SECTION 1 - INSTALLATION

Optional Extras

A splashplate/plateshelf is available for fitting to the

G1102 open top range.

1.2 SITING

All units, other than G1112 oven on stand or legs,

must be installed on a non-combustible floor. All units

must be situated on a reasonably level surface,

although the unit feet are adjustable and facilitate

levelling, the adjustment range is limited.

Installing Clearances

A clearance of at least 150mm must be allowed from

any combustible wall.

If practicable, it is recommended that a space of at

least 400mm be allowed from any side wall to provide

clearance for adjusting the rear levelling bolts, and to

effect the removal of the RH side panel to facilitate

servicing. If the appliance is being installed as part of

a suite, it is also recommended that it be positioned at

the right-hand end to provide unrestricted access for

servicing the controls, etc.

A vertical clearance of 900mm minimum must be

allowed between the top edge of flue outlet and any

other overlying surface.

If the appliance is to be installed in a suite, either

central or adjacent to a wall, with a boxed-in void at

the rear, it is vitally important that the void be

adequately ventilated to ensure a supply of air to

the motor cooling fan at the rear of the oven.

1.3 VENTILATION

Recommendations for Ventilation of Catering

Appliances are given in BS5440 : 2. Furthermore, to

ensure sufficient room ventilation, guidance on the

volume of ventilation air required for different types of

catering equipment is provided in the table above.

For multiple installations the requirements for

individual appliances should be added together.

Installation should be made in accordance with local

and/ or national regulations applying at the time.

A competent installer MUST be employed.

The appliance flue discharges vertically through the

grill at the rear of the hob and there must be no direct

connection of the flue to any mechanical extraction

system or the outside air. Siting the appliance under a

canopy is the ideal arrangement.

1.4 GAS SUPPLY

The incoming service must be of sufficient size to

supply full rate without excessive pressure drop. A

gas meter is connected to the service pipe by the Gas

Supplier. Any existing meter should be checked by

the Gas Supplier to ensure the meter is of adequate

capacity to pass the required rate of gas.

Installation pipe work should be fitted in accordance

with IGE/UP/2. The pipe should not be smaller than

the gas inlet connection as follows:

G1102 Range:

Rc

3

/

4

(

3

/

4

" BSP female)

On the G1112 oven variants it is:

Rc

1

/

2

(

1

/

2

"BSP female)

An isolating cock must be located close to the

appliance to allow shut-down during an emergency

or servicing. The installation must be tested for gas

soundness and purged as specified in IGE/UP/1.

Note

The G1112 open top range is supplied complete with

the necessary pipework for linking oven and boiling

burner sections. The governor necessary for boiling

burners is incorporated in this pipework for Natural

Gas operation, and an extra governor must not be

fitted to any of these appliances.

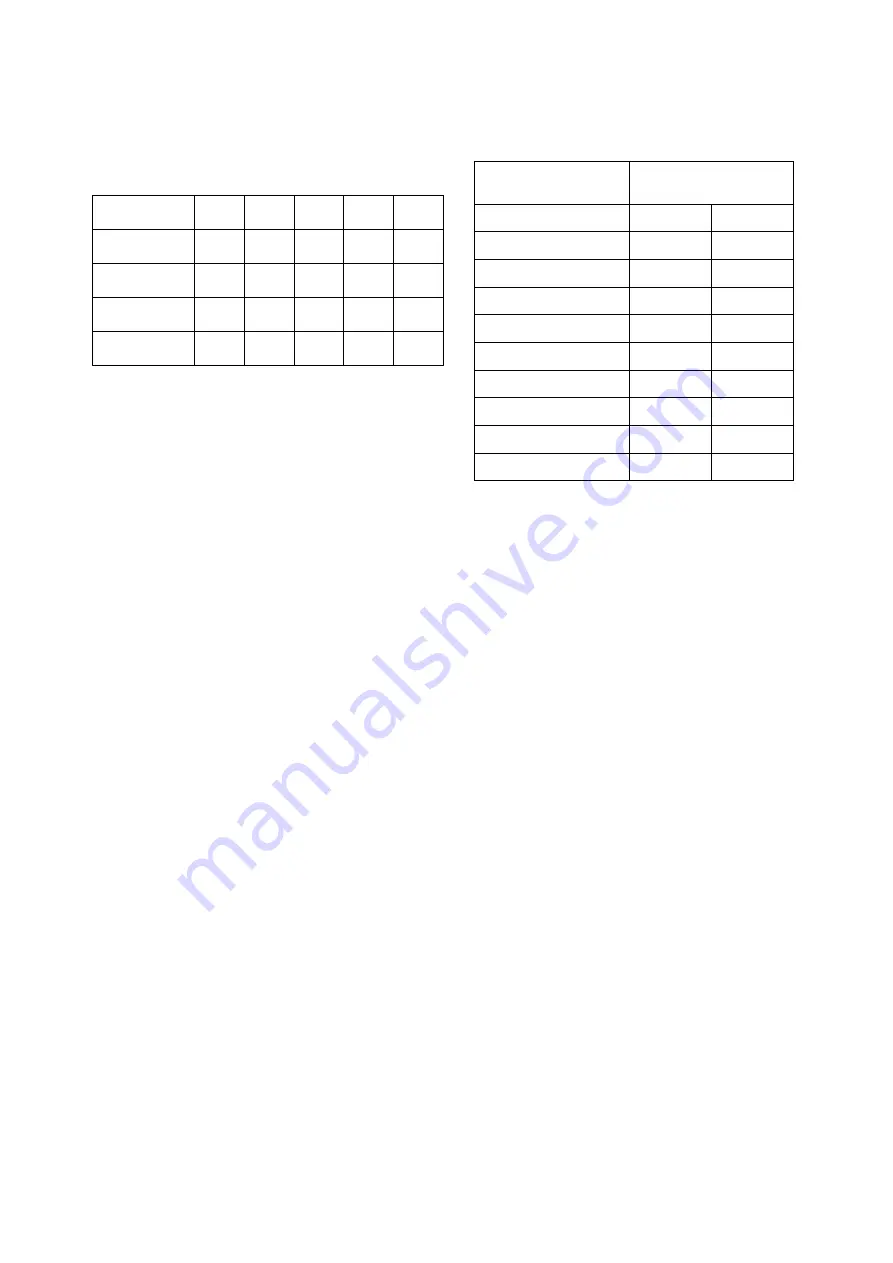

EQUIPMENT

Ventilation Rate Required

m

3

/ min

ft

3

/min

Range, Unit Type

17

600

Pastry Oven

17

600

Fryer

26

900

Grill

17

600

Steak Grill

26

900

Boiling Pan

17

600

Steamer

17

600

Sterilizing Sink

14

500

Bains Marie

11

400

Tea/ Coffee Machine

8.5 - 14

300 - 500

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER

MODEL

WIDTH

mm

DEPTH

mm

HEIGHT

mm

WEIGHT

kg

WEIGHT

lbs

G1102 RANGE

900

770

870

221

487

G1112 OVEN

ON STAND

900

770

1445

194

428

G1112/2

DOUBLE TIER

900

770

1465

364

803

G1112 OVEN

ON LEGS

900

770

870

181

399

1.1 MODEL NUMBERS, NETT WEIGHTS

and DIMENSIONS