10

Mounting

EN

Fuel oil filters

5

Mounting

5.1

Preparing mounting of R 500

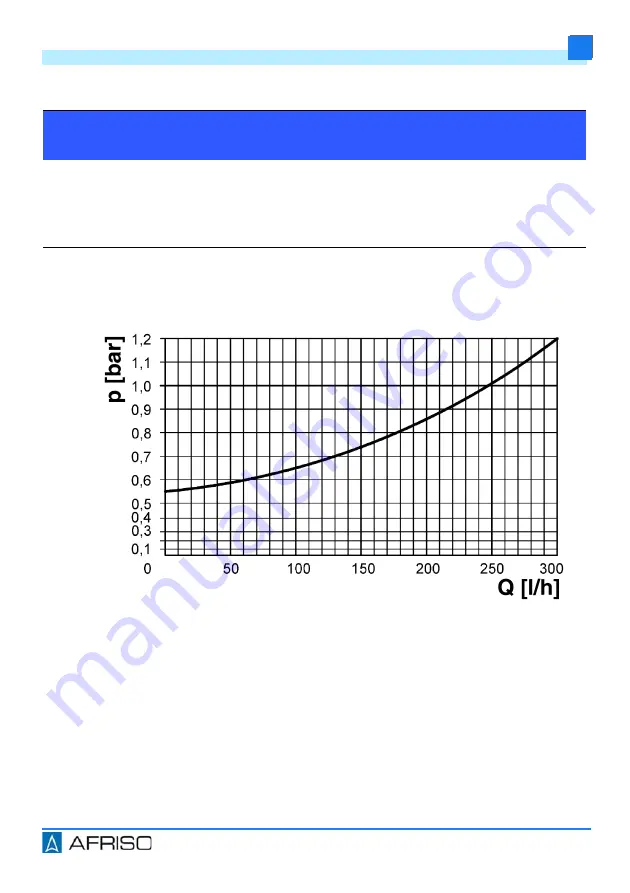

Verify that the burner pump has a sufficient pressure resistance at the

return end (see "Return pressure").

The maximum return flow corresponds to the pump capacity since the entire

volume flow is pumped into the return line during the pre-aeration time. Any

static inlet pressure of the oil column is added to the maximum return pres-

sure.

If the pressure resistance is not sufficient at the return side of the burner

pump, it is recommended to use the automatic fuel oil de-aerator Flow-Con-

trol or the filter de-aerator FloCo-Top.

NOTICE

ESCAPING OIL DURING FILTER REPLACEMENT

•

Verify that the pressure supply system is disconnected from mains.

•

Discharge any inlet pressure.

Failure to follow these instructions can result in equipment damage.

Fig. 5: Return pressure

Summary of Contents for 20281

Page 7: ...7 Produktbeschreibung DE Heizölfilter Abbildung 2 Typ R 500 Abbildung 3 Typ Z 500 Z 500 ...

Page 17: ...17 Wartung DE Heizölfilter 8 2 Filtereinsatz tauschen 8 2 1 Filtereinsatz ausbauen B C ...

Page 18: ...18 Wartung DE Heizölfilter ...

Page 19: ...19 Wartung DE Heizölfilter 8 2 2 Filtereinsatz einbauen ...

Page 31: ...7 Product description EN Fuel oil filters Fig 2 Type R 500 Fig 3 Type Z 500 Z 500 ...

Page 42: ...18 Maintenance EN Fuel oil filters ...

Page 43: ...19 Maintenance EN Fuel oil filters 8 2 2 Mounting the filter insert ...

Page 55: ...7 Description du produit FR Filtre fuel Figure 2 Type R 500 Figure 3 Type Z 500 Z 500 ...

Page 66: ...18 Maintenance FR Filtre fuel ...

Page 67: ...19 Maintenance FR Filtre fuel 8 2 2 Montage d élément filtrant ...