PRE-INSTALLATION

Before using the stove for the first time all remaining

stickers must be removed, all accessories must be

removed from the ashpan, check if any items have

become dislodged during transport.

CHIMNEY/FLUES

The stove is a radiant room heater and must be con-

nected to a proper type chimney/flue for safe evac-

uation of products of combustion. The chimney/flue

must have a diameter of 150mm or equivalent cross

sectional area. Never connect to a smaller size

chimney/flue. Do not connect to a chimney/flue

serving another appliance. A minimum chimney/flue

height of 4.5 metres from the flue spigot on the stove

to the top of the chimney/flue is required. The chim-

ney/flue must be constructed of material capable of

withstanding a soot fire in the chimney/flue which

can lead to temperatures of 1000 degrees. The

chimney/flue must be constructed with sockets

uppermost so that when condensation occurs within

the pipe, it should flow down the inside of the pipe

that it will transfer to the inner of the next pipe with-

out seeping through the joints. The chimney/flue

should provide a minimum continuous draught of 12

pascals, if the stove is connected into an existing

chimney where the refractory flue liner is of a diam-

eter in excess of 200mm the chimney should be

relined using a flexible flue liner. The flexi liner is not

recommended to be connected directly to the appli-

ance, there should be a minimum of 0.6 meters rigid

flue pipe coming off the appliance. The chimney/flue

should be designed to allow for cleaning of the

stove, use pipes with cleaning doors where neces-

sary.

Avoid the use of 90 degree elbows, use 2 x 45

o

bends instead. Horizontal runs of flue pipe should

be avoided, where it is unavoidable the maximum

permitted horizontal run is 150mm. The

chimney/flue must have the necessary clearance

distance from combustible material. The chimney

termination must be free of any obstructions, see

requirements under Approved Document J, avail-

able to download at www.planningportal.gov.uk

For guidance when installing new chimney systems

or relining existing chimneys please refer to BS EN

15287:

DOWN DRAUGHTS

However well designed constructed and positioned,

the satisfactory performance of the flue can be

adversely affected by down draught caused by near-

by hills, adjacent tall buildings or trees. These can

deflect wind to blow directly down the flue or create

3

a zone of low pressure over the terminal. A suitable

anti-down draught terminal or cowl will usually effec-

tively combat direct down blow but no cowl is likely

to prevent down draught due to a low pressure zone.

(See Fig.1)

Direction of wind

Direction of wind

Direction of wind

Pressure zone

Pressure zone

Suction zone

Suction zone

Pressure zone

Suction zone

Fig 1

VENTILATION AND COMBUSTION AIR

REQUIREMENTS

Refer to extract from Building Regulations Part J to

determine size of permanent air vent.

Install where draft stabilizer is fitted:

Permanently open vents as below:

If design air permeability >5.0m

3

/(h.m

2

) then

300mm

2

/kW for first 5kW of appliance rated output

850mm

2

/kW for balance of appliance rated output

If design air permeability <5.0m

3

/(h.m

2

) then

850mm

2

/kW of appliance rated output (4)

Install where no draft stabilizer is fitted:

Permanently open vents as below:

If design air permeability >5.0m

3

/(h.m

2

) then

550mm

2

/kW of appliance rated output above 5kW

If design air permaeability <5.0m

3

/(h.m

2

) then

550mm

2

per kW of appliance rated output (4)

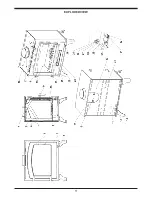

Summary of Contents for Shawbury

Page 12: ...11 EXPLODED VIEW...

Page 14: ...13...

Page 15: ...14...

Page 16: ...AGA Station Road Ketley Telford Shropshire TF1 5AQ UK Rev 001 DP261114 N00642AXX 15...