FINAL

TRIM

SIZE

:

7.5

in

x

9.0

in

Calibration

Overview

User

Calibrations

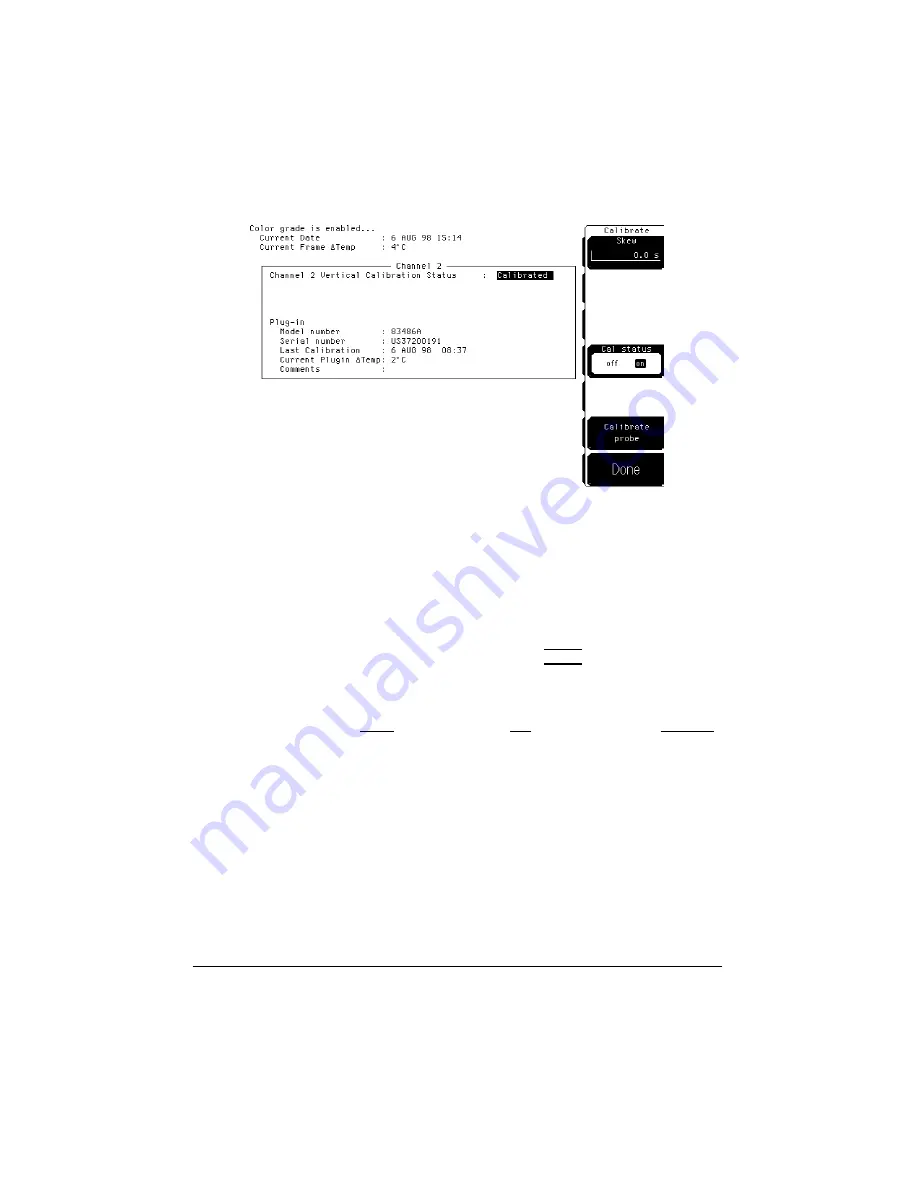

Figure

3-3.

Electrical

Channel

Calibrate

Menu

T

o

calibrate

other

devices

Since

the

mainframe's

CAL

signal

is

a

voltage

source

,

it

cannot

be

used

to

calibrate

to

the

probe

tip

when

the

units

are

set

to

Ampere

,

W

att,

or

Unknown.

Instead,

set

the

external

gain

and

external

oset

to

compensate

for

the

actual

characteristics

of

the

probe

or

device

.

If

you

do

not

know

the

actual

characteristics

,

you

can

refer

to

the

typical

specications

that

came

with

the

probe

or

device

.

1.

Press

the

plug-in

module's

front-panel

channel

4

SETUP

5

key

.

2.

Press

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

External

scale

.

3.

Press

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Atten

units

Ratio

,

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Attenuation

1:1,

and

then

NNNNNNNNNNNNNNNNN

Units

Ampere

(V

olt,

W

att,

or

Unknown).

4.

Press

NNNNNNNNNNNNNNNNNNNNNNNNNN

Ext

gain

,

and

enter

the

actual

gain

characteristics

of

the

probe

or

device

.

5.

Press

N

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Ext

offset

,

and

enter

the

oset

introduced

by

the

probe

or

device

.

3-12

Summary of Contents for 54751A

Page 1: ......

Page 8: ...FINAL TRIM SIZE 7 5 in x 9 0 in Declaration of Conformity vii ...

Page 9: ...FINAL TRIM SIZE 7 5 in x 9 0 in viii ...

Page 15: ...FINAL TRIM SIZE 7 5 in x 9 0 in Contents ...

Page 16: ...FINAL TRIM SIZE 7 5 in x 9 0 in 1 The Instrument at a Glance ...

Page 22: ......

Page 25: ...FINAL TRIM SIZE 7 5 in x 9 0 in TheInstrumentata Glance ...

Page 26: ...FINAL TRIM SIZE 7 5 in x 9 0 in 2 Channel Setup Menu ...

Page 28: ...FINAL TRIM SIZE 7 5 in x 9 0 in ChannelSetupMenu Figure2 1 ElectricalChannel Setupmenu 2 3 ...

Page 38: ...FINAL TRIM SIZE 7 5 in x 9 0 in 3 Calibration Overview ...

Page 52: ...FINAL TRIM SIZE 7 5 in x 9 0 in 4 Speci cations and Characteristics ...

Page 60: ......

Page 67: ...FINAL TRIM SIZE 7 5 in x 9 0 in InCaseofDi culty ...