18

AGC Stopray SMART

–

Processing Guide

–

Version 4.1

–

May 2020

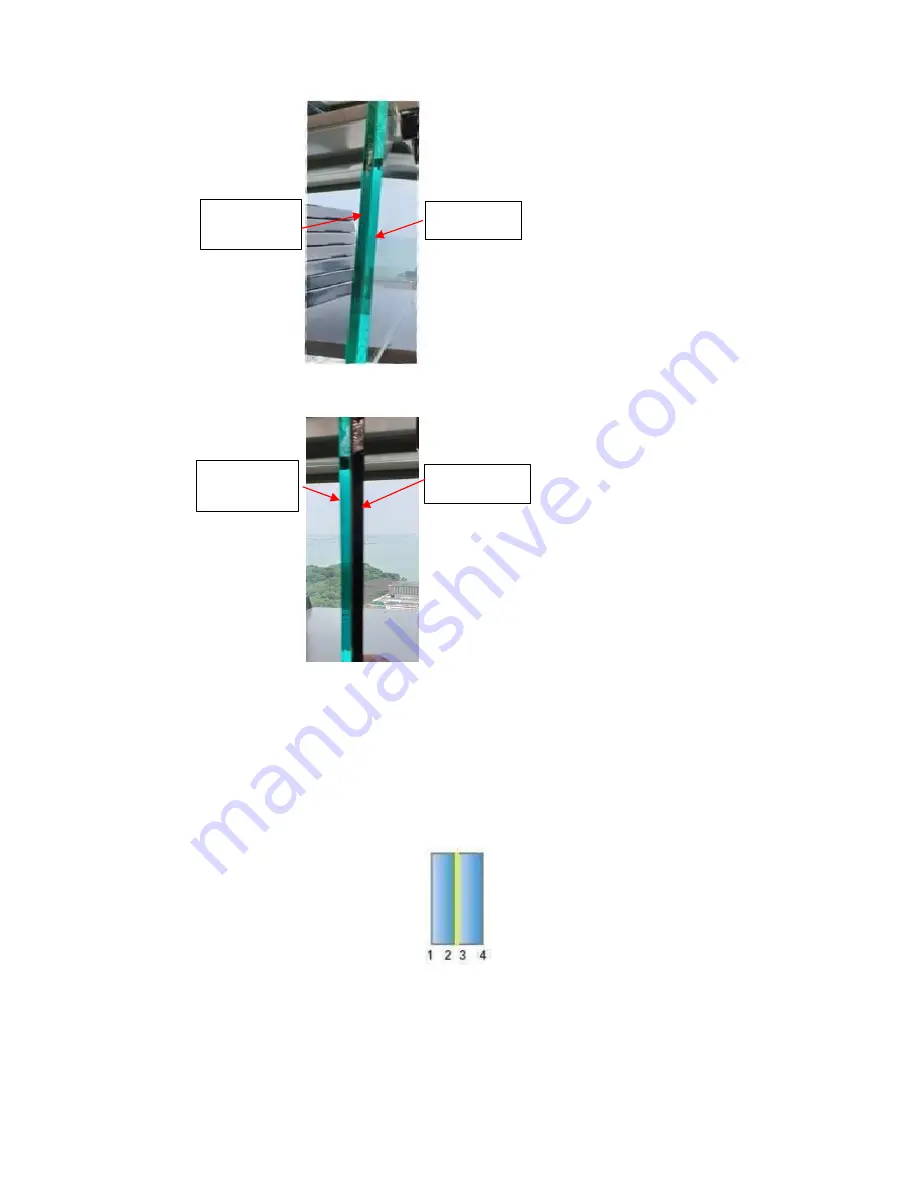

b)

Laminated with Tinted glass – coated glass will have higher transmittance.

• Above methods are ONLY for your reference. Should you have your own way of identifying the glass

coating position, kindly enforce it and continue to maintain the good practice.

Glazing systems should be designed to prevent de-lamination or corrosion of the inside coating.

The processor is responsible for glazing. The correct lamination and safety compliance is the

responsibility of the processor.

Clear glass

Coating on

Pos 2

Tinted glass

Coating on

Pos 2