CLEARANCES

The complete cooker is floor-mounted and the space in which the appliance is to be fitted must

have the following minimum dimensions:-

A minimum clearance of 60mm is required above the raised insulating cover handle.

Side Clearances:

A 3mm gap is required each side between the cooker top plate and adjoining

work surfaces that may be fitted, this is to allow for the safe removal of the top plate should this

be required at a later date.

Where cookers are fitted against side walls a 116mm clearance is required on the right and

left hand side for oven doors access.

If the AGA is to be installed in a brick recess, then the minimum clearance should be

increased by at least 10mm, to allow for the walls not being square.

In addition, a minimum clearance of 1000mm must be available at the front of the cooker

to enable the cooker to be serviced.

Cooker Base or Hearth

It is essential that the base or hearth on which the cooker stands should be level and be capable

of supporting the total weight of the appliance. The base of the built-in AGA plinth must be level

and sit above finished floor height for service access.

The front plinth cover is removable and must not be obstructed by flooring or tiles. If necessary

the cooker must be raised by the thickness of the tiles to ensure the plinth can be removed.

Shims are provided to eliminate rocking.

Tiling

When the cooker is to stand in a recess or against a wall which is to be tiled, in no circumstances

should the tiles overlap the cooker top plate, access to remove the top plate must be allowed for

servicing at a later date.

A gap of at least 10mm must be observed between the rear of the top plate, and the wall behind

the appliance.

6

Since this appliance can be used continuously, please take note of these

IMPORTANT

instructions:

Combustible Walls

Houses constructed of combustible materials (such as all-timber or stud wall partitions and

batoned plasterboarded walls) require special wall heat protection features.

Non-combustible walls behind a cooker must be of at least 25mm thick insulation board

(Monolux or equivalent), up to hotplate level.

In addition, oven vent piping must be insulated with the high temperature film glass sleeving,

supplied, and a 25mm gap.

SPECIAL NOTE:

Ensure electric cabling or plastic services do not pass within or on the

outside of the wall, behind or directly above the cooker.

This type of material can age prematurely when exposed to continuous higher ambient

temperature.

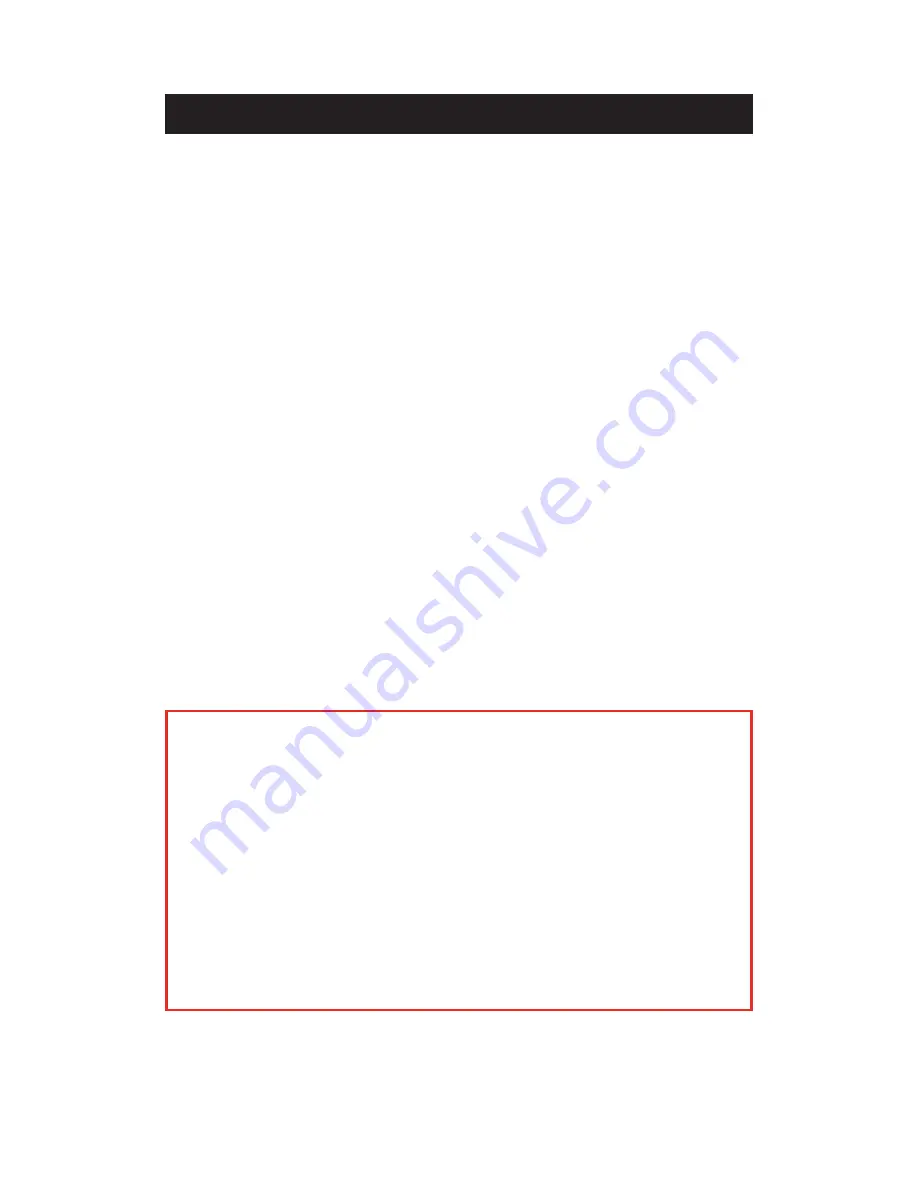

Summary of Contents for DC3

Page 20: ...WIRING DIAGRAM AGA DC3 20 Fig 20 ...

Page 23: ...23 ...