– English –

Technical specifications

FloCo-Top-2

27

FloCo-Top-2KM Optimum Si:

Like FloCo-Top-2KM Si, but with long

filter cup and long sintered plastic filter.

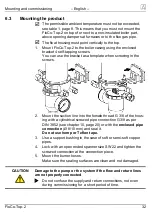

3.2

Function

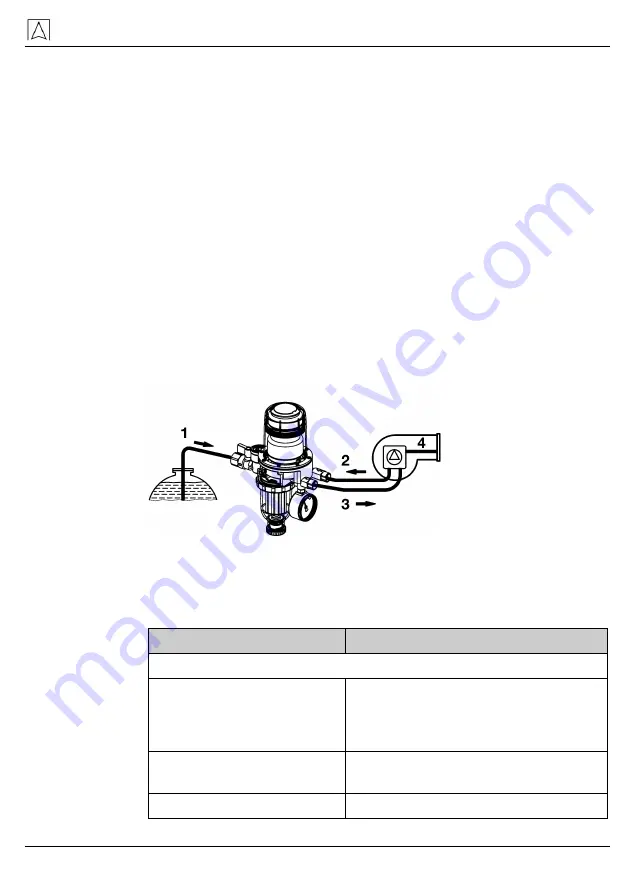

The burner pump draws the fuel oil from the tank via the filter and the

check valve installed in the housing and delivers it to the nozzle. The

excess oil (i.e. the oil exceeding the nozzle capacity) is pumped via

the connection piece of the return line into the float chamber. While

the liquid level gradually increases in the float chamber, the oil is de-

aerated by the de-aeration valve.

When the oil reaches a level of approx. 20-30 mm above the bottom,

the floats begin to operate and actuate the bypass valve, thus deliv-

ering the de-aerated return oil to the suction pipe. This way, the sys-

tem only withdraws the amount of oil from the tank via the filter which

is actually needed for combustion.

The major part of the volume flow to the tank consists of de-aerated

fuel oil and a small portion of fuel oil from the tank which may still

contain air.

1

Q

Tank

= Q

Nozzle

2

Q

Return

3

Q

Flow

4

Q

Nozzle

Fig. 27: Function

4

Technical specifications

Table 4: Technical specifications

Parameter

Value

General specifications

Dimensions (W x H x D)

183 x 308 x 103 mm (type: MM)

183 x 254 x 103 mm (type: KM)

183 x 348 x 103 mm (type: Optimum)

Burner connection

G 3/8 male with 60° cone for burner

hose

Tank connection

G 3/8 female at shut-off valve