Software 83

4510001 REV B - 220620

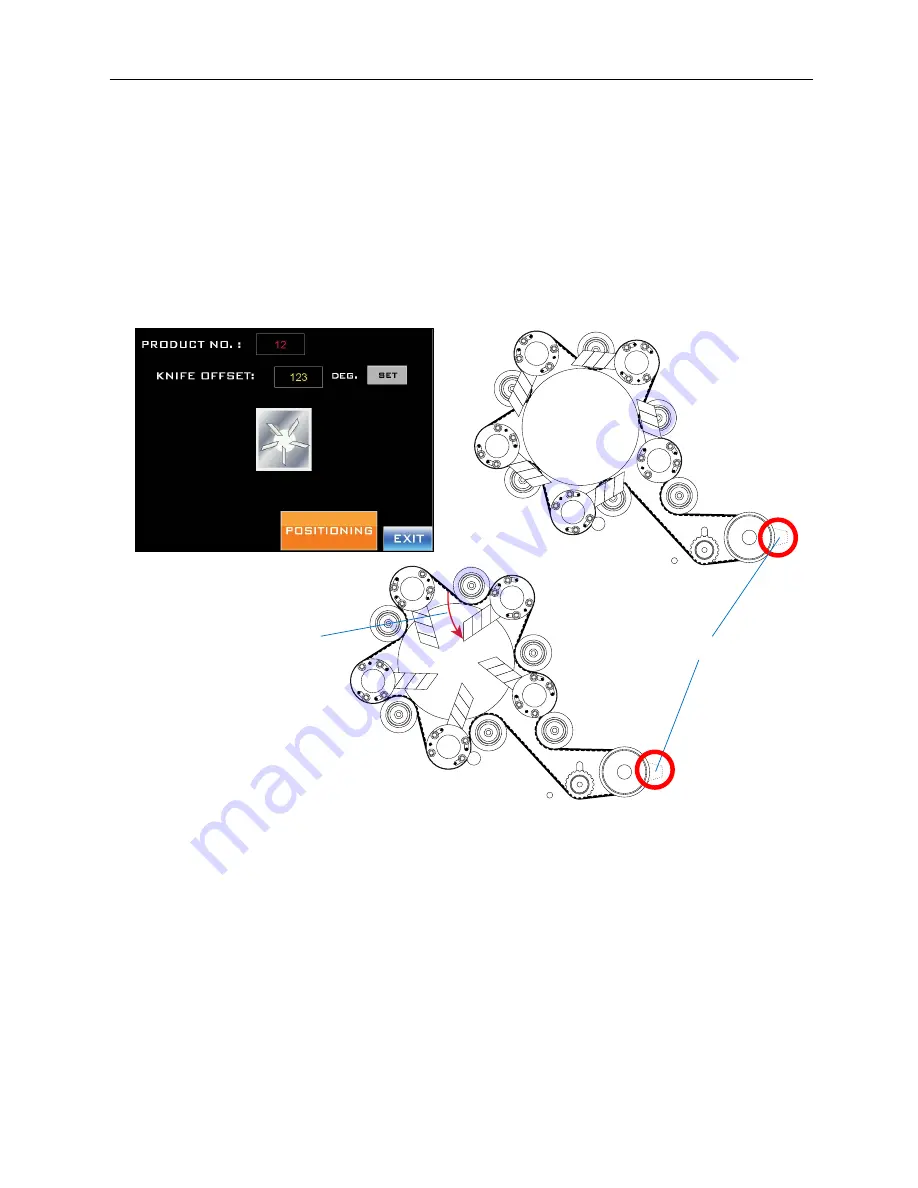

Knife Offset Screen

Accessed from the

Other Screen

.

This Screen relates to the Cutter Blades, enabling the user to input an offset angle relative

to the Cutter Home Tab.

When the Cutter Blades are in the home position, they are at a certain angle in relation to

the Cutter Home Tab, which always must be directly beneath the Cutter Home Position

Sensor. If the Cutter Blades have just been replaced, they may not be aligned at the same

angle to the Cutter Home Tab. The

Knife Offset Screen

allows this to be corrected.

“Knife Offset” Field:

Enters an angle to recalibrate the home position for the blades relative to the Cutter

Home Tab. In the example above, Position A (above) shows the Blades in their correct

home position relative to the Cutter Home Tab. In Position B, the Blades are 40° out of

alignment from their home position. By entering “40” in the Knife Offset Field, pressing

the “Set” Button, and pressing and holding the “Positioning” Button, the Cutter Blades

realign to their correct home position relative to the Cutter Home Tab (Position A).

“Set” Button:

Accepts the value entered into the “Knife Offset” Field.

“Positioning” Button:

Moves the Cutter Blades to the angle entered into the “Knife Offset” Field.

Cutter Home Tab

Position A

Position B

40°

Summary of Contents for LX-150

Page 1: ...LX 150 Shrink Sleeve Label Applicator User Guide ...

Page 2: ...2 Abbreviations 4510001 REV B 220620 ...

Page 4: ...4 Abbreviations 4510001 REV B 220620 ...

Page 12: ...12 Abbreviations 4510001 REV B 220620 ...

Page 76: ...76 Installation 4510001 REV B 220620 ...

Page 132: ...132 Setup 4510001 REV B 220620 ...

Page 146: ...146 Operation 4510001 REV B 220620 ...

Page 186: ...186 Electrical Schematics 4510001 REV B 220620 LX150N J002 220V Indicator Lamp Circuit ...

Page 187: ...Electrical Schematics 187 4510001 REV B 220620 LX150N J003 220V PLC ...

Page 189: ...Electrical Schematics 189 4510001 REV B 220620 LX150N J005 220V ...

Page 190: ...190 Electrical Schematics 4510001 REV B 220620 LX150N J006 220V ...

Page 191: ...Electrical Schematics 191 4510001 REV B 220620 LX150N J007 220V HMI ...

Page 192: ...192 Electrical Schematics 4510001 REV B 220620 LX150N J008 220V UR1 Unwind Circuit ...

Page 193: ...Electrical Schematics 193 4510001 REV B 220620 LX150N J009 220V UR1 Unwind Cable ...

Page 194: ...194 Electrical Schematics 4510001 REV B 220620 LX150N J010 220V Film Roll Motor ...

Page 195: ...Electrical Schematics 195 4510001 REV B 220620 LX150N J011 220V Timing Screw Motor Drive ...

Page 196: ...196 Electrical Schematics 4510001 REV B 220620 LX150N J012 220V Timing Screw Motor ...

Page 197: ...Electrical Schematics 197 4510001 REV B 220620 LX150N J013 220V Brushdown Circuit ...

Page 200: ...200 Electrical Schematics 4510001 REV B 220620 LX150N J016 220V PLC I O Extension ...

Page 202: ...202 Electrical Schematics 4510001 REV B 220620 LX150N J002 480V Indicator Lamp Circuit ...

Page 203: ...Electrical Schematics 203 4510001 REV B 220620 LX150N J003 480V PLC ...

Page 205: ...Electrical Schematics 205 4510001 REV B 220620 LX150N J005 480V ...

Page 206: ...206 Electrical Schematics 4510001 REV B 220620 LX150N J006 480V ...

Page 207: ...Electrical Schematics 207 4510001 REV B 220620 LX150N J007 480V HMI ...

Page 208: ...208 Electrical Schematics 4510001 REV B 220620 LX150N J008 480V UR1 Unwind Circuit ...

Page 209: ...Electrical Schematics 209 4510001 REV B 220620 LX150N J009 480V UR1 Unwind Cable ...

Page 210: ...210 Electrical Schematics 4510001 REV B 220620 LX150N J010 480V Film Roll Motor ...

Page 211: ...Electrical Schematics 211 4510001 REV B 220620 LX150N J011 480V Timing Screw Motor Drive ...

Page 212: ...212 Electrical Schematics 4510001 REV B 220620 LX150N J012 480V Timing Screw Motor ...

Page 213: ...Electrical Schematics 213 4510001 REV B 220620 LX150N J013 480V Brushdown Circuit ...

Page 216: ...216 Electrical Schematics 4510001 REV B 220620 LX150N J016 480V PLC I O Extension ...

Page 219: ...Diagrams and Parts Lists 219 4510001 REV B 220620 Dancer Assembly ...

Page 221: ...Diagrams and Parts Lists 221 4510001 REV B 220620 Cutter Assembly ...

Page 225: ...Diagrams and Parts Lists 225 4510001 REV B 220620 Applicator Assembly ...

Page 227: ...Diagrams and Parts Lists 227 4510001 REV B 220620 LX 150 Frame ...

Page 229: ...Diagrams and Parts Lists 229 4510001 REV B 220620 Head Height Adjust ...

Page 235: ...Diagrams and Parts Lists 235 4510001 REV B 220620 Support and Film Drive Wheel Assemblies ...

Page 238: ...238 Diagrams and Parts Lists 4510001 REV B 220620 400mm Timing Screw Assembly ...

Page 240: ...240 Diagrams and Parts Lists 4510001 REV B 220620 ...