Chapter 2

163

Making Adjustments

27. Checking the Absolute Amplitude Accuracy for Option 051

Frequency Range 810 MHz to 956 MHz

Frequency Response Input Attenuator 10 dB

10. Set the frequency of the analyzer to the first measurement

frequency shown in

11.On the synthesized sweeper, press CW and set the frequency to the

same measurement frequency as the analyzer is set in the previous

step.

12.On the analyzer, press

PEAK SEARCH

.

13.On the synthesized sweeper, press

POWER LEVEL

and adjust the

output amplitude so the analyzer marker amplitude reads

−

9 dBm

±

0.05 dB.

14.Set the power sensor cal factor (for frequency being measured) on

the measuring receiver, then record the measuring receiver power

reading in

.

15.Repeat

to

for frequencies of 826 MHz, 940 MHz, and

956 MHz. Record the results in

. The results should be

within the limits shown.

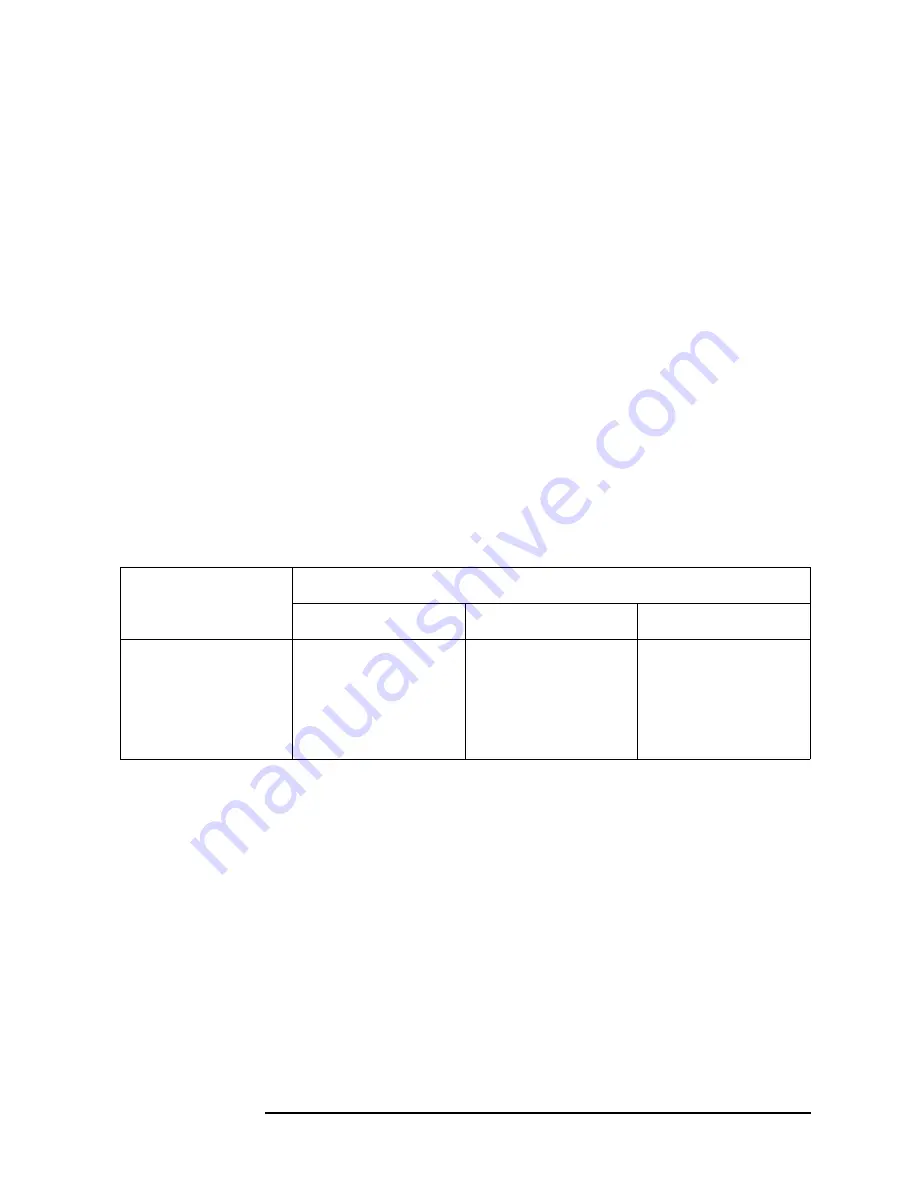

Table 2-18

Frequency Response Attenuator 10 dB

Synthesized

Sweeper Frequency

(MHz)

Measuring Receiver

Min (dBm)

Reading (dBm)

Max (dBm)

810

−

9.6

_________________

−

8.4

826

−

9.6

_________________

−

8.4

940

−

9.6

_________________

−

8.4

956

−

9.6

_________________

−

8.4

Summary of Contents for 8590L

Page 29: ...30 Chapter1 Introduction If You Replace or Repair an Assembly ...

Page 175: ...176 Chapter2 Making Adjustments 28 Correcting for Absolute Amplitude Accuracy for Option 051 ...

Page 279: ...280 Chapter5 Troubleshooting the IF Section Troubleshooting the A15 Motherboard Assembly ...

Page 347: ...348 Chapter7 Replacing Major Assemblies Rear Frame Assembly ...

Page 355: ...356 Chapter8 If You Have A Problem Returning Your Analyzer for Service ...

Page 379: ...380 Chapter9 Assembly Descriptions and Block Diagrams IF Section ...

Page 380: ......

Page 381: ...382 Chapter9 Assembly Descriptions and Block Diagrams IF Section ...

Page 382: ......

Page 383: ...384 Chapter9 Assembly Descriptions and Block Diagrams IF Section ...

Page 384: ......

Page 385: ...386 Chapter9 Assembly Descriptions and Block Diagrams IF Section ...

Page 386: ......

Page 387: ...388 Chapter9 Assembly Descriptions and Block Diagrams IF Section ...

Page 388: ......

Page 389: ...390 Chapter9 Assembly Descriptions and Block Diagrams IF Section ...

Page 390: ......

Page 391: ...392 Chapter9 Assembly Descriptions and Block Diagrams IF Section ...

Page 392: ...393 10 Analyzer Options and Block Diagrams ...

Page 443: ...444 Chapter10 Analyzer Options and Block Diagrams Option 190 DVB C Service Menus ...

Page 444: ......

Page 445: ...446 Chapter10 Analyzer Options and Block Diagrams Option 190 DVB C Service Menus ...

Page 446: ......

Page 447: ...448 Chapter10 Analyzer Options and Block Diagrams Option 190 DVB C Service Menus ...

Page 448: ......

Page 449: ...450 Chapter10 Analyzer Options and Block Diagrams Option 190 DVB C Service Menus ...

Page 451: ...452 Chapter10 Analyzer Options and Block Diagrams Option 190 DVB C Service Menus ...

Page 483: ...484 Chapter11 Major Assembly and Cable Locations Major Assembly and Cable Locations ...

Page 537: ...538 Chapter12 Replaceable Parts Component Level Information Packets ...

Page 538: ......

Page 539: ...540 Chapter12 Replaceable Parts Component Level Information Packets ...

Page 540: ......

Page 541: ...542 Chapter12 Replaceable Parts Component Level Information Packets ...

Page 542: ...FOLDOUT 12 3 8590L AND 8591E RF ASSEMBLY ...

Page 543: ...544 Chapter12 Replaceable Parts Component Level Information Packets ...

Page 544: ......

Page 545: ...546 Chapter12 Replaceable Parts Component Level Information Packets ...

Page 546: ......

Page 547: ...548 Chapter12 Replaceable Parts Component Level Information Packets ...

Page 548: ......

Page 549: ...550 Chapter12 Replaceable Parts Component Level Information Packets ...

Page 550: ......

Page 551: ...552 Chapter12 Replaceable Parts Component Level Information Packets ...

Page 665: ...666 Chapter15 Service Equipment and Tools Service Equipment and Tools ...

Page 666: ...667 16 Safety and Regulatory Information ...

Page 673: ...674 Chapter16 Safety and Regulatory Information Protection from Electrostatic Discharge ...