R05.0

16/05/2019

Page 15

4

Operating instructions

The first step in adjusting the linear feeders is always to balance the masses and then to

adjust the natural frequency.

4.1

Feeder track design

The linear tracks must be unyielding so that the transport pulses generated by the unit

are fully transferred to the work pieces and no superimposed natural vibration can ad-

versely affect the transport process. This requirement has priority over mass reduction

measures. The preferred material for linear tracks is tool steel (e.g. 1.2842, 90MnCrV8).

Linear track design should adhere to the useful masses specified in chapter 2 Table 1:

Technical data and Table 4: Obligatory values for the working weight

The following size ratio should be aimed for with regard to the feeder track cross-section:

𝐻𝑒𝑖𝑔ℎ𝑡

𝐵𝑟𝑒𝑎𝑑𝑡ℎ

=

2

1

The recommended dimensions are listed in Table 3:

. The di-

mensions are for one vibrating section and can be applied to each of the two vibrating

sections.

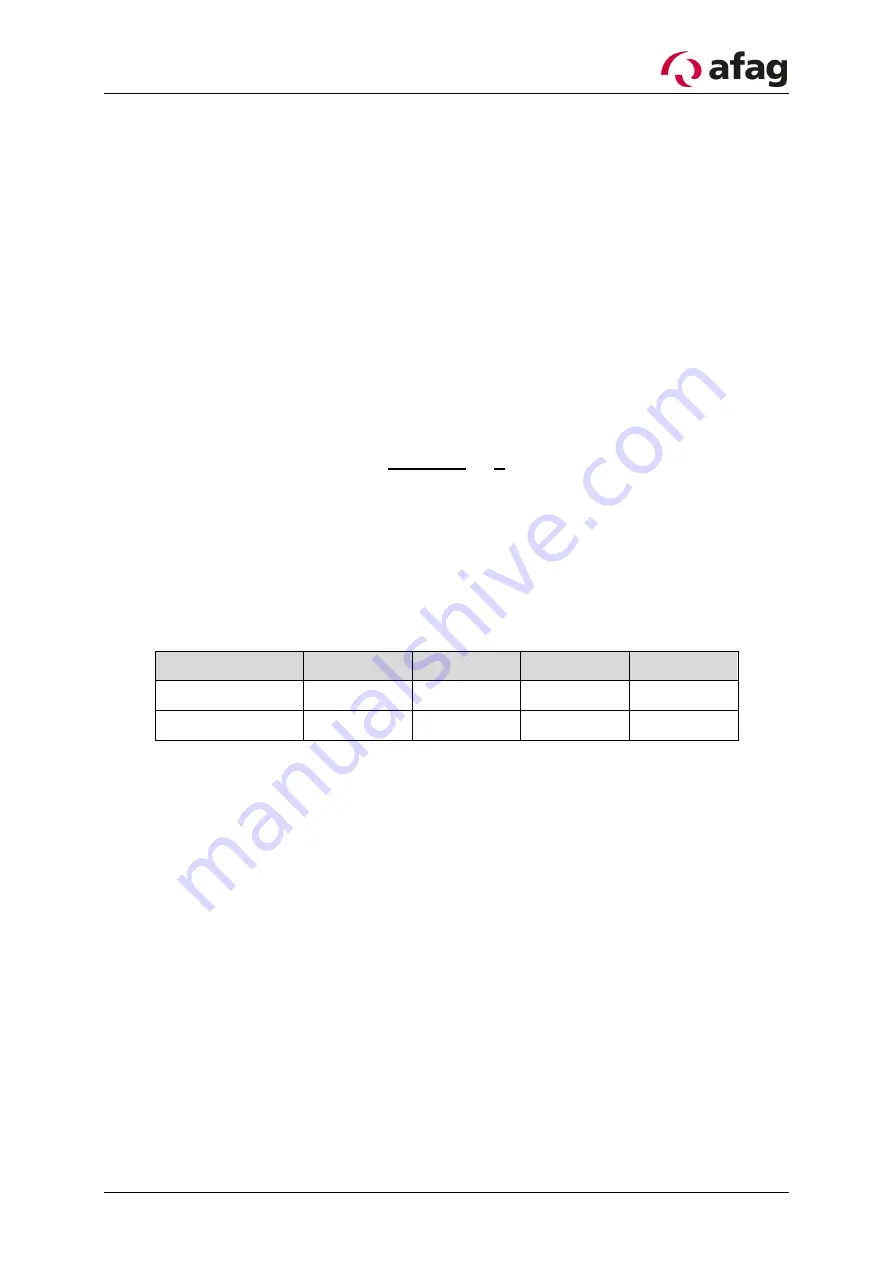

Table 3:

Linear track dimensions

HLF07

HLF12

HLF25

HLF50

Length [mm]

400

500

600

800

Breath [mm]

17

17

24

24

4.2

Balance of weights

The oscillating forces in the base plate of the Afag Linear Feeder are compensated al-

most completely due to the principle of opposing oscillations (push-pull). This balance of

oscillating forces is however only achieved if:

1.

The working weight and the counterweight are balanced as closely as possible.This

means that the working weight and the counterweight are equal. The working weights

specified for respective sizes are listed in Table 4 below. The working weight is the total

weight of all components attached to the mounting plate including the side plate. The

balance of weight is verified by simply weighing the working weight.

2.

The centre of gravity of the working weight is located in the range represented in Fig-

Both conditions have to be taken into consideration at the construction stage of the feed-

er track. An optimal balance of weight is achieved when almost no residual vibrations

can be detected in the substructure.