198935 R17

17

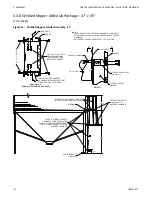

Figure 2.

Product Storage

3. White rust is not a structural concern if its development is stopped in the early stages. A

light film or powdery residue can occur after a period of heavy rainfall or a short time of

improper storage. If white rust has started to develop, separate parts and wipe off any

moisture. Next, using a clean cloth, apply a thin layer of petroleum jelly or food-grade oil

to the entire part.

4. If moisture is left on parts, this white rust can become more aggressive and turn into red

rust. Red rust can cause degradation in the material and become a structural concern.

Any parts that have red rust should be replaced immediately.

Storage Guidelines

1. Keep all bundles dry before assembly of the

bin. Start assembly as soon as possible. Do not

lay bundles on the bare ground, raise all bundles

6” – 8” off the ground on wood blocks or timbers.

Store curved wall sheets ‘hump-up’. All other

bundles material should be placed so that they are

well sloped to promote good drainage.

2.

Roof sheets must be elevated at least 12” at the

small end of the sheets.

3. Temporary storage can be provided by erecting

a simple framework supporting a waterproof tarp.

4. All bin boxes, ladder boxes and hardware boxes should be stored inside. These are not

waterproof, and will deteriorate in normal weather conditions, allowing moisture to contact

the parts inside.

If Parts Become Wet

1. If goods become submerged or wet, the

bundles should be opened as soon as possible,

sheets or material separated and dried. Keep

separated until assembly. Brace goods

properly so as to avoid damage or injury from

material falling when in storage.

2. Any boxed goods that become wet should be dried and stored in a new box that is free of

moisture.

3. In addition to wiping down wallsheets, a food-grade oil can also be applied with a clean,

lint-free cloth. This will assist in preventing any further moisture from contacting the

galvanizing on the steel. Due to safety concerns with installation and use, Westeel does

not recommend the use of oil on other parts such as roof sheets and safety ladders.

Page A10

A

3. White rust is not a structural concern if its development is stopped in the early stages. A

light film or powdery residue can occur after a period of heavy rainfall or a short time of

improper storage. If white rust has started to develop, separate parts and wipe off any

moisture. Next, using a clean cloth, apply a thin layer of petroleum jelly or food-grade oil

to the entire part.

4. If moisture is left on parts, this white rust can become more aggressive and turn into red

rust. Red rust can cause degradation in the material and become a structural concern.

Any parts that have red rust should be replaced immediately.

Storage Guidelines

1. Keep all bundles dry before assembly of the

bin. Start assembly as soon as possible. Do not

lay bundles on the bare ground, raise all bundles

6” – 8” off the ground on wood blocks or timbers.

Store curved wall sheets ‘hump-up’. All other

bundles material should be placed so that they are

well sloped to promote good drainage.

2.

Roof sheets must be elevated at least 12” at the

small end of the sheets.

3. Temporary storage can be provided by erecting

a simple framework supporting a waterproof tarp.

4. All bin boxes, ladder boxes and hardware boxes should be stored inside. These are not

waterproof, and will deteriorate in normal weather conditions, allowing moisture to contact

the parts inside.

If Parts Become Wet

1. If goods become submerged or wet, the

bundles should be opened as soon as possible,

sheets or material separated and dried. Keep

separated until assembly. Brace goods

properly so as to avoid damage or injury from

material falling when in storage.

2. Any boxed goods that become wet should be dried and stored in a new box that is free of

moisture.

3. In addition to wiping down wallsheets, a food-grade oil can also be applied with a clean,

lint-free cloth. This will assist in preventing any further moisture from contacting the

galvanizing on the steel. Due to safety concerns with installation and use, Westeel does

not recommend the use of oil on other parts such as roof sheets and safety ladders.

Page A10

B

3. White rust is not a structural concern if its development is stopped in the early stages. A

light film or powdery residue can occur after a period of heavy rainfall or a short time of

improper storage. If white rust has started to develop, separate parts and wipe off any

moisture. Next, using a clean cloth, apply a thin layer of petroleum jelly or food-grade oil

to the entire part.

4. If moisture is left on parts, this white rust can become more aggressive and turn into red

rust. Red rust can cause degradation in the material and become a structural concern.

Any parts that have red rust should be replaced immediately.

Storage Guidelines

1. Keep all bundles dry before assembly of the

bin. Start assembly as soon as possible. Do not

lay bundles on the bare ground, raise all bundles

6” – 8” off the ground on wood blocks or timbers.

Store curved wall sheets ‘hump-up’. All other

bundles material should be placed so that they are

well sloped to promote good drainage.

2.

Roof sheets must be elevated at least 12” at the

small end of the sheets.

3. Temporary storage can be provided by erecting

a simple framework supporting a waterproof tarp.

4. All bin boxes, ladder boxes and hardware boxes should be stored inside. These are not

waterproof, and will deteriorate in normal weather conditions, allowing moisture to contact

the parts inside.

If Parts Become Wet

1. If goods become submerged or wet, the

bundles should be opened as soon as possible,

sheets or material separated and dried. Keep

separated until assembly. Brace goods

properly so as to avoid damage or injury from

material falling when in storage.

2. Any boxed goods that become wet should be dried and stored in a new box that is free of

moisture.

3. In addition to wiping down wallsheets, a food-grade oil can also be applied with a clean,

lint-free cloth. This will assist in preventing any further moisture from contacting the

galvanizing on the steel. Due to safety concerns with installation and use, Westeel does

not recommend the use of oil on other parts such as roof sheets and safety ladders.

Page A10

C

3. White rust is not a structural concern if its development is stopped in the early stages. A

light film or powdery residue can occur after a period of heavy rainfall or a short time of

improper storage. If white rust has started to develop, separate parts and wipe off any

moisture. Next, using a clean cloth, apply a thin layer of petroleum jelly or food-grade oil

to the entire part.

4. If moisture is left on parts, this white rust can become more aggressive and turn into red

rust. Red rust can cause degradation in the material and become a structural concern.

Any parts that have red rust should be replaced immediately.

Storage Guidelines

1. Keep all bundles dry before assembly of the

bin. Start assembly as soon as possible. Do not

lay bundles on the bare ground, raise all bundles

6” – 8” off the ground on wood blocks or timbers.

Store curved wall sheets ‘hump-up’. All other

bundles material should be placed so that they are

well sloped to promote good drainage.

2.

Roof sheets must be elevated at least 12” at the

small end of the sheets.

3. Temporary storage can be provided by erecting

a simple framework supporting a waterproof tarp.

4. All bin boxes, ladder boxes and hardware boxes should be stored inside. These are not

waterproof, and will deteriorate in normal weather conditions, allowing moisture to contact

the parts inside.

If Parts Become Wet

1. If goods become submerged or wet, the

bundles should be opened as soon as possible,

sheets or material separated and dried. Keep

separated until assembly. Brace goods

properly so as to avoid damage or injury from

material falling when in storage.

2. Any boxed goods that become wet should be dried and stored in a new box that is free of

moisture.

3. In addition to wiping down wallsheets, a food-grade oil can also be applied with a clean,

lint-free cloth. This will assist in preventing any further moisture from contacting the

galvanizing on the steel. Due to safety concerns with installation and use, Westeel does

not recommend the use of oil on other parts such as roof sheets and safety ladders.

Page A10

D

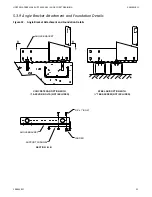

If Parts Become Wet

1. If parts become submerged or wet, the bundles should be opened as soon as possible, sheets or material

separated and dried. Keep separated until assembly.

Brace parts properly so as to avoid damage or injury from material falling when in storage. (See Detail D in

.)

2. Any boxed parts that become wet should be dried and stored in a new box that is free of moisture.

3. In addition to wiping down wall sheets, a food-grade oil can also be applied with a clean, lint-free cloth. This

will assist in preventing any further moisture from contacting the galvanizing on the steel. Due to safety

concerns with installation and use, Westeel does not recommend the use of oil on other parts such as roof

sheets and safety ladders.

3.7. Grain Bin Use

• Do not off-center unload a grain bin. It is imperative to unload from the center of the bin first, until as much

grain as possible has been removed, and only then proceed to unload from the next closest unload gate to

the center. Continue utilizing the unload gates in succession from the center towards the outside. Gate

control mechanisms should be clearly marked and interconnected to prevent an external gate from being

opened first.

• The only exception to center unloading is when a properly designed and installed side draw system is

utilized. However, as bins tend to go out of round when employing side draws, the bin must be completely

emptied before refilling.

• When unloading a bin with a mobile auger through a properly designed auger chute, the entry end of the

auger should be pushed into the center of the bin before the auger is engaged. Slower rates of flow are

preferable and should not exceed the capacity of an 8” auger.

• Ensure that the inner door panels of grain bin doors are completely closed and latched before filling the

grain bin.

• Never enter a loaded grain bin for any reason. Grain can be a killer.

HOPPER LADDER MAKE-UP PACKAGES – WIDE-CORR® GRAIN BIN