12. Avoid contact with appliance when in use as the

stove reaches very high operating tempera-

tures.

13. This appliance should be regularly maintained

by a competent service engineer. Use only

replacement parts recommended by AGA.

Using unauthorised parts will invalidate

your guarantee and may cause damage or

injury.

14. Do not use an aerosol spray on or near the

stove when it is alight.

AN ODOUR WILL EMIT FROM STOVE ON FIRST

FIRING, WHEN FIRE REACHES MAXIMUM

TEMPERATURE OVER A NUMBER OF HOURS

THIS ODOUR WILL SUBSIDE.

IT IS BEST ADVISED TO OPEN WINDOWS

DURING THIS PERIOD.

THIS ODOUR IS UNPLEASANT BUT NOT TOXIC.

YOU MAY WISH TO VACATE THE ROOM WHILE

THE PAINT CURES.

LIGHTING

Before lighting the stove check with the installer

that the installation work and commissioning

checks described in the installation instructions

have been carried out correctly and that the

chimney has been swept clean, is sound and

free from any obstructions. As part of the stoves

commissioning and handover the installer

should demonstrate how to operate the stove

correctly.

WARNING:- The paint on the stove gets finally

cured when the stove is lit, during the first fire

the paint can soften, the doors of the stove

should be closed but not latched during the first

fire, otherwise the rope on the door can become

embedded in the paint during final curing.

IMPORTANT: The first few fires should be rela-

tively small to permit the refractory to set prop-

erly and to season the stove.

1. Before lighting the stove, ensure that any build-

up in the firebox has been removed and that the

ashpan has been emptied.

2. Open the primary air partially. Open the

secondary air to maximum open.

3. Lay some firelighters on the grate with two hand-

fuls of kindling. The kindling must be cut into thin

lengths and laid across each other in layers to

allow for a quick lightup. Ignite the firelighters and

close the door.

4. When the firebed has fully ignited and is starting

to die back add 3 small logs.

5. Approximately 2 minutes after adding the logs the

door can be closed, but air settings remain

unal tered.

6. When the fire from the 3 logs is dying back a

normal fuel load of approx 1.5kg is to be added to

the fire. Leave the air controls unaltered for 5

minutes to ensure the new fuel load is well alight

before closing the primary air control and

adjusting the secondary air control to the desired

setting.

FIRE SAFETY

To provide reasonable fire safety the following

should be given serious consideration:

1. The installation of smoke detectors.

2. A conveniently located fire extinguisher to con-

tend with small fires resulting from burning

embers.

3. A practical evacuation plan.

4. A plan to deal with a chimney fire as follows:

a.

Notify the fire department.

b. Prepare occupants for immediate evacua-

tion.

c. Close all openings into the stove.

d. While awaiting the fire department watch for

ignition to adjacent combustibles from over

head stove pipe or from embers or from

sparks from the chimney.

9

Summary of Contents for Shawbury

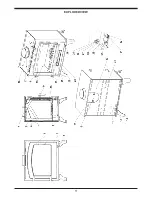

Page 12: ...11 EXPLODED VIEW...

Page 14: ...13...

Page 15: ...14...

Page 16: ...AGA Station Road Ketley Telford Shropshire TF1 5AQ UK Rev 001 DP261114 N00642AXX 15...