Product description

– English –

FloCo-Top-2

24

3

Product description

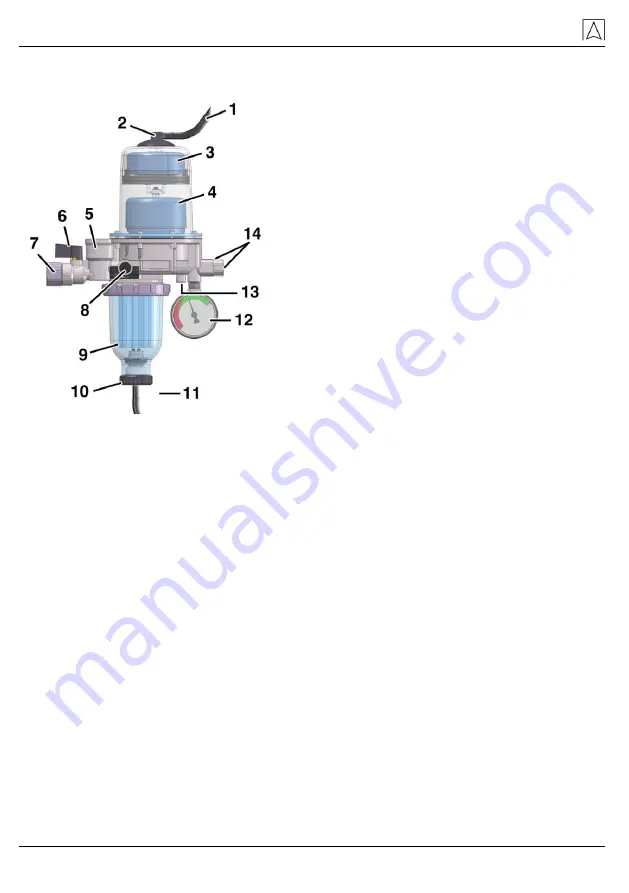

1

Vent hose (optional)

2

Connection for vent hose

3

Upper float chamber

4

Lower float chamber

5

Overpressure device with integrated check

valve

6

Shut-off valve for shutting off the suction line

7

Tank connection

8

Changeover valve for single/multiple filtra-

tion

9

Filter cup with filter insert

10

Drain valve

11

Drain hose

12

Pressure gauge

13

Bypass valve

14

Flow / return (connection from/to burner)

Fig. 18: FloCo-Top-2

Single/multiple filtration

Modern burners use approx. 10-30 % of the fuel oil supplied. The

excess oil is returned to the fuel oil de-aerator and then supplied to

the flow. In the case of FloCo-Top-2, the oil is guided to the change-

over valve via the float chamber and can then be added directly to

the supply or it can be filtered again by switching the valve.

With an Opticlean filter insert, 50 % of the particles in the circulated

oil are removed with a filter rating of 5

μ

m per filtration. A second fil-

tration removes another 50 % of the remaining particles 5-20 µm so

that a total of 75 % of all particles are removed. After the third filtra-

tion, the rate increases to 87.5 %, after the fourth to 93.8 %, etc. This

means that several filtration processes result in a genuine 5

μ

m filtra-

tion. The quality of the fuel oil continuously improves and contributes

to improved combustion processes and optimum calorific values.

So far, it was almost impossible to avoid air accumulations caused

by the low flow rate through the filter insert. Switching to multiple fil-

tration removes this problem. The fuel oil added from the return in-

creases the flow rate since it is not burner consumption, but the

pump circulation volume (as in a dual-line filter) that flows through