6

INSTALLATION INSTRUCTIONS

IDEAA

®

Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specifications are subject to change without notice.

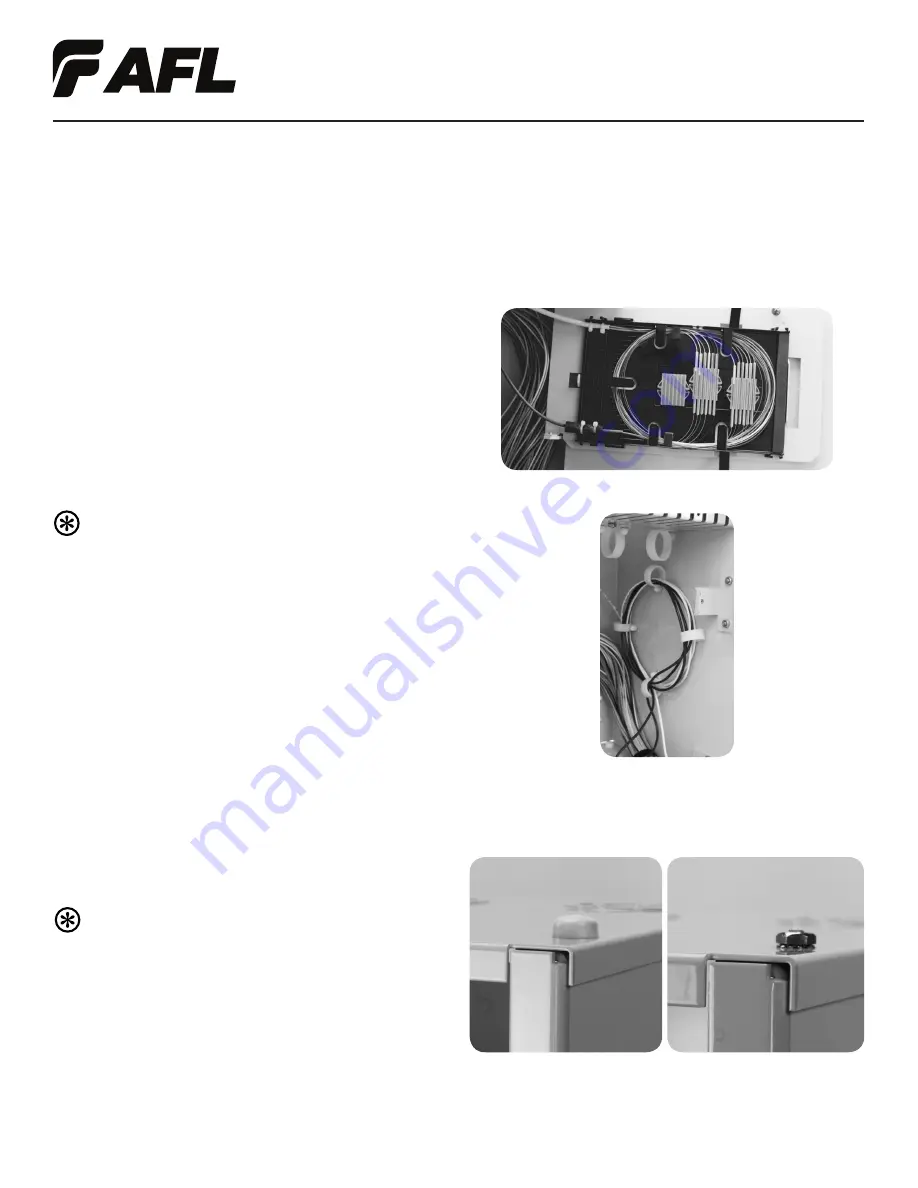

SPLICING

1. Prior to splicing, ensure that adequate slack for both

the feeder fiber and the input pigtail fiber is stored

within the splice tray. Mark fibers for splicing.

2. Clean the individual fiber per accepted local practice

using an approved fiber cleaner.

3. Follow accepted local practice for preparing and

splicing feeder fibers and input pigtail fibers.

4. Once all splicing is complete, route the exposed fibers

inside the splice tray.

(Figure 8)

Note: Thick foam pads may be used to help

organize loose tube bare fibers within the

splice tray.

5. Replace the splice tray cover.

6. Secure the splice tray to the swing down splice tray

holder with the hook and loop band.

7. The fiber management rings on the side wall of the IDC

may be used for slack storage.

(Figure 9)

8. Return the swing down splice tray holder to the upright

position and secure the shipping screw.

DISTRIBUTION CABLE INSTALLATION - MPO DISTRIBUTION CABLE

The top plate of the 144F IDC may be removed to aid in

the distribution cable installation process.

Note: For distribution cable entry from the bottom

of the cabinet, reference the Cable Installation

section of this document before continuing on

to Step 7.

1. Remove the five caps to expose the nuts on the top

of the 144F IDC.

2. Using a standard 216 style tool, or similar, remove the

five nuts that secure the top plate to the cabinet body.

(Figure 10)

DISASSEMBLE COMPRESSION FITTING – CABLE REPLACEMENT

1. To disassemble for cable replacement, loosen the sealing nut.

2. Grip the disconnected cable and pull while turning the cable in the counter-clockwise direction.

Figure 8

Figure 9

Figure 10