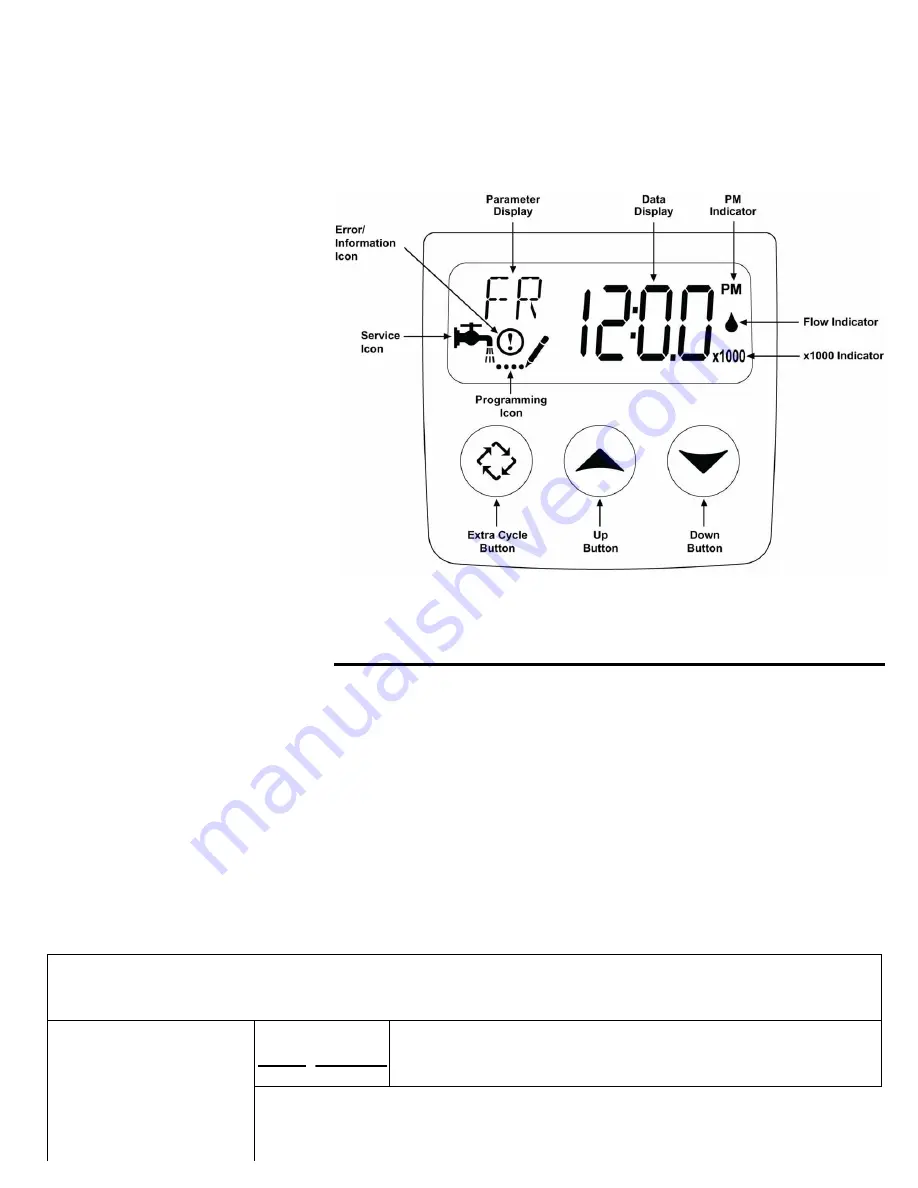

Img 11 - SXT Controls

If you have the mechanical valve skip the digital controller sections and

proceed with the mechanical setup

For initial programming

enter master programming

by setting the clock to 12:01

pm. To set the time of day

press and hold the up OR

down arrow until the

service icon is replaced with

the programming icon. Use

the up and down arrows to

set the time of day (PM is

indicated in the upper right

corner of the screen). Hold

the arrow button to

advance quickly through

the time. Once the time is

set, press the extra cycle

button to save the setting.

Once the parameter display

is gone, press and hold the

up AND down arrow

buttons together for 5-10

seconds until the

programming icon appears and [DF] is shown in the parameter code. Once each

setting has been entered, use the extra cycle button to advance to the next setting.

Please Note:

Most of these settings will be left alone.

Depending on your system some settings may not be shown, and some settings

may be different than shown here.

Do not change any settings unless

specifically instructed to do so by these instructions or one of our techs.

SXT Master Programming Chart

-Ensure the time is set to 12:01pm, hold BOTH up and down arrows

until programming icon appears-

>Required< This setting is required and should be

changed if it does not match

12 of 28