Commissioning

98 – 112

Assembly instructions EN

EPS Handling systems

Date 08.09.2021

Version 2.0

B) Setting the reference point

Setting the reference point is necessary to prevent an index from being detected

too early or too late when referencing the axis. This would result in a position

shift according to the pole division of the band.

To set the reference point, the distance between the mechanical stop and the

index on the magnetic tape must be set to the distance according to the following

table:

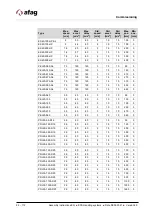

Sensor type Distance to be

set

Distance min. Distance max. Pole division

band

MSK1000

0.50mm

0.35mm

0.65

1mm

To set the distance between the mechanical stop and the index on the magnetic

tape, proceed as follows:

1. Configure the system as described in the LinMot manual.

- Set the Home Position to 0 mm.

2. Reference the axis.

3. De-energise the axis by removing the switch ON-bit.

4. Press the axle by hand against the mechanical stop.

5. Adjust the actual position by moving the sensor so that the distance to be

set appears with a negative sign.

- e.g. Home Position = 0 mm -> Actual Position = - 0.5 mm

If the home position is set to a different value, the corresponding offset must

be taken into account for all masses:

•

e.g. Home Position = 50 mm -> Actual Position = 49.5 mm

If the axis is set to positive Homeing, the distance must be added:

•

e.g. Home Position = 500 mm -> Actual Position = 500.5 mm

6. Set new axis reference position.

7. Move the axle to the mechanical end stop so that the current is at maximum.

8. Check setting (e.g. -0.5 mm)

The desired distance is set.

C) Switching distance

The reference sensor of the electrical axes is mounted with a feeler gauge at

a distance of 0.1 mm parallel to the switching lug.