18

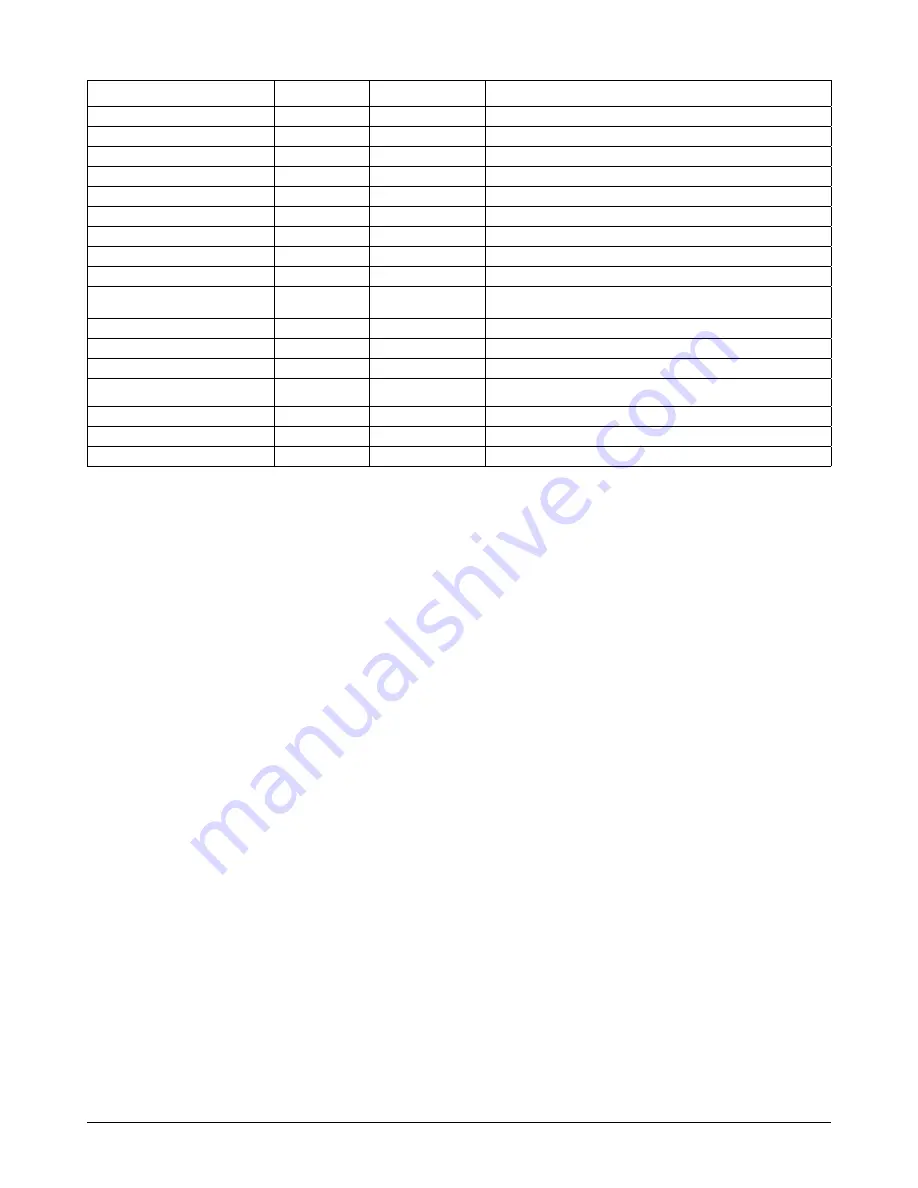

Cakes & Biscuits

Shortbread

140 - 150

1 1/4 - 1 1/2 hrs

Very Rich Fruit Cake

120 - 130

3 - 4 hrs

Rich Fruit Cake

130

4 - 41/2 hrs

Small Cakes

170 - 180

20 - 25 mins

Scones

200 - 210

10 - 15 mins

Victoria Sandwich

160 - 170

25 - 30 mins

Swiss Roll

200 - 210

7 - 10 mins

Biscuits

130 - 180

1 1/4 - 1 1/2 hrs

Tray Bakes & Tea Breads

160 - 170

30 mins - 1 1/2 hours depending on recipe

Shortcrust Pastry

190

Small Tarts 20 - 25 mins depending on recipe,

Pies 45 - 50 mins depending on recipe

Rich Shortcrust

180

25 mins

Flaky/Puff Pastry

210

8 - 20 mins depending on recipe

Choux Pastry

190 - 200

25 - 35 mins

Miscellaneous

Yorkshire Pudding - large

200

45 mins

Yorkshire Pudding - individual

200

20 - 25 mins

Soufflès

170 - 180

45 mins