28

198935 R17

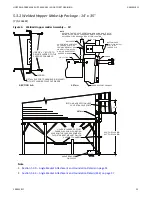

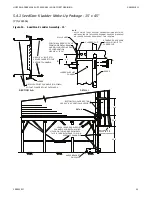

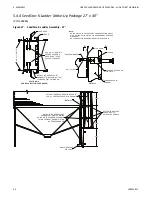

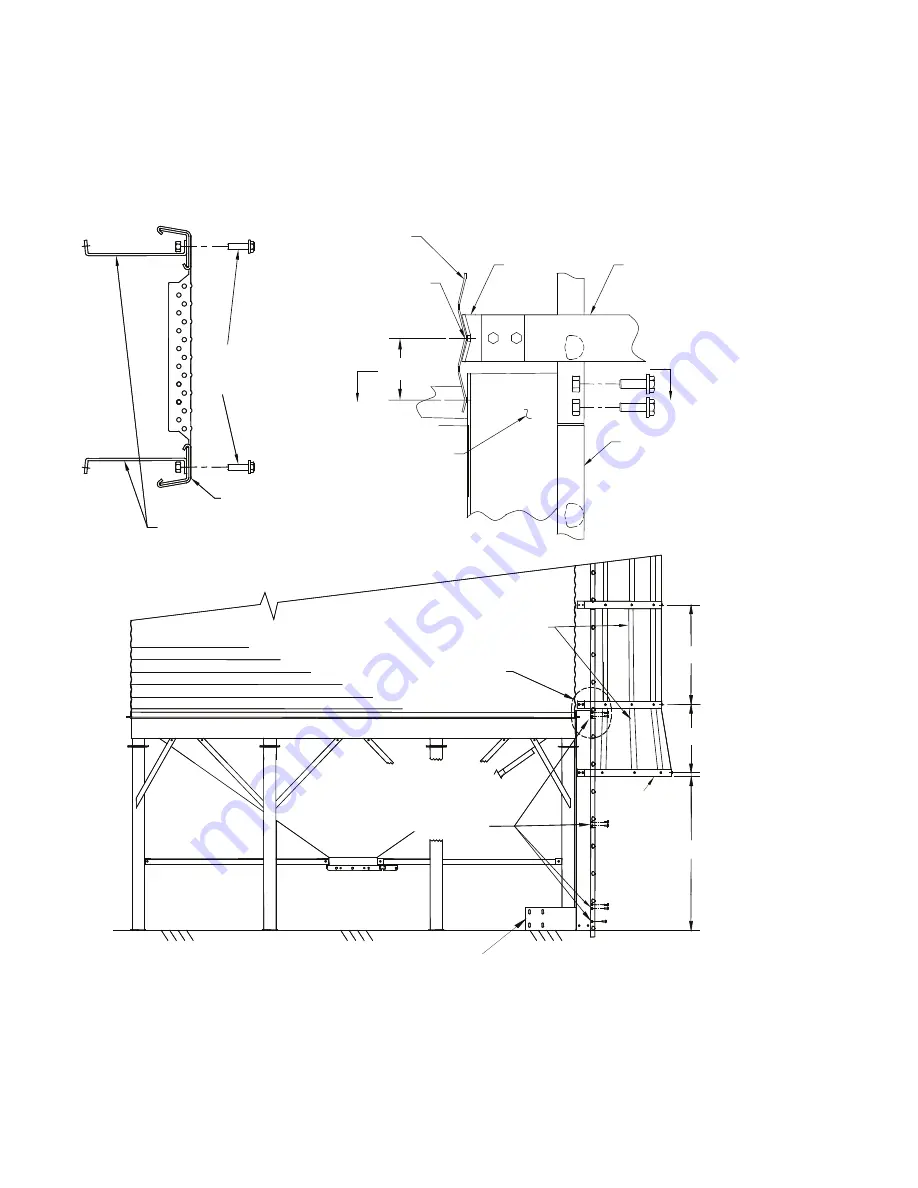

5.3.6 Welded Hopper Make-Up Package - 21' x 35°

(P/N 234533)

Figure 9.

Welded Hopper Ladder Assembly - 21’

HOLES IN LADDER SUPPORT

CHANNELS ALIGN WITH MATING

HOLES ON THE LADDER SEGMENTS.

THIS IS THE BEST MEANS TO ALIGN

SUPPORT CHANNELS

ANGLE BRACKET

P/N 234522

DETAIL 1

BOTTOM TWO CAGE SECTIONS

USES 25” & 40” VERTICAL SUPPORTS

40.0”

88.4”

25.0”

BOTTOM CAGE

HOOPS BOLT TO

SUPPORT CHANNELS

LADDER

INSTALL SUPPORT CHANNELS (P/N 234492)

SO THAT FLANGES POINT OUTWARDS

USE 3/8” x 1” BOLTS TO

SECURE LADDER TO THE

SUPPORT CHANNELS

SECTION A–A

LADDER

LADDER SUPPORT

CHANNEL

4.0”

WC LADDER CLIP

STANDARD CAGE HOOP

(P/N 234161) BOLT TO

LADDER CLIP

POSITION LADDER CLIP 4”

UP

FROM HORIZONTAL SEAM

AND DRILL HOLES ON CREST

OF CORRUGATION.

USE 3/8” x 1” BOLT

WALL SHEET

DETAIL 1

A

A

NOTE:

-

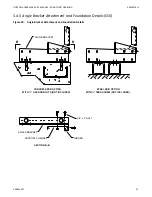

HOLES ON THE TOP OF SUPPORT CHANNELS ALIGN & BOLT WITH

MATING HOLES ON THE LADDER SEGMENT & HOPPER RING BEAM

-

W

C

LADDER CLIPS ARE REQUIRED AT THIS LOCATION

HOPPER LADDER MAKE-UP PACKAGES – WIDE-CORR® GRAIN BIN