2-13

Making Measurements

Cleaning Connections for Accurate Measurements

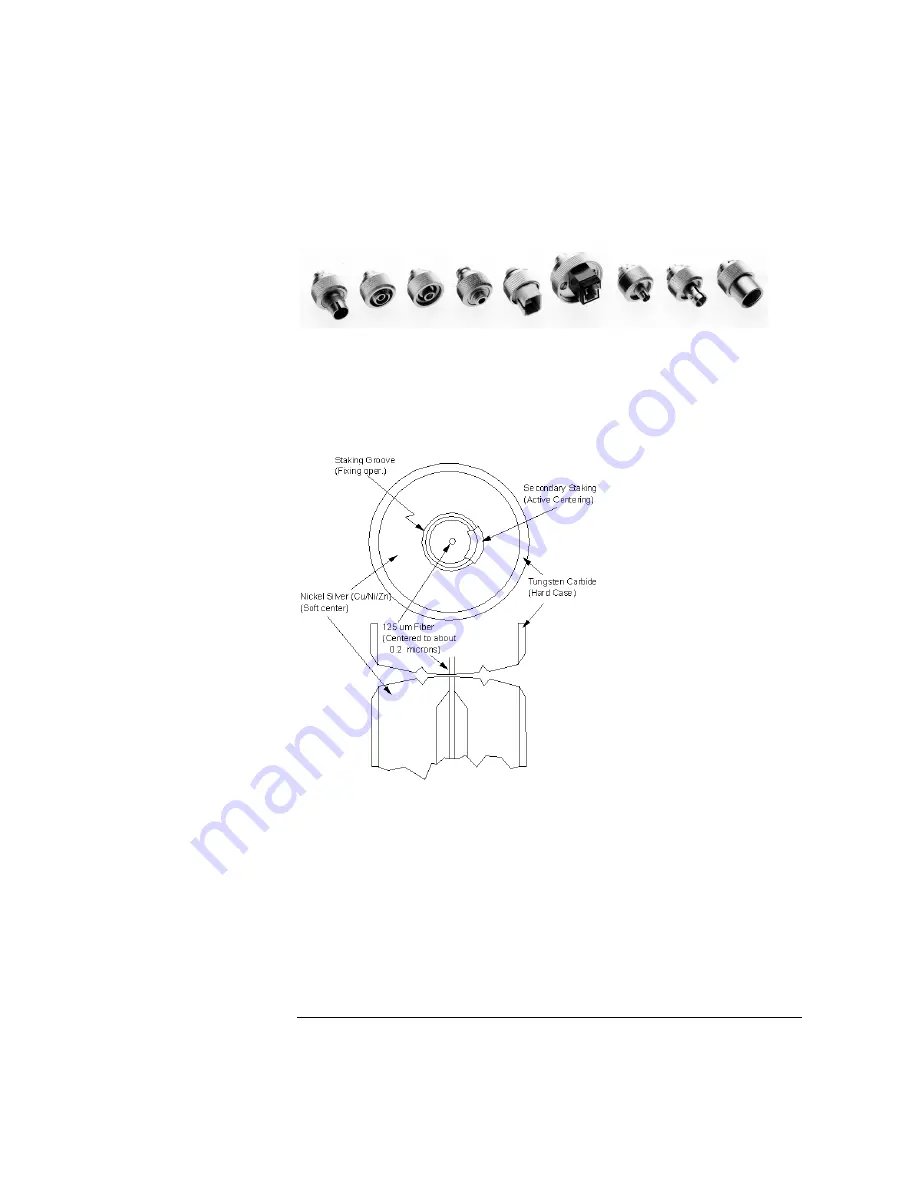

Figure 2-2. Universal adapters to Diamond HMS-10.

The HMS-10 encases the fiber within a soft nickel silver (Cu/Ni/Zn) center

which is surrounded by a tough tungsten carbide casing, as shown in

.

Figure 2-3. Cross-section of the Diamond HMS-10 connector.

The nickel silver allows an active centering process that permits the glass fiber

to be moved to the desired position. This process first stakes the soft nickel

silver to fix the fiber in a near-center location, then uses a post-active staking

to shift the fiber into the desired position within 0.2

µ

m. This process, plus the

keyed axis, allows very precise core-to-core alignments. This connector is

found on most Agilent Technologies lightwave instruments.

Summary of Contents for 83437A

Page 1: ...Agilent 83438A Erbium ASE Source User s Guide ...

Page 5: ...v The Agilent 83438A At a Glance Rear view of instrument ...

Page 8: ......

Page 10: ......

Page 24: ...2 4 Making Measurements Performing Stimulus Response Measurements ...

Page 41: ...3 Specifications 3 3 Regulatory Information 3 6 Specifications and Regulatory Information ...

Page 48: ......

Page 54: ......

Page 61: ...5 7 Servicing General Information ...

Page 63: ...5 9 Servicing General Information ...

Page 79: ...5 25 Servicing Adjustment Procedure ...

Page 85: ...5 31 Servicing Replacing Instrument Assemblies Location of resistors R2 R8 and R9 ...

Page 92: ...5 38 Servicing Replaceable Parts ...

Page 94: ...5 40 Servicing Replaceable Parts ...

Page 96: ...5 42 Servicing Replaceable Parts ...

Page 98: ...5 44 Servicing Replaceable Parts ...

Page 100: ...5 46 Servicing Replaceable Parts ...

Page 106: ......