Troubleshooting

– English –

FloCo-Top-2

38

8.2

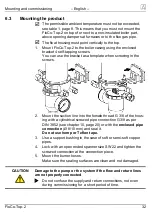

Replacing the burner hoses

Prior to replacing the burner hoses, you can completely drain the re-

turn line and the float chamber.

1.

In addition to draining the filter cup as described above, open

the bypass valve with a hex key, spanner size SW 3.

The oil is drained via the float chamber into the filter cup and via

the drain valve.

2.

Replace the burner hoses.

3.

Close the bypass valve and the drain valve.

9

Troubleshooting

Repairs may only be performed by specially trained, qualified staff.

Table 6: Troubleshooting

Problem

Possible reason

Repair

Heavy oil foam in

the float chamber

due to excessive

amounts of air

sucked in (in excess

of the possible sep-

aration capacity of

> 4 l/h).

Suction line not tight

Perform a tightness test of

the suction line (vacuum test

or pressure test).

Screw connections at the

suction side not tight

Seal the screw connections

Initial commissioning with-

out separate suction pump

Use suction pump

Suction line rating too great

Observe DIN 4755-2: Flow

rate 0.2-0.5 m/s

Burner switches off

at irregular intervals

due to malfunctions

Air accumulations in the

suction line because pipe

cross section is too great.

When the anti-siphon valve

opens after the pre-

aeration time of the burner,

a greater bubble may pass

through which causes the

burner to switch off.