43

Chapter 3: Testing Performance

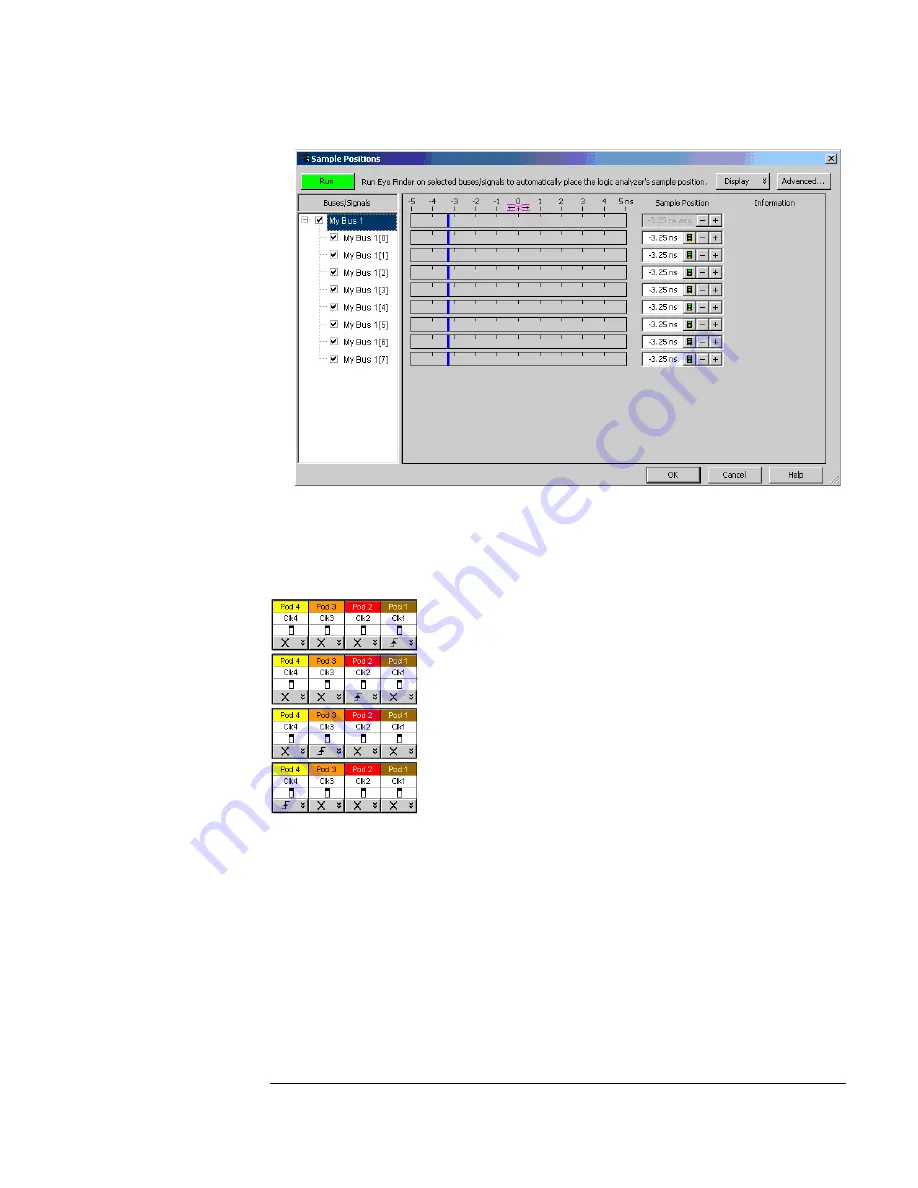

To test the single-clock, single-edge, state acquisition

d

Click OK to close the Sample Positions dialog.

4

Select the clock to be tested:

The following clock configurations will be used in steps 4, 5, and 6.

a

In the Analyzer Setup dialog, click on the Sampling tab.

b

In the Sampling tab, click the Master button for the first clock to be

tested (Clk 1) and select Rising Edge.

Summary of Contents for 1680 series

Page 13: ...13 Chapter 1 General Information Dimensions 1680A AD Series 1690A AD Series...

Page 74: ...74 Chapter 3 Testing Performance Performance Test Record...

Page 142: ...142 Chapter 6 Replacing Assemblies 1690A AD series disassembly assembly...

Page 172: ...172 Chapter 8 Theory of Operation Self Tests Descriptions...

Page 174: ......