Important Warnings and Instructions

4

/

42

WARNING

READ ALL INSTRUCTIONS BEFORE ASSEMBLING OR USING THIS EQUIPMENT

AGE LIMIT

•

This product is designed to be used by up to six (6) children between the ages of 3 to 8.

Maximum user weight is 100 pounds (45.4kg) each with a combined maximum weight of 600

pounds (272kg).

•

The play set is designed for children over three (3) years of age. Use by smaller children can

result in entrapment.

•

On-site adult supervision is required at all times for children of all ages.

•

Do not allow use by children with any physical condition that may affect his/her ability to use this

equipment safely.

BEFORE YOU BEGIN

•

Carefully read all instructions in this manual before assembling and using this product.

•

The unit must be assembled by adults. Heavy-duty working gloves must be worn to avoid injuries

during assembly.

•

Children must not use the equipment until properly assembled and anchored.

•

Adult supervision is required during the use of this equipment at all times.

•

Unpack all parts. Take a complete inventory of all parts and hardware using the parts and

hardware lists in the following pages. If any parts are missing, do not return to the store. Please

call customer service toll-free number listed on the cover page for assistance. Store the product

back in the original box and do not begin to install until all parts are obtained.

•

Never add extra length to chain or rope. The chains or ropes provided are the maximum length

designed for the swinging element(s).

LOCATION OF PLAY SET

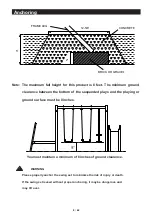

•

The equipment must be placed more than six (6) feet (1.8 meter) from any structures or

obstructions, including but not limited to buildings, fence, garage, trees, laundry lines, electrical

wires. Children can be seriously injured running or swinging into obstacles.

•

The play set must be installed on level ground. Uneven ground must be leveled prior to

installation. Installation on sloping or uneven ground will put stress on the joints, causing the unit

to become loose and unstable which may result in serious injuries.

•

Remove any tripping hazards from the safe play area, such as roots, tree stumps, rocks,

landscaping, sprinkler heads, railroad ties, plumbing and electrical connections.

Summary of Contents for 164176

Page 12: ...12 42 Complete Product View ...