Operation

– English –

FloCo-Top-2

36

7

Operation

7.1

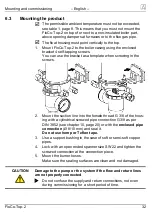

Oil level in the float housing

The oil level depends on the operating conditions of the facility and

amounts to approx. 20-50 mm in suction mode. If the oil level is

higher, the float housing may be completely filled with oil if the suc-

tion line is tight. This is caused by the absorption of the air through

the fuel oil. Over time, this results in a reduction of the air cushion.

When the operating conditions change (e.g. decreasing oil level in

the tank), the air cushion is formed again in the float housing.

7.2

Pressure mode

Since in pressure mode with an oil pump there is no gas formation

caused by suction, it is not meaningful to use FloCo-Top-2 KM in this

mode. In pressure mode, it is recommended to use a single-line filter

with return pipe connection. If the system requires a oil de-aerator,

you can use a FloCo-TOP-2MM with retrofitted brass filter cup or re-

placeable filter cartridge, see chapter 10, page 20.

In the case of such applications, take appropriate measures to

prevent the maximum permissible inlet pressure of 0.7 bar from

being exceeded even in the case of error conditions (defective

pressure reducer, etc.), e.g. by means of a bypass valve, a

pressure switch, etc.

A drip pan has to be placed below the burner hoses and the oil

de-aerator.

7.3

Use in flood hazard areas

FloCo-Top-2 is suitable for flood hazard areas. FloCo-Top-2 is water-

tight up to 10 m water column (1 bar pressure).

After a flood, FloCo-Top-2 must be replaced.

Check FloCo-Top-2 for proper function.