6- 7

Replacing Assemblies

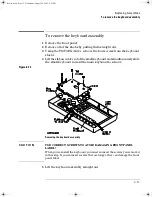

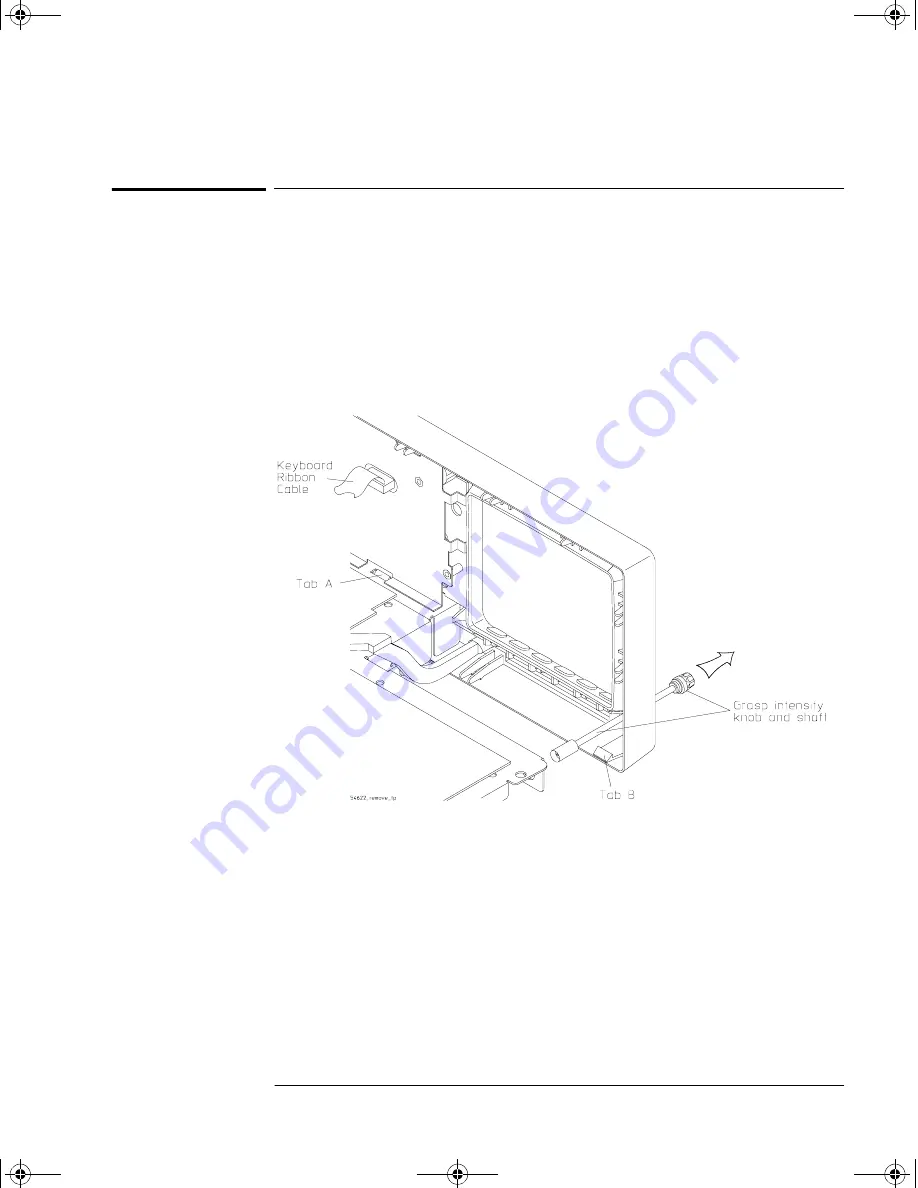

To remove the front panel

To remove the front panel

1

Remove the intensity knob and shaft by grasping the knob with one

hand and the grasping the shaft behind the front panel with the other

hand and pulling the shaft straight out from the front panel.

2

Disconnect the keyboard ribbon cable W2 from the keyboard.

3

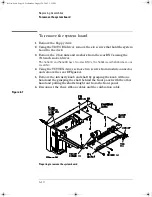

Use a screwdriver to release retainer tab A, and your finger to release

retainer tab B. See the tab locations in Figure 6-4.

Figure 6-4

Removing the intensity shaft and front panel

4

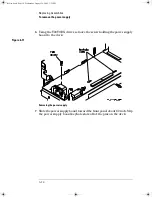

Swing the front panel out until the bottom clears the deck assembly,

then lift it up to free the hooks on top and pull it away from the deck.

When installing the front panel, make sure that the power switch shaft is aligned

with the connection hole in the front panel to make a proper connection.

Before engaging the retainer tabs, make sure that all of the hooks on top of the

front panel are fully engaged with their connection holes in the sheet metal.

Then swing the front panel in to engage the two retainer tabs.

service.book Page 7 Wednesday, August 28, 2002 3:25 PM

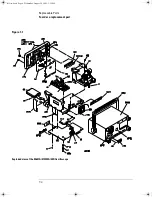

Summary of Contents for 54641A

Page 4: ...iv service book Page iv Wednesday August 28 2002 3 25 PM ...

Page 7: ...1 General Information ...

Page 24: ...1 18 ...

Page 25: ...2 Preparing the Oscilloscope for Use service book Page 1 Wednesday August 28 2002 3 25 PM ...

Page 45: ...3 Testing Performance service book Page 1 Wednesday August 28 2002 3 25 PM ...

Page 66: ...3 22 service book Page 22 Wednesday August 28 2002 3 25 PM ...

Page 67: ...4 Calibrating and Adjusting service book Page 1 Wednesday August 28 2002 3 25 PM ...

Page 76: ...4 10 service book Page 10 Wednesday August 28 2002 3 25 PM ...

Page 77: ...5 Troubleshooting service book Page 1 Wednesday August 28 2002 3 25 PM ...

Page 90: ...5 14 service book Page 14 Wednesday August 28 2002 3 25 PM ...

Page 91: ...6 Replacing Assemblies service book Page 1 Wednesday August 28 2002 3 25 PM ...

Page 107: ...7 Replaceable Parts service book Page 1 Wednesday August 28 2002 3 25 PM ...

Page 114: ...7 8 service book Page 8 Wednesday August 28 2002 3 25 PM ...