To remove and replace the CPU board

1

Using previous procedures, remove the following assemblies:

•

Handle

•

Rear Feet

•

Cover

•

Disk Drive Assembly

•

Acquisition Board

2

Disconnect the following cables from the CPU board:

C A U T I O N

When reconnecting the cables, the ribbon cable from the CPU Board to the Acquisition Board

must not be connected to J12. This cable goes from the CPU Board to J13 (at the edge of the

Acquisition Board). If the cable is connected to J12 on the Acquisition Board equipment

damage will occur.

•

Rear Panel (J5)

•

LCD Data (J4)

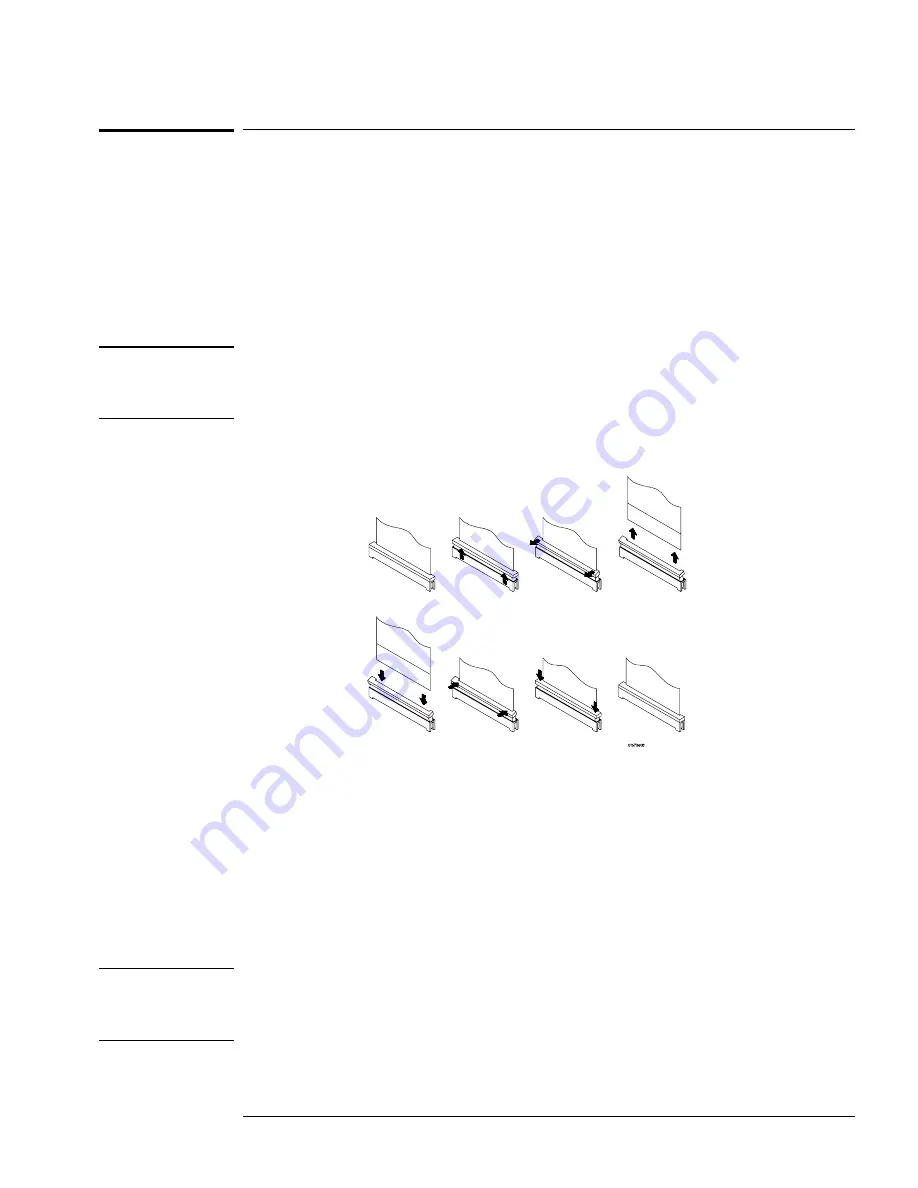

Removing the LCD data cable from the CPU board

•

LCD Inverter (J3)

•

GPIB (J13)

•

RS-232 (J8)

•

Front Panel (J7)

3

Slide the board out the side of the instrument.

4

Reverse this procedure to install the CPU board.

When connecting the LCD data cable to the CPU board, ensure the blue side of the

cable faces away from the SIMM memory.

C A U T I O N

When reconnecting the cables, the ribbon cable from the CPU Board to the Acquisition

Board must not be connected to J12. This cable goes from the CPU Board to J13 (at the edge

of the Acquisition Board). If the cable is connected to J12 on the Acquisition Board

equipment damage will occur.

Check that the following assemblies are properly installed before installing the CPU board:

Replacing Assemblies

To remove and replace the CPU board

6–9

Summary of Contents for 1670G Series

Page 20: ...1 12...

Page 116: ...Testing Performance Performance Test Record pattern generator 3 92...

Page 126: ...Calibrating and Adjusting To test the CAL OUTPUT ports 4 10...

Page 166: ...Exploded View of the Agilent 1670G series logic analyzer Replacing Assemblies 6 4...

Page 201: ...Theory of Operation The Oscilloscope Board 8 11...