INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

26

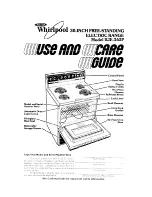

Checking the parts:

This will allow the range to be moved for cleaning or

servicing. Also, make sure your floor covering will withstand

180 °F (80 °C); see the

‘Installation Safety Instructions’

section.

Make sure the wall coverings around your range can

withstand the heat generated, up to 200 °F (90 °C), by the

range; see the

‘Installation Safety Instructions’

section.

You will also need the following tools:

1.

Electric drill

2.

Masonry drill bit & anchors (only required if installing

the range on a stone or concrete floor)

3.

Steel tape measure

4.

Phillips head screwdriver

5.

Flat head screwdriver

6.

2.5 mm Allen key (supplied with the range)

7.

Spirit level

8.

Open-end or adjustable wrench

9.

Pencil and ruler

10.

Pipe wrenches

Additional materials you may need:

•

Gas line shut-off valve.

•

Pipe joint sealant or UL-approved pipe thread tape with

Teflon* that resists action of natural and LP gases.

•

Flexible metal appliance connector (½’’ I.D.). A 5 foot

length is recommended for ease of installation

but other lengths are acceptable. Never use an old

connector when installing a new range.

•

Flare union adapter for connection to gas supply line

(¾’’ or ½’’ NPT x ½’’ I.D.).

•

Flare union adapter for connection to pressure regulator

on range (½’’ NPT x ½’’ I.D.).

•

To protect any floor covering under the range a sheet of

¼’’ thick plywood or equivalent large enough to stand

the range on.

6 grates

Allen key

ArtNo280-0084 DF Pan Supports

1 broiler rack with telescopic

runners

2 flat racks with telescopic

runners

ArtNo.326-0014 - Cradle rack (Falcon)

2 broiler pans with grids

Control knob (°C)

ArtNo.331-0008 - 90SC

grill pan & trivet

Griddle (Optional Extra)

Wok cradle (Optional Extra)

2 sets of side supports

Toe kick

ArtNo.350-0007 - Plinth USA

2 side panel extensions

Reducer plates for conduit

connection

ArtNo.351-0001 - Side extension

panel USA

ArtNo.020-0012 Reducer Plates USA

Conversion kit from natural

gas to propane gas

Anti-tip device

ArtNo.020-0019

Conversion Kit USA

*Teflon: Registered trademark of DuPont