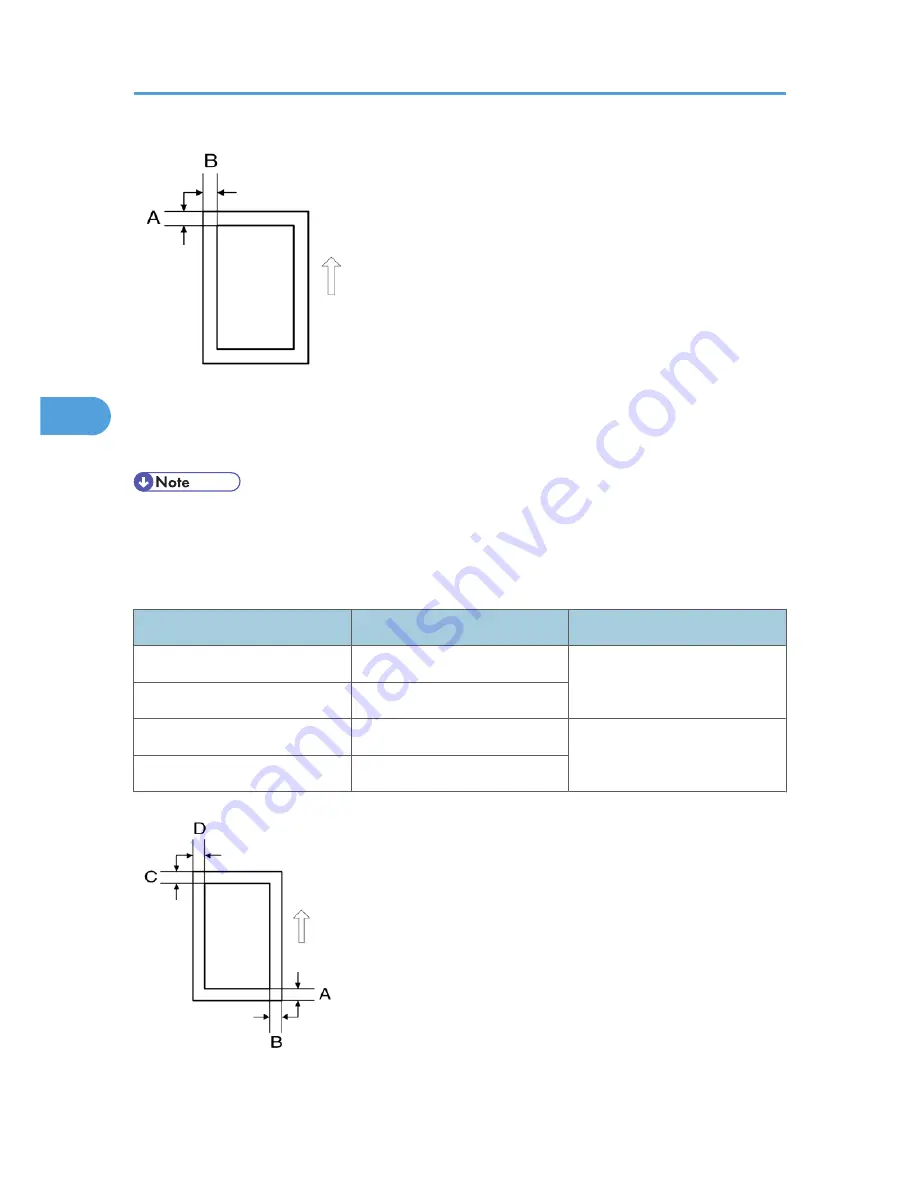

A: Leading Edge Registration

B: Side-to-side Registration

- Blank Margin -

• If the leading edge or side-to-side registration cannot be adjusted to within the specification, then

adjust the leading-edge blank margin or the left-side blank margin.

1. Check the trailing edge and right side edge blank margins, and adjust them using the following SP

modes.

SP mode

Specification

Trailing edge

SP 2101 2

2 +2.5/–1.5 mm

Right edge

SP 2101 4

Leading edge

SP 2101 1

2 ± 1.5 mm

Left edge

SP 2101 3

4. Replacement and Adjustment

96

4

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Summary of Contents for MP1900

Page 2: ...CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...

Page 12: ...10 CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...

Page 128: ...6 Troubleshooting 126 6 CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...

Page 134: ...CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...

Page 136: ...2 CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...

Page 148: ...1 Appendix Specifications 14 1 CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...

Page 152: ...2 Appendix Preventive Maintenance 18 2 CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...

Page 162: ...3 Appendix Troubleshooting Guide 28 3 CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...

Page 188: ...4 Appendix SP Mode Tables 54 4 CÓPIA NÃO CONTROLADA CÓPIA NÃO CONTROLADA ...