10

CO ALARMS

Building regulations require that whenever a

new or replacement fixed solid fuel or

wood/biomass appliance is installed in a

dwelling a carbon monoxide alarm must be fitted

in the same room as the appliance. Further

guidance on the installation of the carbon

monoxide alarm is available in BS EN

50202:2012 and from the alarm manufacturers

instructions.

Provision of an alarm must not be considered a

substitute for either installing the appliance

correctly or ensuring regular servicing and

maintenance of the appliance and chimney

system.

FIREBRICK REPLACEMENT

1.

Tilt and pull out the side Vermiculite - 1.

2.

Tilt and pull out the top rear ceiling Vermiculite -

2.

3.

Tilt and pull out the rear Vermiculite - 3.

4.

Follow the reverse sequence for assembly.

See Fig 6.

GLASS

1. How to clean:

The glass will clean itself when there is sufficient

heat generated by burning fuel. If a build-up of

creosote occurs on the glass it may be due to draft

conditions, poor quality fuel or very slow burning for

a long time. Only clean glass when the stove is

thoroughly cooled. Clean with a liquid detergent

taking care not to scratch the glass with any ash

deposits.

2. Glass Replacement:

a. Open the door fully.

b. Remove the clips and carefully remove the

broken glass.

c. Clean the glass recess in the door.

d. Place the glass into the door recess and replace

the four corner clips.

e. Tighten

screws.

f.

Replace glass only with ceramic glass 5mm

thick.

SUMMER SHUTDOWN

For summer shutdown of the stove, ensure all ashes

have been cleaned from the ash compartment and

that the air control is open, to avoid condensation in

the stove firebox and possible corrosion during this

shutdown period.

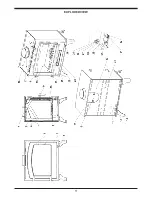

Fig 6

Note:-

Stress fractures in the firebrick do not have an effect

on the combustion or the service life of the stove,

however If the metal behind the bricks becomes

exposed from a fractured brick replace immediately

as this will cause damage to the stove.

Summary of Contents for Shawbury

Page 12: ...11 EXPLODED VIEW...

Page 14: ...13...

Page 15: ...14...

Page 16: ...AGA Station Road Ketley Telford Shropshire TF1 5AQ UK Rev 001 DP261114 N00642AXX 15...