16 Verification

e.

Divide the voltage drop (DVM reading) across the current monitoring resistor by its resistance to convert to amps and

record this value (Iout). Also, record the current reading that appears on the front panel display. The readings should be

within the limits specified in the performance test record form for the appropriate model under CC PROGRAMMING

@ FULL-SCALE.

Current Sink (CC-) Operation.

This test verifies current sink operation and readback.

a.

Turn off the supply and connect the output as shown in Figure 2-1, except connect a DC power supply in place of the

electronic load as indicated.

b.

Set the external power supply to 5 V and its current limit to 20% of the full scale current value (see Table 2-3) of the

supply under test. For example, if the full scale current value is 25 A, set the external supply’s current limit to 5 A.

c.

Turn on the supply under test and program the output voltage to zero. The current on the UUT display should be

approximately 20% of the full-scale current.

d.

Divide the voltage drop across the current monitoring resistor by its resistance to obtain the current sink value in amps

and subtract this from the current reading on the display. The difference between the readings should be within the

limits specified in the Performance Test Record Form for the appropriate model under, CURRENT SINK DISPLAY

AND READBACK.

CC Load and Line Regulation

These tests (CC Load Effect and CC Source Effect given below) are tests of the DC regulation of the power supply’s output

current. To insure that the values read are not the instantaneous measurement of the AC peaks of the output current ripple,

several DC measurements should be made and the average of these reading calculated. An example of how to do this is

given below using an Agilent 3458A System Voltmeter programmed from the front panel. Set up the voltmeter and execute

the “Average Reading” program as follows:

a.

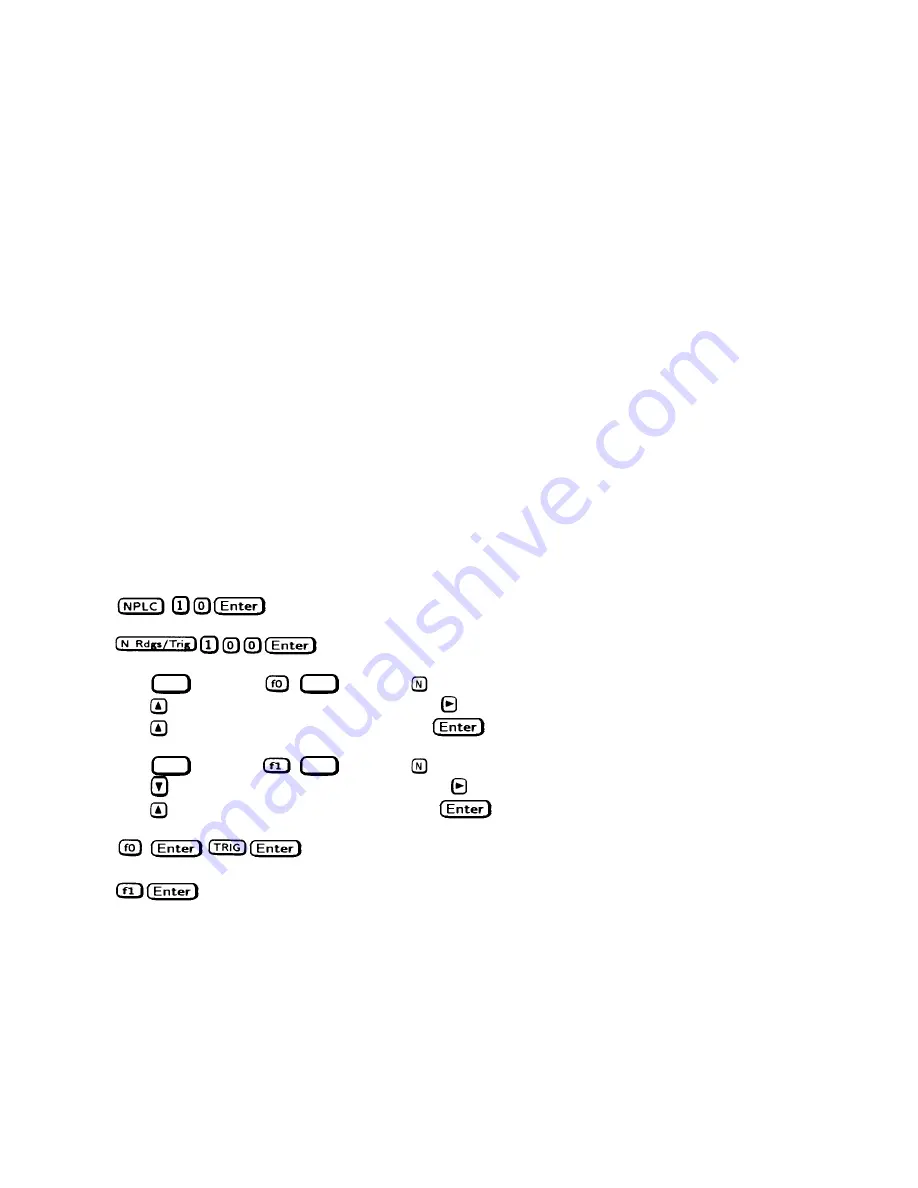

Program 10 power line cycles per sample by pressing

.

b.

Program 100 samples per trigger by pressing

.

c.

Set up voltmeter to take measurements in the statistical mode as follows:

Press

(shift key)

(shift key)

.

Press

until MATH function is selected, then press

.

Press

until STAT function is selected, then press

.

d.

Set up voltmeter to read the average of the measurements as follows:

Press

(shift key)

(shift key)

.

Press

until RMATH function is selected, then press

.

Press

until MEAN function is selected, then press

.

e.

Execute the program by pressing

.

f.

Wait for 100 readings and then read the average measurement by pressing

.

To repeat the measurement, perform steps (e) and (f).

CC Load Effect

This test measures the change in output current for a change in the load from full scale output voltage to short circuit.

a.

Turn off the supply and connect the output as shown in Figure 2-1 with the DVM connected across the current

monitoring resistor.

Summary of Contents for 6541A

Page 12: ...12 Verification Figure 2 1 Basic Test Setup CV TESTS CV TESTS ...

Page 18: ...18 Verification Figure 2 3 CC RMS Noise Measurement Test Setup ...

Page 30: ......

Page 32: ...32 Troubleshooting Figure 3 1 Top View with Cover Removed for 655xA 665xA Models Sheet 1 of 2 ...

Page 33: ...Troubleshooting 33 Figure 3 1 Top View with Cover Removed for 655xA 665xA Models Sheet 2 of 2 ...

Page 37: ...Troubleshooting 37 Figure 3 2 Overall Troubleshooting Flow Diagram Sheet 1 of 4 ...

Page 38: ...38 Troubleshooting Figure 3 2 Overall Troubleshooting Flow Diagram Sheet 2 of 4 ...

Page 39: ...Troubleshooting 39 Figure 3 2 Overall Troubleshooting Flow Diagram Sheet 3 of 4 ...

Page 40: ...40 Troubleshooting Figure 3 2 Overall Troubleshooting Flow Diagram Sheet 4 of 4 ...

Page 51: ...Troubleshooting 51 Figure 3 5 No Display Troubleshooting ...

Page 52: ...52 Troubleshooting Figure 3 6 OV Will Not Fire Troubleshooting ...

Page 53: ...Troubleshooting 53 Figure 3 7 OV At Turn On Troubleshooting Sheet 1 of 2 ...

Page 54: ...54 Troubleshooting Figure 3 7 OV At Turn On Troubleshooting Sheet 2 of 2 ...

Page 55: ...Troubleshooting 55 Figure 3 8 Output Held Low Troubleshooting Sheet 1 of 2 ...

Page 56: ...56 Troubleshooting Figure 3 8 Output Held Low Troubleshooting Sheet 2 of 2 ...

Page 57: ...Troubleshooting 57 Figure 3 9 Output Held High Troubleshooting ...

Page 58: ...58 Troubleshooting Figure 3 10 DAC Circuits Troubleshooting ...

Page 60: ...60 Troubleshooting Figure 3 13 Serial Down Troubleshooting Sheet 1 of 2 ...

Page 61: ...Troubleshooting 61 Figure 3 13 Serial Down Troubleshooting Sheet 2 of 2 ...

Page 62: ...62 Troubleshooting Figure 3 14 Secondary Down Troubleshooting Sheet 1 of 2 ...

Page 63: ...Troubleshooting 63 Figure 3 14 Secondary Down Troubleshooting Sheet 2 of 2 ...

Page 64: ...64 Troubleshooting Figure 3 15 Slow Down Programming Troubleshooting ...

Page 65: ...Troubleshooting 65 Figure 3 16 Isolator Board Circuits Troubleshooting ...

Page 80: ......

Page 87: ...Principles of Operation 87 Figure 4 4 Output Power and Control Circuits ...

Page 94: ......

Page 136: ......

Page 145: ...Figure 6 1 Power Supply Interconnection Diagram for All Models ...

Page 146: ...Figure 6 2 AC Power Distribution Diagram for 655xA 665xA Models ...

Page 147: ...Figure 6 3 GPIB Board Assembly Diagram sheet 1 of 2 ...

Page 148: ...2 3 4 1 6 5 7 8 Figure 6 3 GPIB Board Schematic Diagram sheet 2 of 2 ...

Page 149: ...Figure 6 4 Front Panel Board Assembly Diagram sheet 1 of 2 ...

Page 150: ...Figure 6 4 Front Panel Board Schematic Diagram sheet 2 of 2 ...

Page 152: ...Figure 6 5 A1 Main Board Assembly Diagram for 654xA 664xA Models Only ...

Page 160: ...Figure 6 6 Left Tunnel Circuits Schematic Diagram for 654xA 664xA Models Only sheet 2 ...

Page 162: ...Figure 6 7 Right Tunnel Circuits Schematic Diagram for 654xA 664xA Models Only sheet 2 ...

Page 164: ......

Page 168: ......