General Safety Considerations

Setting Up the 86122A

Agilent 86122A

Multi-Wavelength Meter

, Second Edition

25

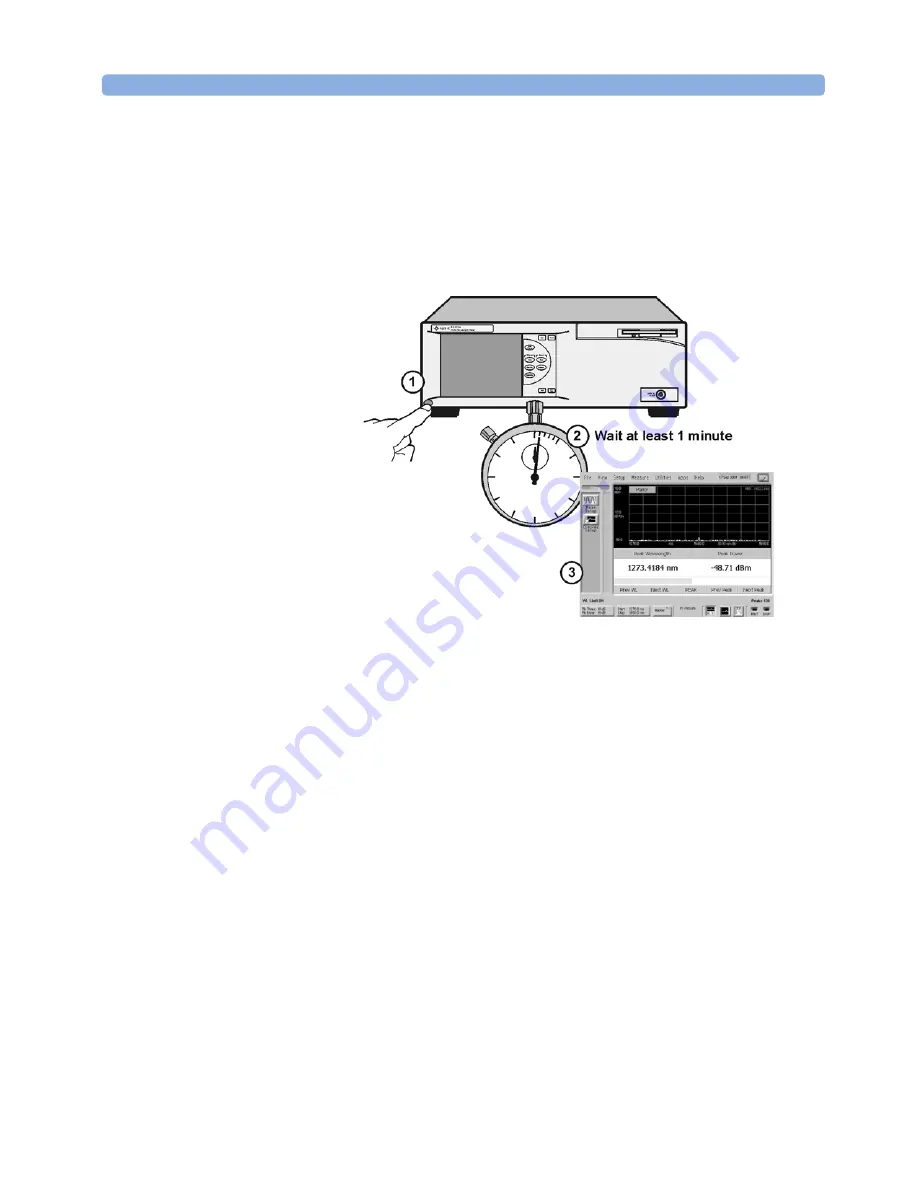

Step 6. Turn On the Line Power

Press the power switch at the lower left-hand corner of the front panel.

After at least one minute, the display will look similar to the following

figure.

The Agilent Variable Optical Attenuator modules and Agilent Variable

Optical Attenuator modules with Power Control is ready to use!

Summary of Contents for 86122A

Page 1: ...Agilent Technologies Agilent 86122A Multi Wavelength Meter User s Guide ...

Page 8: ...8 Agilent 86122A Multi Wavelength Meter Second Edition ...

Page 74: ...Using the 86122A Menus 74 Agilent 86122A Multi Wavelength Meter Second Edition The Help menu ...

Page 92: ...Using the 86122A Making Measurements 92 Agilent 86122A Multi Wavelength Meter Second Edition ...

Page 111: ......