bearings

and also the motor. After making fine adjustments, check the mo-

tor’s current consumption. If it exceeds the rated data on the name-

plate, the round-head screws must be evenly loosened. After mak-

ing the adjustment, perform a test run for several hours. After initial

commissioning, check several times a day to ensure that the belt

is running centered.

Clamping screws on clamping reversing head

Summary of Contents for 50494738

Page 22: ...Page 22 2 20 2019 R01 0 ...