R05.0

16/05/2019

Page 11

3

Assembly instructions

3.1

Transport

WARNING

Improper use of transport means (industrial trucks, cranes, tech-

nical aids, sling gear etc.) may lead to bruises and other injuries.

Required behaviour:

▪

Observe and follow the transport and maintenance instruc-

tions

▪

Proper use of transport means

CAUTION

During transport, the linear feeder must only be held by the base.

The linear track is no lifting point.

3.2

Installing the unit

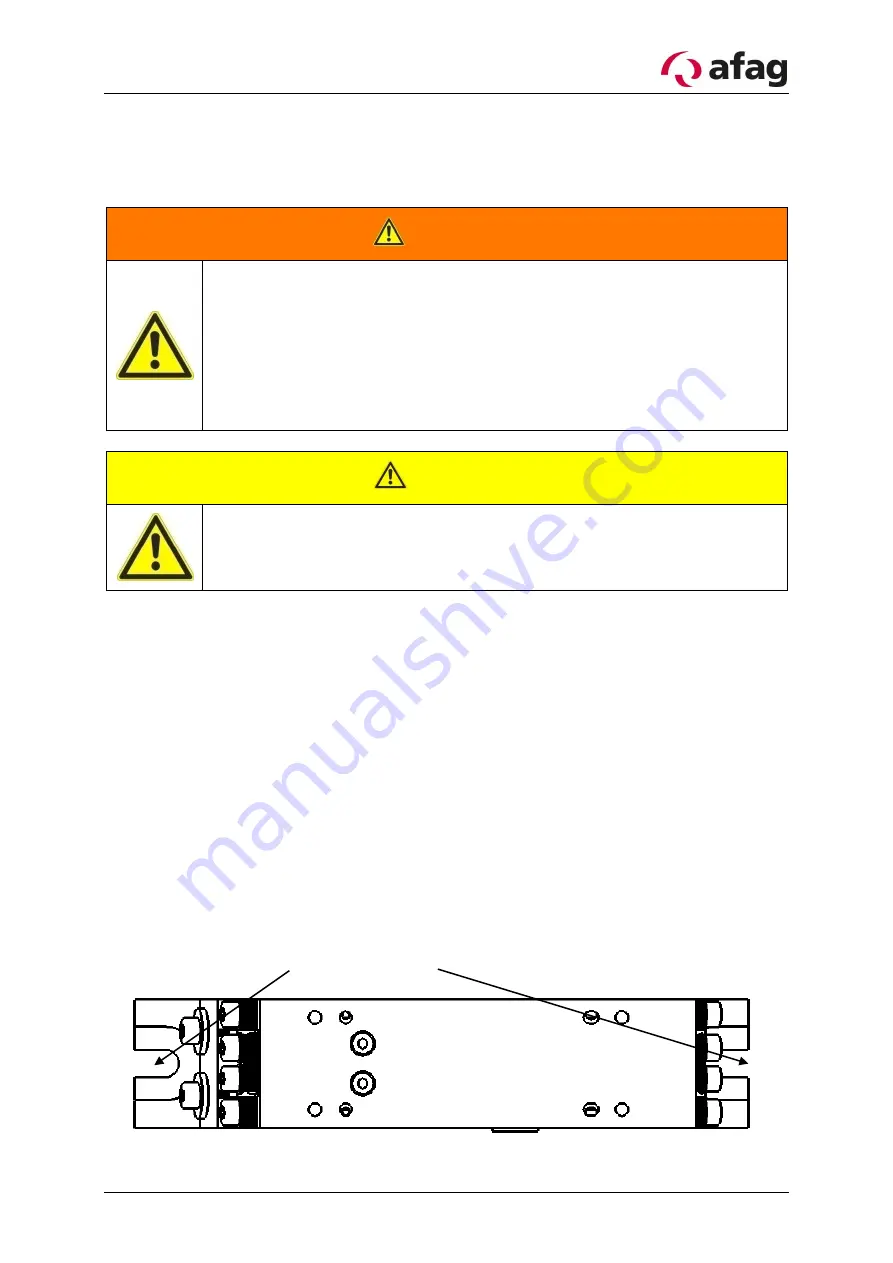

The HLF-M is firmly screwed to the foundation structure by means of slots provided in

the base plate (see Figure 2). This precisely defines the interfaces where the feeder

track enters and exits as well as allowing adjustment. The substructure should be non-

oscillating in a horizontal plane in order to be able to take up any residual forces. Self-

supporting profile constructions have to be reinforced with a base plate to which the Lin-

ear Feeder is attached. A steel plate of at least 20mm thickness and a width of over

120mm should be used for this purpose. The vertical oscillating forces responsible for

energy induction in the foundation structure should be virtually completely eliminated by

a careful balance of weights (see chapter 4.2 Balance of weights). Height adjustments

can be achieved by means of appropriate substructures. Standard Afag components are

available for setting up complete units.

Figure 2:

Attachment slots in the base plate

slots for attaching the HLF-M