OPERATION

05.6

Operation

11-04

RoGator 418

Automatic Adjustment of the

Track Width (Option)

When adjusting the track width hydraulically it is

possible to slide between two different tracks. With

out repositioning the track lock disc and adjusting

the pins in the adjustment bar.

When the track lock disc is turned into another po-

sition and the pins in the adjustment bar are put into

another hole, other track widths can be set. This

results in the following track widths:

1.

1.50 m and 2.00 m

2.

1.80 m and 2.25 m

3.

2.00 m and 2.25 m

Track widths can be different if the track lock disc is

customer built.

Track width 1.50 m is only available on tires 300/95

R46.

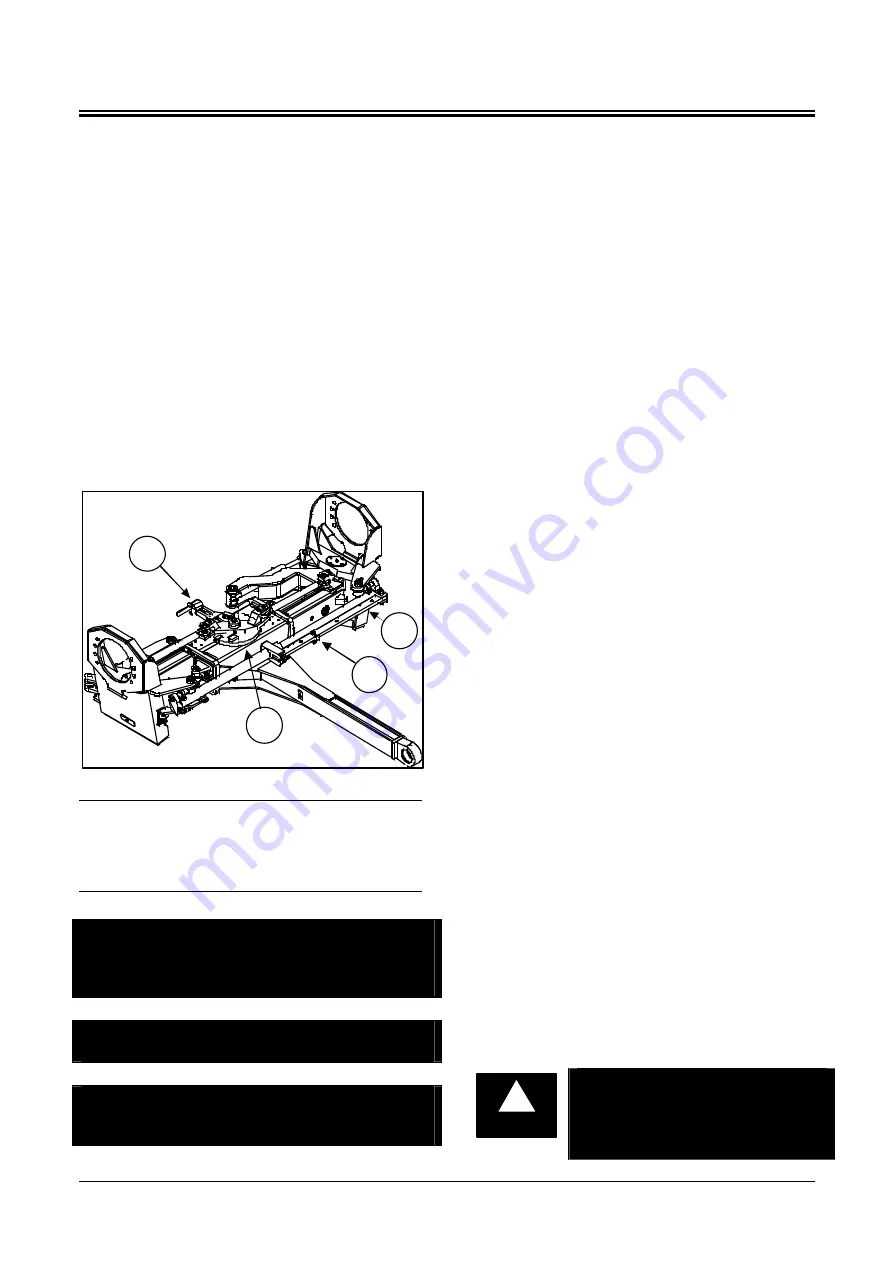

Adjustable (Front) Axle

1.

Locking pin

2.

Track Lock Disc

3.

Adjustment bar

4.

Pin

NOTE: In order to be able to set the track width,

the traction control lever must be moved out of

neutral, field mode must be selected and the lock

switch must be on.

NOTE: Track width 1.50 m is only available on

tires 300/95 R46.

NOTE: Track lock disc and adjustment bar need

to be changed when other tires or rims are

mounted.

Sliding the Axle

If the track lock disc and the adjustment bar are

fixed in either position one, two or three the axle

can be sledded as following:

1. Depress the switch for the track width lock, and

put the field / road switch in the field position.

2. To change the track width of the rear axle, move

the traction control lever slightly forward so that

the machine drives forward slowly. Then press

the switch for changing the rear axle track

width. Hold the button depressed until the bar

on the track lock disc is pressed against the

stop and the pin in the adjustment bar is

pressed against the stop.

3. To change the front axle track width, move the

traction control lever back so that the machine

reverses slowly. Then press the switch for

changing the front axle track width. Hold the

button depressed until the bar on the track lock

disc is pressed against the stop and the pin in

the adjustment bar is pressed against the stop.

4. Unlock the switch for track width lock.

Setting the Track Width

The axle can slide between two different tracks de-

fined by the position of the track lock disc and the

pins in the adjustment bar. Other tracks can be

chosen by putting the track lock discs and the pins

in the adjustment bar in another position. The tracks

can be set as following:

1. Slide the axle a little bit in or out so that there is

no tension on the locking pin in the track lock

disc and the pins in the adjustment bar.

2. Pull the locking pin back. The track lock disc

can be turned now. Put the locking pin in the

bore hole corresponding to the track widths you

need. See pictures on page 5.6 and 5.7. Slide

the axle a bit in or out when the stops on the

track lock disc hit the bar and prevent the disc

from turning.

3. Take out the pins in the adjustment bar. Put the

pins on the right place into the adjustment bar

corresponding to pictures on page 5.6 and 5.7.

All the pins are marked. Every track width has

its own pin. The pins are marked with either “F”,

Front axle or “R”, Rear axle and the track width.

On track width 2.25 m no pin is used. Don’t

swap pins. This will result in a wrong toe-in ad-

justment.

WARNING

!

Caution: Don’t swap pins on the

adjustment bar. This can result in

a wrong toe-in adjustment. On

track width 2.25 m no pin is used.

1

2

3

4